You’re reviewing a new component design. It has complex internal channels, thin walls, and needs to withstand high stress. Machining it from a solid block would be a waste of time and material. Forged or welded? Not feasible for this geometry. This is the exact moment where casting becomes your most powerful tool. It's the process that makes the impossible, possible.

Casting is a foundational manufacturing process where liquid material is poured into a hollow mold to create a solid, complex part. For metals, this method uniquely delivers intricate shapes, excellent material properties, and cost-effectiveness, especially for medium to high volumes.

For years, I worked alongside professionals like Michael—engineers and buyers under pressure to source perfect parts. The biggest hurdle was always matching the design to the right process. A mismatch leads to budget overruns, failed prototypes, and delayed launches. This guide is designed to be your clear roadmap. We’ll break down how casting works, explore the main types and materials, and provide a practical framework for selection. Let's build the knowledge you need to specify cast components with confidence.

What is Casting?

When a part's geometry defies simple manufacture—think of a hollow turbine blade with cooling channels or an ornate architectural fixture—you need a method that creates form in one single step.

Casting is a transformative manufacturing method. It involves pouring liquid material into a pre-shaped cavity (a mold). The material solidifies there, taking the mold’s exact geometry to produce a near-net-shape part.

Think of it as the opposite of machining. Machining cuts away material to reveal a shape. Casting builds the shape up by adding material into a predefined space. This core difference is why casting is unbeatable for creating complex internal features, hollow sections, and parts that would be too weak or wasteful if made from a solid block. While it can use various materials, metal casting is the backbone of heavy industry. The type of mold—from simple sand to precision steel—defines the entire process, its cost, and its outcome.

How does metal casting work?

You’ve received two quotes for the same part. One has low tooling but a high per-part cost. The other has significant upfront tooling but a very low piece price. Understanding the steps of casting explains this puzzle and shows you where value—and risk—are built into the process.

Metal casting follows a defined sequence: make a pattern, create a mold, pour molten metal, control solidification, and finish the part. Variations in these steps create different casting processes with unique trade-offs between speed, precision, and cost.

Let's follow this universal sequence:

- Pattern Creation: A physical model of the final part is made, often slightly larger to account for metal shrinkage. The pattern material (wood, plastic, wax) depends on the casting process.

- Mold Formation1: This is where processes diverge dramatically. The pattern is used to create a negative cavity. In sand casting, it’s packed in bonded sand. In investment casting, it’s coated in ceramic to form a shell. The mold must survive intense heat and allow gases to escape.

- Metal Pouring: The alloy is melted to a precise temperature in a furnace. It is then poured into the mold cavity. Temperature control here is critical for proper flow and final quality.

- Solidification2: This is the most critical phase. The metal must cool and solidify in a controlled way. Poor control causes defects like porosity (small holes) or internal stress. This step separates great foundries from average ones.

- Finishing: The solidified casting is removed from the mold in a “shakeout.” Then, feeders, gates, and risers (excess material channels) are cut off. The part is cleaned (e.g., shot blasted) and often undergoes machining on critical surfaces.

A high upfront tooling cost, like in die casting, buys you a durable steel mold capable of making millions of identical parts at high speed. A low tooling cost, like in sand casting, means a simpler, disposable mold suited for prototypes or low volumes, with more labor required per part.

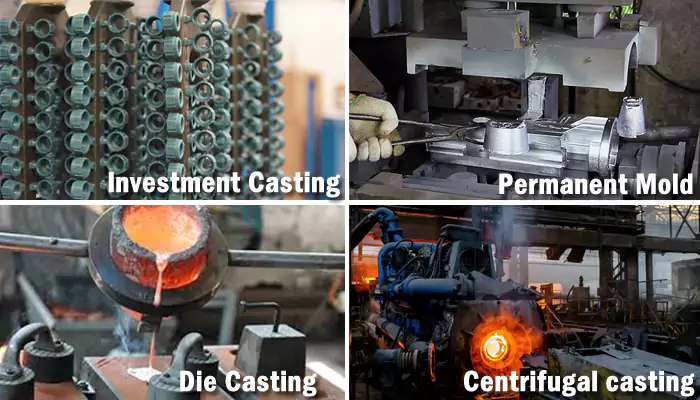

What are the common types of casting?

A supplier mentions sand casting, while another proposes investment casting. The price difference is huge. Knowing the fundamental types helps you understand why and guides the initial conversation.

The four primary industrial casting types are Sand Casting, Investment Casting, Die Casting, and Permanent Mold Casting. Each differs in mold material, production speed, precision, and ideal production volume.

You don't need the "best" process; you need the right one. Here is a quick-reference table to establish the basic framework.

| Process | Mold Material | Ideal Volume | Key Advantage | Typical Use Case |

|---|---|---|---|---|

| Sand Casting | Sand & Binder | Prototype to Medium | Maximum flexibility & size | Engine blocks, pump housings, large frames |

| Investment Casting | Ceramic Shell | Low to High | Best precision & complexity | Turbine blades, medical implants, armament |

| Die Casting | Steel Die | Very High | Extreme speed & consistency | Automotive housings, electronics, tools |

| Permanent Mold3 | Reusable Metal Mold | Medium to High | Good strength & finish | Wheels, cookware, automotive parts |

In short: choose Sand Casting for one-offs or massive parts. Choose Investment Casting for high complexity and precision in any volume. Choose Die Casting for hundreds of thousands of non-ferrous parts. Choose Permanent Mold for a strong balance of quality and output rate. This knowledge transforms your dialogue with suppliers from general inquiry to technical discussion.

What are the common casting materials?

The process is chosen. Now, do you pick aluminum, stainless steel, or something else? This choice dictates the part's performance, longevity, and often, its final cost.

Common casting materials include aluminum alloys, zinc alloys, cast iron, cast steel, stainless steels, copper alloys, and superalloys. Selection is a balance of strength, weight, corrosion resistance, heat tolerance, and cost.

The material is the soul of the component. Here’s what you need to know:

- Aluminum Alloys (e.g., A356, 380, 7075): Lightweight with good strength and corrosion resistance. Highly castable. A356 is common for high-strength structural parts (often investment cast), while 380 is a standard for high-volume die casting.

- Zinc Alloys (e.g., Zamak): Excellent for thin walls and fine detail in die casting. Offers great dimensional stability and smooth surfaces at a lower cost than aluminum, but with lower strength.

- Cast Iron (Gray, Ductile): The backbone of heavy machinery. Inexpensive, wears well, and dampens vibration. Almost exclusively sand cast due to its high pouring temperature.

- Steel & Stainless Steel: Chosen for high strength, toughness, or corrosion resistance. Used in demanding applications like valves, pumps, and food processing equipment, typically via sand or investment casting.

- Copper Alloys (Brass, Bronze): Selected for superior conductivity, corrosion resistance (especially in marine environments), or bearing properties.

- Superalloys (e.g., Inconel)4: Used in extreme heat and stress environments like aerospace. These materials are expensive and difficult to cast, making investment casting the preferred, and often only, viable process.

How Do Materials and Processes Work Together?

Why is a turbocharger housing die-cast in aluminum, while a furnace grate is sand-cast in iron? The material’s inherent properties and the process capabilities are locked together. Ignoring this synergy is a direct path to production failure.

The material must be suitable for the process (e.g., melt temperature, fluidity), and the process must be capable of preserving the material’s required properties (e.g., strength, corrosion resistance) in the final part’s shape.

This relationship is fundamental. A perfect design in the wrong material-process combination is unmanufacturable.

Real-World Case: The High-Pressure Valve Body

We worked with a client in the energy sector on a high-pressure control valve body5.

- Requirements: The part needed to handle corrosive fluids at over 5000 psi. It required internal passages with a surface finish smooth enough to prevent clogging. The material spec was CF8M stainless steel (equivalent to 316).

- Analysis: Sand casting could make the size, but the internal surface finish would be too rough, requiring extensive and costly internal machining. Die casting cannot process stainless steel.

- Solution: We recommended investment casting. The ceramic core process could form the smooth internal passages directly. The high-integrity process minimized risks of sand inclusions or porosity, which are critical failure points under high pressure.

- Result: The investment-cast valve body met all pressure test requirements, had excellent internal surface quality, and eliminated several difficult machining operations. This case shows how the material (corrosion-resistant steel) and the critical requirement (smooth internal features) logically led to the optimal process.

What Are the Advantages and Disadvantages of Casting?

Committing to a casting design means accepting a trade-off. The benefits are substantial, but the limitations are real. A clear view of both sides sets the stage for a successful project.

The key advantage of casting is producing strong, complex metal parts as a single piece at a competitive cost. The main disadvantage is the risk of internal defects, requiring rigorous process control and inspection.

Advantages of Casting

- Unmatched Design Freedom: It can create internal cavities, undercuts, and organic shapes that are impossible to machine or forge. This allows for part consolidation and optimized performance.

- Material and Structural Integrity: A wide range of alloys can be cast. A well-made casting has a continuous grain structure, often stronger than an assembly of welded pieces.

- Cost-Effectiveness for Quantity: For suitable volumes, casting is the most economical way to make a complex metal shape. High initial tooling is amortized, leading to a low per-part cost.

- Size Versatility: It can produce items from tiny dental implants to multi-ton ship propellers.

Disadvantages and Challenges

- Inherent Defect Risks: The process can introduce flaws like porosity, inclusions, or shrinkage cavities. Robust quality control (X-ray, CT scan) is essential for critical components.

- Surface and Tolerance Limits: As-cast surfaces are rougher, and dimensional tolerances are wider than machined surfaces. Critical features often require secondary machining.

- Lead Time and NRE Costs: Developing molds and processes takes time and money. For very low volumes, this upfront investment may not be justified.

- Dependence on Foundry Skill: Success hinges on the foundry’s expertise in metallurgy, mold design, and process control. Experience directly impacts yield and quality.

For more details, please visit the complete page on the advantages and disadvantages of investment casting.

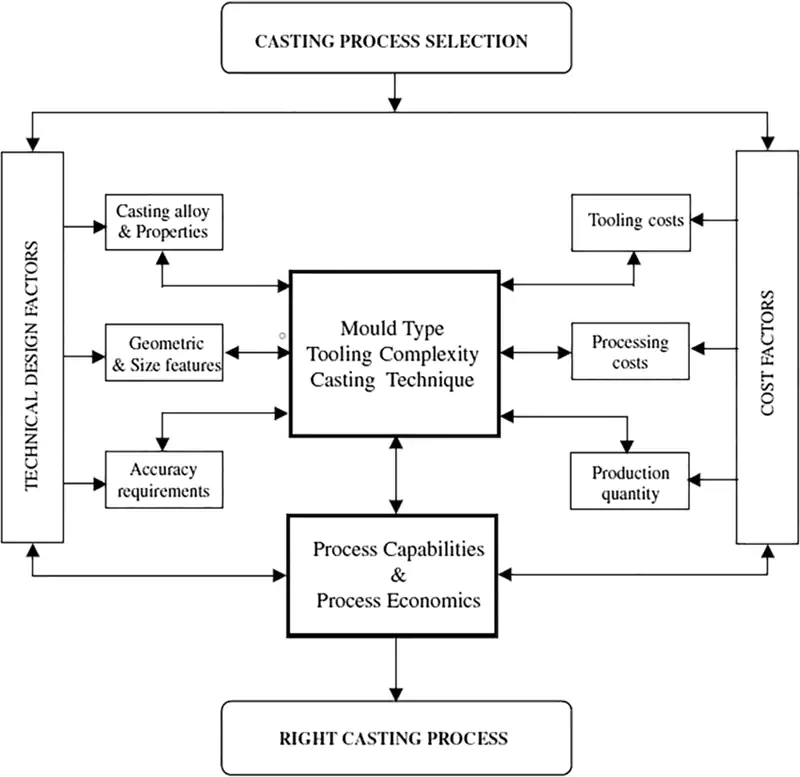

How to Choose the Optimal Casting Process?

You have a new part drawing. Where do you begin? A systematic approach prevents confusion and saves valuable time.

Start by defining three key factors: Annual Volume, Part Complexity, and Critical Tolerances. These will quickly narrow down the viable casting process options for further evaluation with a foundry.

Use this simple, three-step filter:

Step 1: Determine Your Production Volume

This is the first major filter.

- Very Low (< 100 pcs): Sand Casting (for size) or Investment Casting (for complexity). Minimizes upfront tooling cost.

- Medium (100 – 10,000 pcs): Investment Casting or Permanent Mold Casting are strong candidates.

- High (>10,000 pcs): Die Casting becomes the most economical choice for suitable materials and designs.

Step 2: Analyze Part Geometry

Can the part be ejected from a simple, two-piece mold?

- High Complexity: Choose Investment Casting.

- Moderate Complexity: Permanent Mold or Sand Casting may work.

- Simple Shape: Die Casting is highly efficient.

Step 3: Define Must-Have Tolerances & Finish

Be realistic. What does the part functionally need?

- Tight Tolerances (< ±0.2mm) / Smooth Finish: Look to Investment Casting or Die Casting.

- Standard Tolerances: Permanent Mold or Sand Casting are sufficient, with machining on critical areas.

Following this logic, you move from "We need this part cast" to "We should be speaking with investment casting specialists about this medium-volume, complex stainless steel component." This clarity makes you a more effective partner in the manufacturing process.

Conclusion

Casting turns ambitious designs into reliable, high-performance components. Understanding its processes, materials, and selection logic is key to leveraging its full potential.

-

Understanding Mold Formation is crucial for mastering casting techniques and improving product quality. ↩

-

Exploring Solidification helps you grasp its impact on casting quality and defect prevention. ↩

-

Learn about Permanent Mold casting to discover its advantages in producing high-quality automotive parts. ↩

-

Learn about the critical roles Superalloys play in extreme environments, especially in aerospace. ↩

-

Explore this link to understand the design intricacies and best practices for high-pressure control valve bodies, ensuring optimal performance. ↩