I see many engineers struggle with long machining cycles and high material waste, especially when they deal with high-value alloys. I want to explain why near-net-shape manufacturing solves this problem and why it has become a practical choice for many projects today.

Near-net-shape manufacturing creates parts that already match most of the final dimensions, cutting down machining, reducing waste, and lowering total production cost. It is ideal for high-value metals such as titanium alloys.

I will walk through how near-net-shape works and show real applications. I will also share a case study from my own experience in the foundry industry. My goal is to help you decide when this method is best for your project.

How Near-Net-Shape Manufacturing Works?

I often meet customers who want tight tolerances but hate the cost of heavy machining. They usually do not realize how much waste comes from starting with oversized stock.

Near-net-shape works by producing a part very close to its final geometry so only minimal machining is needed for precision surfaces.

When I started in a casting shop, I learned how much geometry could be formed directly by the mold. A near-net-shape part may require a few finishing cuts for holes or sealing surfaces, but the main shape is already formed in the initial process. This creates a stable workflow because cycle times become consistent, and material use becomes predictable.

Key Points Behind the Process

- The mold or forming tool creates most of the final geometry.

- Machining is limited to critical areas only.

- The process reduces scrap, especially in titanium, nickel alloys, and tool steels.

- It improves repeatability because geometry is controlled from the start.

This flow helps teams plan more accurately and avoid unexpected machining delays.

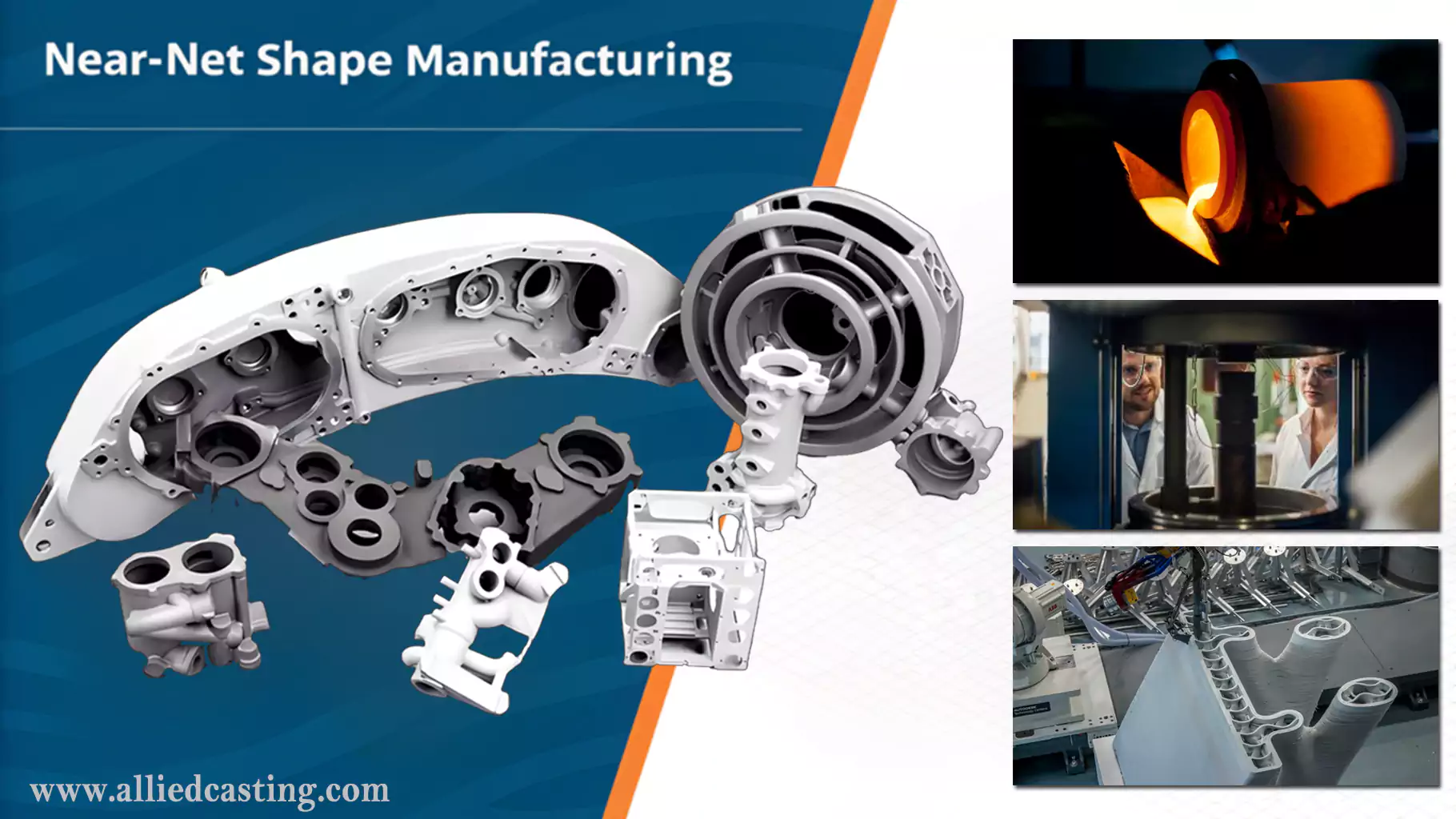

Common Near-Net-Shape Manufacturing Processes?

Most sourcing managers ask me about the actual processes behind near-net-shape. They want to know which one fits their part.

Common near-net-shape processes include investment casting, sand casting, injection molding, powder metallurgy, and metal additive manufacturing.

Below is a deeper breakdown of the major processes I use when helping customers choose the right method.

Investment Casting

Investment casting forms extremely detailed shapes. It handles complex vanes, thin-walled parts, and tight tolerances. It works well for stainless steel, tool steel, nickel alloys, and titanium alloys.

Sand Casting

Sand casting is used when the part is large or the tolerance is moderate. It is cost-effective for aluminum, iron, and steel parts.

Powder Metallurgy

Powder metallurgy1 creates dense components with controlled porosity. It is used for gears, bushings, and structural components.

Metal Injection Molding (MIM)

Metal Injection Molding (MIM)2 makes small, complex stainless steel parts with excellent repeatability.

Additive Manufacturing (AM)

AM3 builds the shape layer by layer. It is ideal for titanium brackets, medical implants, and lattice structures.

| Process Type | Best Material Range | Shape Complexity | Typical Accuracy | Part Size Range |

|---|---|---|---|---|

| Investment Casting | Steel, Inconel, Titanium | High | High | Small–Medium |

| Sand Casting | Aluminum, Iron, Steel | Medium | Medium | Medium–Large |

| MIM | Stainless Steel | High | High | Small |

| Powder Metallurgy | Steel, Copper Alloys | Medium | Medium | Small–Medium |

| Additive Manufacturing | Titanium, Aluminum, Maraging | Very High | High | Small–Medium |

Materials Used in Near-Net-Shape Manufacturing?

Material choice is always a concern for buyers because not all metals form well near-net-shape.

Near-net-shape manufacturing works with a wide range of metals including aluminum, steel, stainless steel, titanium alloys, nickel alloys, and copper alloys.

In my work with aerospace suppliers, titanium alloy parts became a major focus because machining titanium is slow, expensive, and tool-intensive. When I switched a customer’s workflow from billet machining to investment casting, we saved more than 60% of raw material cost.

Material Suitability Breakdown

Aluminum Alloys

Good for lightweight designs, automotive housings, and large castings.

Stainless Steel

Works for pumps, valves, and aerospace brackets where corrosion resistance is key.

Titanium Alloys

Common for aircraft structures and medical devices. Near-net-shape offers major cost savings.

Nickel Alloys

Used for turbines and heat-resistant components. Near-net-shape helps reduce tool wear.

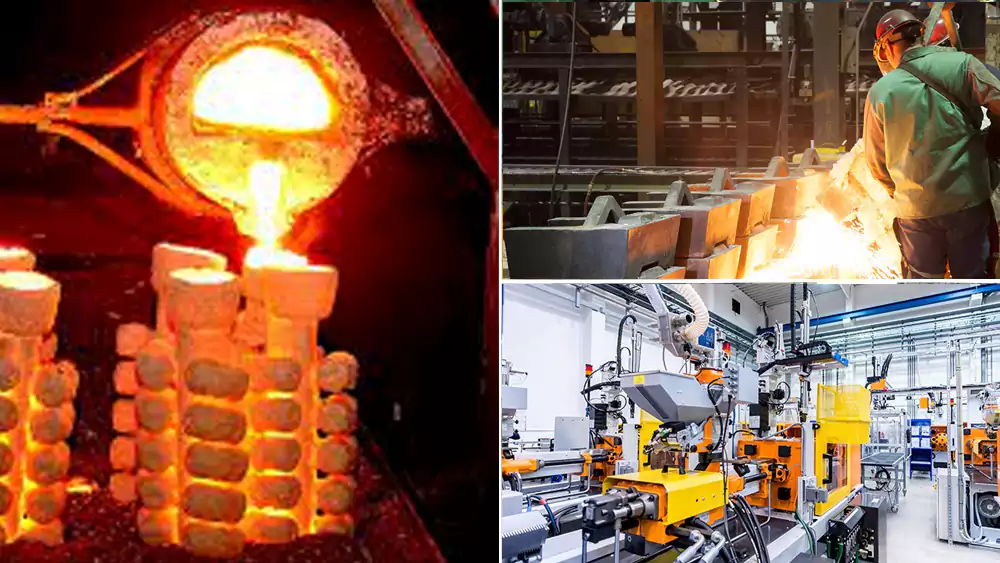

Examples and Industrial Applications?

Many engineers understand the theory, but they need to see real-world performance before choosing a process.

Near-net-shape is used in aerospace, energy, automotive, medical devices, robotics, and industrial machinery.

Below is a detailed case study from my own foundry experience that shows how near-net-shape delivers measurable value.

Case Study: Titanium Aerospace Support Bracket (Investment Casting Near-Net-Shape)

I once worked with a senior casting technician who had more than 20 years of hands-on experience with titanium alloys. He helped develop a near-net-shape solution for a customer who machined brackets from solid titanium billets. The waste was extreme, and the cycle time was long.

We switched the part to investment casting near-net-shape. The results were dramatic.

Part Requirements

| Parameter | Specification |

|---|---|

| Material | Ti-6Al-4V4 |

| Final Weight | 0.82 kg |

| Original Billet Weight | 2.70 kg |

| Casting Weight | 1.05 kg |

| Machining Allowance | 0.5–0.8 mm |

| Key Surfaces | Two bores, one mounting face |

| Tolerance Goal | ±0.15 mm after machining |

Measured Results

| Category | Before (Billet Machining) | After (Near-Net-Shape Casting) |

|---|---|---|

| Material Waste | 1.88 kg | 0.23 kg |

| Material Waste Reduction | — | 87.8% reduction |

| Total Machining Time | 212 minutes | 54 minutes |

| Machining Time Reduction | — | 74.5% reduction |

| Cost Reduction | — | 58% lower unit cost |

The technician told me, “Titanium is too valuable to cut away. Near-net-shape is the only way to stay competitive.”

His words stayed with me. He was right.

Advantages of Near-Net-Shape Manufacturing?

Engineers often need to justify switching processes to management. They want clear benefits.

Near-net-shape lowers cost, reduces machining, cuts material waste, shortens lead time, and offers stable repeatability.

Major Benefits

Reduced Machining

Most geometry is formed in the first step.

Less Material Waste

This is critical for titanium, Inconel, and stainless steel.

Consistent Quality

Dimensional control improves because the shape comes directly from the tooling.

Faster Lead Times

Machining becomes predictable and stable.

Near-Net-Shape vs. Net-Shape: What’s the Difference?

Many people confuse near-net-shape with full net-shape. This often creates unrealistic expectations.

Near-net-shape delivers most of the final geometry, while net-shape aims for zero machining but is harder to achieve in real production.

Key Differences

Near-Net-Shape

- Small machining allowance

- Easier to achieve in casting and AM

- Good balance of cost and precision

Net-Shape

- Almost no machining

- Only possible for simple geometries

- Often expensive for high-tolerance parts

Engineers usually choose near-net-shape because they need both accuracy and cost control.

When to Choose Near-Net-Shape for Your Project?

Customers usually ask me when near-net-shape is the best option instead of full machining.

Choose near-net-shape when you use high-value metals, need complex geometry, or want to reduce machining and waste.

Best Situations

High Material Cost (e.g., Titanium, Inconel)

You save the most money here.

Complex Shapes

Casting or AM can form features that machining struggles with.

High Volume or Stable Repeat Production

Tooling becomes cost-effective.

Long Machining Cycles

Near-net-shape shortens lead time and frees machine capacity.

Conclusion

Near-net-shape manufacturing helps lower waste, cut machining time, and improve stability. It gives you a practical way to control cost and still achieve high precision in complex metal parts.

-

Explore this link to understand how Powder Metallurgy enhances component density and porosity control, crucial for various applications. ↩

-

Discover insights on MIM's ability to produce complex parts with high repeatability, making it a game-changer in manufacturing. ↩

-

Explore the Comprehensive Guide to Additive Manufacturing (AM). ↩

-

Learn more about Ti-6Al-4V to see why it's a preferred choice in aerospace and medical applications due to its strength and corrosion resistance. ↩