You have spent weeks designing a precise mechanical part, but the assembly fails because the surface finish causes too much friction. It is frustrating to see high-precision parts rejected simply because the surface roughness was not specified correctly.

Polishing is a finishing process that smooths a workpiece's surface by removing materials using abrasives or chemical actions. It serves two main purposes: improving functional performance—like corrosion resistance and reduced friction—and enhancing the cosmetic appearance for end-users.

Many engineers and procurement managers I talk to think polishing is just about making things look shiny. They mark "polish" on a drawing without specific parameters. In my experience at Allied Metal, this ambiguity leads to cost overruns and quality disputes. Today, I want to share the technical reality of polishing, how it differs from other finishes, and how you can control quality using international standards1.

The Role of Polishing in Precision Investment Casting

Precision investment casting, also known as lost-wax casting, is a manufacturing process capable of producing complex, net-shape metal parts with excellent dimensional accuracy and surface finish. At Allied Metal, we specialize in this process to create components for aerospace, medical, and automotive industries.

In investment casting, the as-cast surface finish typically ranges from Ra 3.2 to 6.3 µm. While this is suitable for many applications, parts requiring fluid dynamics, sealing surfaces, or cosmetic appeal often need additional polishing to achieve Ra values between 0.4 to 1.6 µm.

The investment casting process begins with a wax pattern that is coated with ceramic material to create a mold. After the wax is melted out, molten metal is poured into the cavity. The resulting cast parts have a surface that reflects the ceramic mold's texture. For applications where surface smoothness2 is critical, polishing becomes an essential secondary operation.

What makes investment casting particularly suitable for polishing is that it produces parts with minimal stock allowance. This means less material needs to be removed during polishing compared to other manufacturing methods, reducing both time and cost while preserving the part's dimensional integrity.

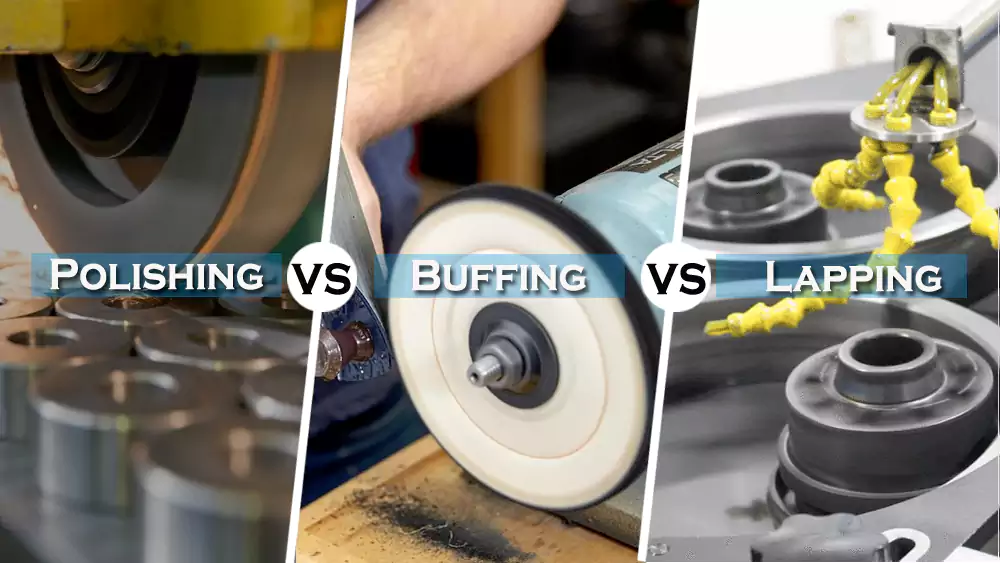

Is Polishing the Same as Buffing or Lapping?

Do you find yourself confused by the different terms used for surface finishing in manufacturing quotes? It creates a risk of ordering a process that is either too expensive or insufficient for your needs.

No, they are not the same. Polishing uses abrasives to remove scratches and material from the surface. Buffing uses a cloth wheel with a compound to create a high luster without removing much material. Lapping is a precision process used specifically to achieve extreme flatness.

Understanding the Mechanics of Material Removal

I often see drawings from Europe where the terms are used interchangeably, but the mechanical action is very different. To help you choose the right one, we need to look at what happens at the microscopic level.

Polishing is an aggressive process. We use an abrasive belt or wheel bonded with grit. It acts like a cutting tool. It cuts through the peaks of the metal surface to level it out. If you have a machined part with visible tool marks, you must polish it first. You cannot jump straight to buffing because buffing will just make the tool marks shiny, not remove them.

Buffing is the final step. Think of it as the "makeup" applied after the "surgery" of polishing. We use a soft cloth wheel (cotton or flannel) charged with a fine abrasive compound. It moves metal slightly rather than cutting it away. It creates that mirror-like reflection.

Lapping3 is pure engineering. We use a flat plate and a slurry of abrasive particles. The part floats on this slurry. We use this for seals and valves where the part must be perfectly flat to hold pressure.

Here is a quick reference table I use to train my staff:

| Process | Primary Action | Material Removal | Typical Ra (µm) | Best Application |

|---|---|---|---|---|

| Polishing | Cutting/Grinding | High | 0.4 - 1.6 | Removing tool marks, preparing for plating |

| Buffing | Burnishing | Very Low | 0.05 - 0.2 | Aesthetic mirror finish, food processing |

| Lapping | Abrading | Medium | 0.1 - 0.4 | High-precision seals, flatness requirements |

How Do We Measure Polishing Quality Using ISO Standards?

Are you worried that "smooth" means one thing to your supplier in China and another thing to your QC team in Germany? Vague specifications are the number one cause of supply chain friction.

We measure quality using the ISO 1302 standard, primarily focusing on Ra (Roughness Average) and Rz (Mean Roughness Depth). These metrics provide a quantifiable data point that ensures the surface meets the necessary engineering tolerances.

Moving Beyond "Mirror Finish"

In the early days of my career, a client asked for a "mirror finish." We polished it until it reflected light perfectly. But when they measured it with a profilometer, it failed. Why? Because the human eye is easily tricked.

For our European clients, specifically in the medical and automation sectors, we cannot rely on visual inspection alone. We must use a Stylus Profilometer4. This device drags a diamond-tipped probe across the surface to map the peaks and valleys.

Ra (Roughness Average)5 is the most common standard. It calculates the average height of the texture. For most CNC machined parts, a standard finish is Ra 3.2 µm. A good polish brings this down to Ra 0.4 µm.

However, Ra has a flaw. It is an average. It might hide a few very deep scratches that could cause a fatigue crack or corrosion point. That is why for critical parts, I recommend adding Rz. Rz measures the vertical distance from the highest peak to the lowest valley.

If you are designing a shaft that runs in a seal, Ra is important. If you are designing a cosmetic cover, visual standards (like "no visible scratches at 50cm distance") are more practical. Understanding the difference between functional roughness and cosmetic polish is key to saving money.

What Are the Cost Factors and Technical Challenges in Polishing?

Does the quote for your polished parts seem surprisingly high compared to the raw machining cost? It is painful to see a project budget explode just because of the finishing requirements.

Polishing costs are driven by material hardness, part geometry, and the required Ra level. Complex shapes with deep pockets often require manual labor, which is significantly more expensive than automated processes.

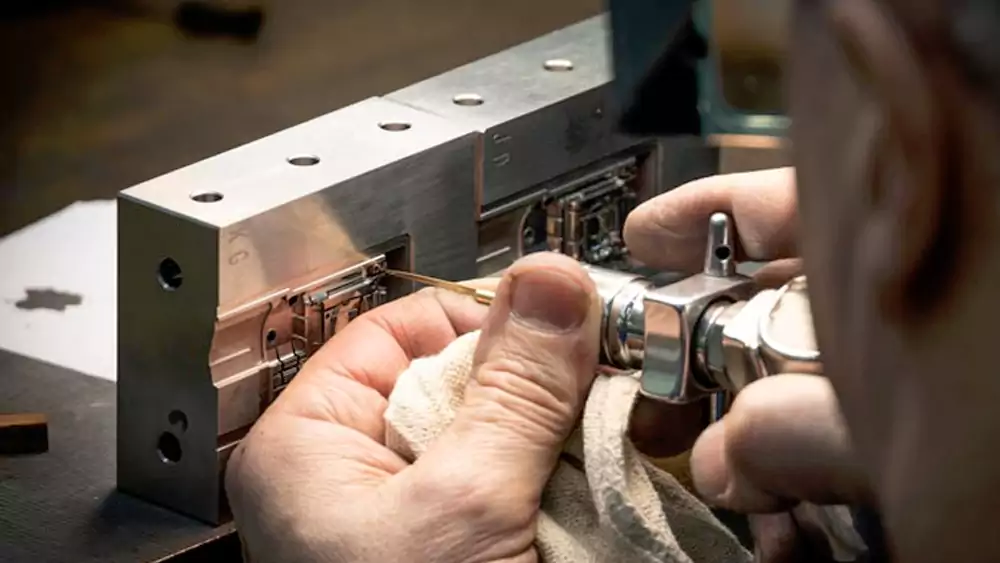

Case Study: Optimizing Costs for a Medical Housing

To give you a real-world perspective, I want to share a case from our shop floor. We had a client from Germany developing a surgical instrument housing made of Stainless Steel 316L.

The Challenge:

The initial design called for a "Ra 0.05 µm Mirror Polish" on the entire internal and external surface. The part had deep internal cavities (blind holes) that were only 10mm wide.

The Problem:

My team tried hand polishing. It was a nightmare. We could not get the polishing wheels into the deep holes. We had to use tiny Dremel tools. The labor time was huge, and the consistency was poor.

The Solution:

I proposed switching to Electropolishing for the internal areas and limiting the high mechanical polish to the external grip only.

Here is the data from our production run:

| Parameter | Original Process (Hand Polish All) | Optimized Process (Hybrid) | Improvement |

|---|---|---|---|

| Time per Part | 4.5 Hours | 1.2 Hours | 73% Faster |

| Internal Ra | 0.25 µm (Inconsistent) | 0.3 µm (Uniform) | Better Quality |

| External Ra | 0.05 µm | 0.05 µm | Same Quality |

| Cost per Part | $120 | $45 | 62% Savings |

Why this matters:

Stainless Steel 316L is tough. It "work hardens." If you polish it too aggressively with the wrong speed, the surface gets harder and harder to cut. By moving to Electropolishing (a chemical process), we removed material from the deep holes without physical stress.

When you design for polishing, remember this rule: If you can't touch it with your finger, we probably can't polish it effectively by hand. Design your radii and pockets to accommodate polishing tools if you want to keep costs down.

Conclusion

Polishing is not just about aesthetics; it is a critical engineering process defined by ISO standards and material science. By specifying clear Ra values and consulting with us early on geometry, you ensure quality and control costs. For investment cast parts, polishing transforms already precise components into finished products ready for demanding applications in medical, aerospace, and industrial sectors.

-

Exploring international standards can provide valuable insights into maintaining quality and consistency in manufacturing processes. ↩

-

Detailed Guide to Surface Finish and Roughness in Manufacturing. ↩

-

Exploring lapping will provide insights into its precision applications, especially in engineering for seals and valves. ↩

-

Explore this link to understand how a Stylus Profilometer ensures precision in surface measurement, crucial for quality control. ↩

-

Learn about Ra and its significance in surface finish standards, essential for manufacturing and engineering applications. ↩