Struggling with high costs for large metal parts? You need strong components, but precision methods are too expensive. Sand casting offers a reliable, cost-effective solution for many projects.

Sand casting is a versatile method where molten metal is poured into a sand mold. It's known for being economical and fast. It’s great for large parts, complex shapes, and works with many metals, making it perfect for small to medium-volume orders.

I’ve spent my career working with metal, starting right on the shop floor. Sand casting is one of the oldest methods, but it's still incredibly important. If you’re a sourcing manager, you need to know exactly where it fits in your supply chain. Let's break down the details so you can make the best choice for your components.

What Is Sand Casting?

Do all the different casting terms get confusing? Investment, die, sand... it's a lot. Let's start with the foundation: sand casting.

Sand casting uses a mold made from compressed sand. We pour liquid metal into the mold cavity, let it cool, and then break the sand mold away to get the final part. It's a "expendable mold" process because the mold is used only once.

When I first started on the shop floor, sand casting was the first process I learned. It’s the backbone of the metal industry for a reason. The concept is simple: sand is cheap, easy to shape, and can handle very high temperatures. This simplicity is its greatest strength.

It’s not just for old-fashioned parts, though. We use modern sand binders and techniques to improve the process. But the core idea hasn't changed in centuries. You create a "pattern" (a replica of the part), press it into the sand to make an impression (the cavity), and that’s your mold.

Why Sand is the Key Material

Sand is a refractory material1. This just means it doesn't melt or break down when you pour 1500°C liquid steel into it. It also allows gases to escape as the metal solidifies, which helps prevent defects like porosity. We mix the sand with a binder, like clay (green sand) or chemical resins (no-bake), to make it hold its shape. For a sourcing manager, understanding this helps you ask the right questions about what type of sand process a foundry uses.

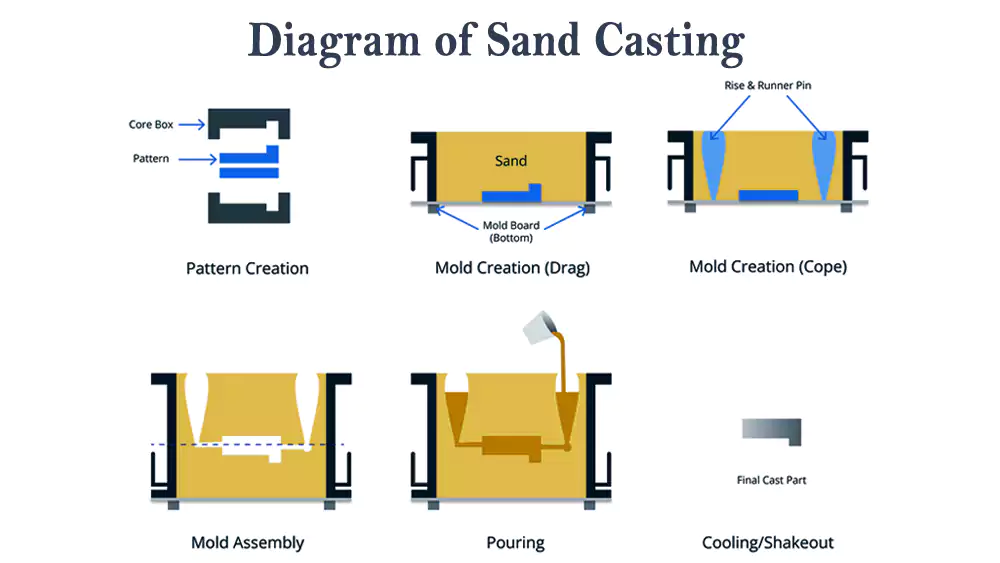

How sand casting works?

Is the definition clear, but the actual process still a bit fuzzy? Seeing the steps in order makes it all click. Let’s walk through it.

First, we make a pattern of the part. We pack sand around this pattern in a box called a "flask." We remove the pattern, leaving a cavity. We pour molten metal into the cavity, let it cool, and then break the sand mold to retrieve the part.

I always find it helps to think of this as a step-by-step manufacturing flow. As a manager evaluating a supplier, you'd want to see how they control each stage.

1. Pattern Making

This is the most critical first step. The pattern is a high-quality model of your part, usually made of wood, plastic, or metal. It has to be slightly larger than the final part to account for metal shrinkage as it cools. This "shrinkage allowance" is something we calculate very carefully.

2. Mold Making and Cores

We place the pattern in the flask and pack the special molding sand tightly around it. If your part is hollow (like an engine block), we use a "core." A core is a separate piece made of sand that we place inside the mold cavity. The liquid metal flows around the core, creating the internal empty space.

3. Pouring and Cooling2

This is the part everyone thinks of. We melt the metal to a specific temperature and pour it steadily into the mold. Then, we wait. Cooling time is crucial; it can range from minutes to days for very large castings. Rushing this causes stress and cracks in the part.

4. Shakeout and Finishing

Once cool, we break the mold. This is often done on a vibrating "shakeout" machine. The sand is knocked away, leaving the raw casting. The part then goes to finishing. We cut off the extra metal from the pouring system (the "gates" and "risers"), and then often shot-blast it to clean the surface. From there, it might go to heat treatment3 or CNC machining.

What Is Molding Sand? Types & Key Properties?

Thinking any sand will do? The sand from the beach won't hold molten steel. The type of sand and binder we use directly controls the quality of your part.

Molding sand is special sand mixed with a binder to hold its shape. The most common types are "green sand" (sand, clay, water) and "no-bake" or "resin-bonded" sand (sand, chemical binder). The choice depends on the metal, part size, and required surface finish.

The sand itself isn't just sand; it's the system of sand and binders that matters. When I'm evaluating a new sand process, I look at several key properties. These directly impact the final part's quality, something a technical manager would be validating.

Key Properties of Molding Sand

- Strength: It must be strong enough to hold the weight of the liquid metal without collapsing.

- Permeability4: This is key. It means the sand is porous enough to let hot gases escape. If gas is trapped, you get "blowholes," a major defect.

- Thermal Stability: It can't break down or melt when the hot metal hits it.

- Collapsibility: After the metal cools, the sand needs to break apart easily during shakeout. If it's too hard, it can cause "hot tears" or cracks as the metal shrinks.

Common Sand Systems

We mostly use two systems in the foundry:

| Sand System | Binder | Key Characteristics | Best Use |

|---|---|---|---|

| Green Sand5 | Clay and Water | Cheap, fast, reusable (sand is recycled). | High-volume, small to medium parts (e.g., automotive). |

| No-Bake (Resin) | Chemical Binders | Cures at room temp. Stronger mold, better surface finish. | Large, complex parts; low-volume orders; (e.g., large pump housings). |

For high-performance aerospace or energy parts , a resin-bonded sand is often preferred because it creates a more stable mold, leading to better dimensional accuracy.

How Sand Molds Create Complex Castings?

Do you think sand casting is just for simple shapes like bricks or anchors? Many people do. But this process can create incredibly complex geometries, like engine blocks.

Sand casting handles complexity by using "cores." Cores are separate, solid sand inserts placed inside the mold. They block the metal from flowing into certain areas, creating internal passages, undercuts, and hollow sections that would be impossible to mold otherwise.

The secret to complexity isn't the outer mold; it's the cores. I've worked on projects that used over 20 individual cores assembled like a 3D puzzle to create a single mold.

The Power of Cores

A core is made of sand, just like the mold, but it's typically made using a no-bake or resin process so it's very hard and durable. Think of an engine block. All those internal waterways for coolant? Those are all created by intricate sand cores6.

The process looks like this:

- We create the main mold cavity for the outside of the part.

- We place the pre-made sand cores inside this cavity. They are held in place by "core prints," which are small extensions that sit in matching recesses in the mold.

- We close the mold, and the cores are now suspended inside the empty space.

- When we pour the metal, it fills the space between the mold wall and the core.

After shakeout, the part is hollow. We then have to remove the sand from inside the part, often by vibrating it or using high-pressure water. This is why a supplier's core-making and removal process is a critical point to audit for complex parts.

Metals Commonly Used in Sand Casting?

Need a part made from a specific high-performance alloy? You might worry sand casting can't handle it. In fact, this process is one of the most versatile for metal types.

Sand casting works with almost any metal. The most common are iron (ductile and gray iron) and aluminum. It is also used heavily for steels (carbon and stainless), brass, and bronze. The sand's high melting point makes it ideal for metals requiring high pouring temperatures.

One of the biggest advantages of sand casting is that it's not limited by the metal. Unlike die casting, which is mostly for lower-temp metals like aluminum, sand can handle the extreme heat of steel and iron.

Ferrous Metals (Iron-Based)

This is the bread and butter of sand casting.

- Gray Iron: Cheap, good at damping vibration. Used for machine bases, engine blocks.

- Ductile Iron: More flexible and stronger than gray iron. Used for pipes, gears, and suspension parts.

- Carbon & Stainless Steels: Used when high strength, corrosion resistance, or heat resistance is needed. This is common in the energy sector for valves and pump bodies.

Non-Ferrous Metals

- Aluminum Alloys: Lightweight and corrosion-resistant. Very common for automotive parts like intake manifolds.

- Bronze & Brass: Good corrosion resistance and self-lubricating properties. Used for bearings, bushings, and marine fittings.

When you're sourcing , the key question for your supplier isn't just "Can you cast this metal?" It's "How do you control the melt?" You need to ensure they have the right equipment (like an spectrometer) to verify the alloy's chemical composition before they pour. This is essential for meeting material certifications.

Accuracy of Sand Casting: Tolerances & Surface Finish?

Need a part with very tight tolerances? You might be wondering if sand casting is too "rough" for your job. Let's look at the real numbers you can expect.

Sand casting is not a high-precision process like investment casting. Typical tolerances are around +/- 0.030" (0.76mm) for the first inch, plus extra for larger dimensions. The surface finish is also rough, often 125-250 RMS, due to the sand grain size.

This is where I have to be very clear with customers. If you need the sharp, clean finish of my investment castings, sand casting is not the right first step. The sand grains leave a noticeably grainy texture on the part.

Understanding Tolerances

The accuracy of a sand casting depends on many factors: the quality of the pattern, the type of sand (resin sand is better than green sand), and the skill of the foundry. As a general rule, it's a "near-net shape" process, not a "net-shape" one. This means you must design the part with extra material (called "machine stock") on any surface that needs to be precise. The casting gets you 90% of the way there; machining finishes the job.

Here are some typical expectations:

- Linear Tolerances: A good starting point is +/- 1/32" or about 0.8mm.

- Surface Finish (RMS): 125-250 µin (3.2-6.3 µm) is common.

- Wall Thickness: It's hard to get very thin walls. I'd recommend a minimum of 0.25" (6mm) for most parts.

For a Sourcing Manager, this means you must clearly mark on your drawings which surfaces are "as-cast" and which are "finish-machined." This avoids costly misunderstandings.

Advantages and Limitations of Sand Casting?

So, when should you actually choose sand casting? It’s powerful, but it's not the solution for everything. Let’s look at the pros and cons honestly.

The main advantages are low tooling cost, fast lead times for simple parts, and the ability to make very large components. The main limitations are its poor dimensional accuracy and rough surface finish, which often require secondary machining operations.

In my company, we offer several casting methods, so I always try to guide customers to the right process for their project, not just the one they ask for. Here is how I break down sand casting.

Advantages (The "Why You Should")

- Low Tooling Cost: Making a wood or plastic pattern is thousands of dollars cheaper than making the steel die for die casting. This is perfect for low-volume or prototype runs.

- Size: This is the biggest one. Want to cast a 10-ton engine block? Sand casting is one of the only ways to do it.

- Metal Versatility: As we discussed, it works with almost any metal, especially high-temp steels and irons.

- Complexity: Cores allow for complex internal geometries.

Limitations (The "Why You Shouldn't")

- Poor Tolerances/Finish: This is the main trade-off. It's just not a precision process. It requires machining.

- Lower Production Rate: It's slower per-part than die casting because you have to make a new mold for every single part.

- Labor Intensive: Packing sand, setting cores, and shakeout require more manual labor.

For a manager balancing cost and performance, sand casting is the clear choice when part size or low volume is the main driver, and you already plan to machine the critical surfaces.

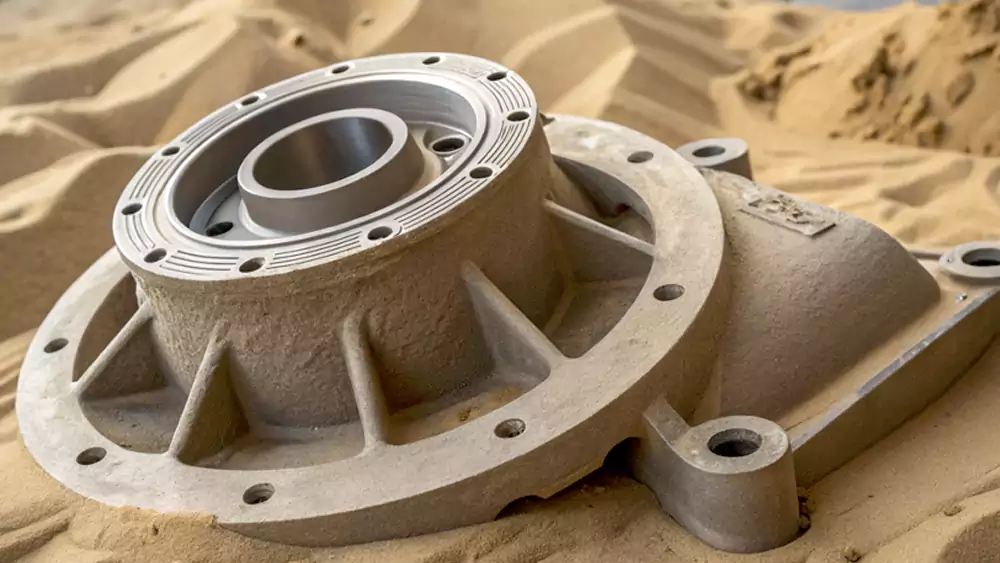

Case Study: Custom Industrial Sand-Cast Component?

Does all this theory make sense, but you need a practical example? Theory is nice, but data is better. Here’s a look at a real-world component.

We had a client in the energy sector who needed a large pump housing. It had to withstand high pressure and was a low-volume order. Sand casting was the only logical choice, allowing us to produce the complex internal channels affordably.

I remember a project from a few years ago that really shows where sand casting shines. A client in the energy sector came to us. They needed a complex manifold for a fluid handling system.

The Challenge

The part was about 2 feet long and weighed 85 lbs. It had three separate internal channels that could not mix. The original design was a nightmare of welded pipes, which was expensive and had too many potential failure points (the welds). They needed a single, cast-in-one-piece solution, but their order was only for 50 units. Making a tool for investment casting or die casting was far too expensive.

Our Solution: Resin Sand Casting

We chose a no-bake (resin) sand process for this. The 'green sand' process wouldn't hold the tight tolerances needed for the internal channels. We designed a complex core assembly—it took three separate cores, interlocked, to form the internal passages.

Here are the project details:

| Parameter | Specification |

|---|---|

| Project: | Fluid Control Manifold |

| Alloy: | CF8M (Cast 316 Stainless Steel) |

| Casting Process: | No-Bake (Resin) Sand Casting |

| Part Weight: | 85 lbs (38.5 kg) |

| Key Challenge: | Three complex, non-intersecting internal channels |

| Core Design: | 3-part assembled resin-bonded core |

| Tolerance (As-Cast): | +/- 0.050" (1.27 mm) |

| Tolerance (Machined): | +/- 0.005" (0.13 mm) on flange faces |

| Quality Check: | 100% pressure testing of each channel |

We delivered the parts as "near-net shape." The client only had to machine the flange faces. We validated the quality by pressure-testing every single part to ensure the internal walls were solid. The client saved over 40% compared to the fabricated pipe assembly.

Sand Casting vs. Other Casting Processes?

With so many casting options, how do you choose? Sand, investment, die casting... it's a lot. Here’s a simple cheat sheet I use to explain it.

Sand casting is for large parts and low tooling costs, but has a rough finish. Investment casting (my specialty) has high precision and a great finish but costs more. Die casting is for high-volume, non-ferrous parts (like aluminum) but has the highest tooling cost.

As a sourcing manager, choosing the right process is the most important decision you'll make to control cost and quality. I run an investment casting company, so I'm an expert in high-precision, but I have deep respect for what sand casting can do.

Sand Casting vs. Investment Casting

- Sand Casting: Think big and rough. Use this for large machine bases, pump housings, or engine blocks. Tooling is cheap, parts are cheap, but you must machine the details.

- Investment Casting: Think small and precise. This is what we do at Allied Metal. We use a ceramic shell to get very fine details, excellent surface finish, and tight tolerances, often eliminating machining. It's for complex, high-value parts like turbine blades or medical implants.

Sand Casting vs. Die Casting

- Sand Casting: Think low volume and any metal. Use this for 10, 50, or 500 parts. It works great for steel and iron.

- Die Casting: Think high volume and non-ferrous. Use this when you need 100,000 aluminum parts. The steel mold is very expensive, but the per-part cost is pennies and it's extremely fast.

Here is a simple table I use:

| Feature | Sand Casting | Investment Casting | Die Casting |

|---|---|---|---|

| Tooling Cost | Low | Medium | Very High |

| Per-Part Cost | Medium-Low | High | Very Low (at volume) |

| Surface Finish | Poor | Excellent | Good |

| Tolerance | Poor | Excellent | Good |

| Metals | All | All | Low-temp (Al, Zn) |

| Max Size | Very Large | Small-Medium | Small-Medium |

| Best For... | Large parts, prototypes | Complex, precise parts | High-volume parts |

Conclusion

Sand casting is a powerful, flexible, and economical process. It's the best choice for large parts, low volumes, and complex internal shapes when you can accept a rougher finish.

-

Learn about refractory materials to grasp their role in preventing defects in metal casting and enhancing product quality. ↩

-

Exploring the Pouring and Cooling process reveals critical factors that influence the integrity and durability of cast metal parts. ↩

-

Understanding Steel Heat Treatment: The Key Technology for Enhancing Material Properties ↩

-

Understanding permeability is crucial for preventing defects in metal casting, ensuring quality and efficiency. ↩

-

Exploring green sand benefits can enhance your knowledge of cost-effective and efficient molding techniques in foundries. ↩

-

Understanding sand cores is essential for grasping their role in creating complex parts in manufacturing. ↩