In this article, we will discuss with you the future trends of casting! The changes in manufacturing brought about by artificial intelligence, high-performance materials and personalization!

1. What is casting?

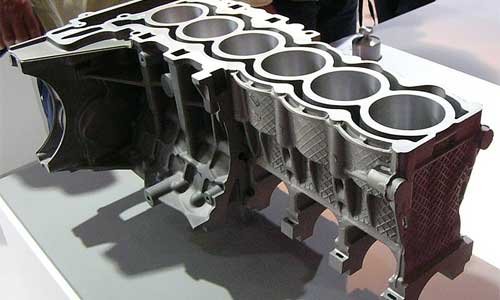

Casting is a manufacturing process where molten material, usually metal, is poured into a mold to solidify and take its shape. Once cooled, the material forms a part that matches the mold’s design.

It’s widely used for producing parts with complex shapes and is commonly found in industries like automotive, aerospace, and machinery due to its ability to create durable and precise components.

Common types of casting processes

The casting process can be categorized into various types based on characteristics and application needs. Common methods include:

Sand casting:

Uses sand as the mold material, ideal for mass production and lower costs.

Investment (precision) casting:

Involves creating molds from wax or other soluble materials, offering high precision and is suitable for small batch production of intricate parts.

Die casting:

Molten metal is injected into metal molds, allowing for rapid cooling and solidification, making it ideal for producing precise, smooth-surfaced parts.

Low-pressure casting:

Applies low pressure to push molten metal into molds, commonly used for aluminum alloy components.

Each casting method is tailored to specific production needs, including product complexity, volume, and precision requirements.

History

- 3000 BC: The first use of casting technology, primarily for making bronze and weapons.

- 2000 BC: Bronze casting became common, with civilizations crafting tools and ornaments from bronze.

- 500 BC: The introduction of iron casting, with cast iron used in construction and weaponry.

- 18th century: The Industrial Revolution led to advancements in metalworking, including mass production of steel and cast iron.

- 19th century: Precision techniques were developed, allowing the production of high-precision parts.

- Early 20th century: Die-casting technology emerged, using high pressure to form finer, more detailed parts.

- Mid-20th century: The integration of CNC technology improved production accuracy and efficiency.

- 21st century: Innovations in environmental protection and smart technologies have shaped modern metal forming processes.

2. Intelligent and automated cast parts

With the arrival of Industry 4.0, the production process of casting parts also ushered in a new era of intelligence and automation.

- Automated production lines and intelligent monitoring systems have become standard in foundries.

- Robots replace manual labor for pouring, mold picking and cleaning, greatly improving productivity and part consistency.

Meanwhile, through sensors and data acquisition systems, key parameters such as temperature and pressure in the casting process can be monitored in real time and automatically adjusted as needed, thus improving the precision and quality of cast parts.

3. Green casting: environmentally friendly technology and sustainable development

As environmental regulations tighten, green practices in casting are becoming increasingly important. This approach not only reduces pollution but also focuses on using eco-friendly materials and processes.

For example, renewable materials, low-pollution sand, and energy-efficient melting technologies are helping to minimize the environmental impact of casting.

This shift also supports sustainable development, encouraging the casting industry to adopt more environmentally responsible and resource-efficient practices, benefiting both the environment and future manufacturing.

4. Application of high-performance casting materials

High-performance casting materials not only need to have excellent mechanical properties, but also to meet the special needs of high temperature resistance, corrosion resistance, lightweight and so on. Below are several common high-performance casting materials and their applications:

High-temperature alloys

Characteristics: High-temperature alloys (such as nickel-based and cobalt-based alloys) have excellent high-temperature strength, oxidation resistance and creep resistance, and are able to maintain stability in extreme temperature environments.

Applications: Widely used in the aerospace field for the manufacture of turbine blades, combustion chamber components, etc.; in the energy industry for gas turbines, nuclear reactor components; also used in the automotive industry for high-performance engine exhaust systems and turbochargers.

Titanium alloys

Properties: Titanium alloys have high strength, low density, excellent corrosion resistance and biocompatibility, making them ideal for lightweight designs.

Applications: It is mainly used in aerospace, manufacturing aircraft structural parts and engine components; in the medical industry for implants such as artificial joints and bone plates; and in the chemical industry for corrosion-resistant pumps, valves and pipelines.

Aluminum alloy

Properties: Aluminum alloy has light weight, high specific strength, good thermal conductivity and corrosion resistance, and is easy to process and form.

Applications: In the automotive industry, aluminum alloys are used for engine blocks, wheel hubs, and body structural parts; in the aerospace field, they are used for lightweight parts such as aircraft skins and frames; in the electronics industry, they are used for radiators, housings, etc.

Magnesium alloy

Characteristics: Magnesium alloys are currently the lightest metal structural materials with high specific strength, good shock absorption and electromagnetic shielding properties.

Applications: In the automotive industry, magnesium alloys are used for lightweight components such as transmission housings, steering wheel skeletons, etc.; in aerospace, magnesium alloys are used for satellite mounts and missile components; in consumer electronics, they are used for laptop housings, cell phone frames, etc.

Stainless steel

Properties: Stainless steel has excellent corrosion resistance, high strength and good workability, suitable for a wide range of complex environments.

Applications: In the medical industry, stainless steel is used for surgical instruments and implants; in the food industry, it is used for processing equipment and storage containers; and in the chemical industry, it is used for corrosion-resistant pumps and valves, reactors and so on.

5. Quality control and accuracy improvement of cast parts

In the production of cast parts, quality control is always a top priority.

Modern technology incorporates advanced inspection equipment and intelligent control systems, such as X-ray inspection, laser scanning, and computer-aided detection, to accurately identify defects and ensure the quality of each component.

Additionally, the development of precision techniques has raised the standards for shape, size, and surface finish, enabling cast parts to meet the increasing demands of precision industry standards.

6. The rise of personalization and small batch production

As market demand shifts towards customization and small-batch production, personalization has become a central trend in the industry.

While traditional methods focused on mass production, the sector is now adopting digital technologies and 3D printing to enhance the efficiency of small-batch manufacturing.

With the help of advanced design software, customers can tailor specifications, materials, and processes, providing more flexible solutions to meet a wide range of needs.

7. Prospects for industrial applications of castings

Cast parts are widely used across various industries and will continue to play a vital role in the future.

In the automotive sector, the demand for such components is particularly high, especially with the rise of electric and smart vehicles, where lightweight materials are becoming increasingly sought after.

In aerospace, these components are exposed to extreme operating conditions, necessitating higher-performance materials and greater precision.

Additionally, industries such as energy, healthcare, and machinery are also seeing increased demand for these specialized parts, driving ongoing advancements in production technology.

8. Summary

As a crucial element of modern manufacturing, cast parts are evolving towards greater intelligence, environmental sustainability, high performance, and personalization. With continuous technological advancements, both casting processes and materials are innovating, resulting in parts that are more precise, efficient, and eco-friendly.

For the manufacturing sector, these innovations are essential not only for boosting productivity but also for meeting market demands and fostering sustainable development.