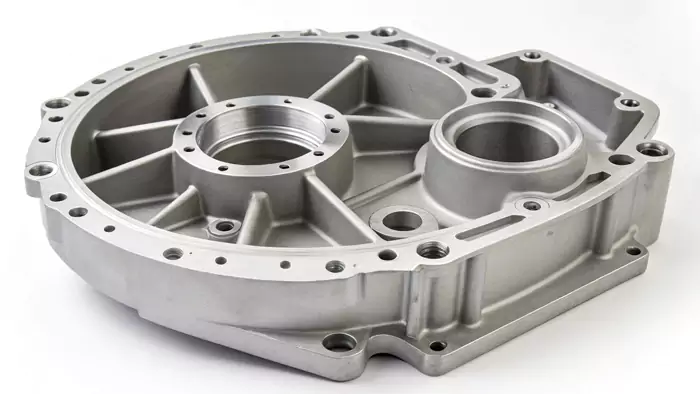

Struggling with intricate aluminum part designs? Traditional methods might not deliver the needed precision. Aluminum investment casting offers a reliable path to high-quality, complex components for your projects.

Aluminum investment casting is an excellent solution for complex metal parts. It offers precision, smooth finishes, and design freedom. This method is especially good for lightweight and strong components.

I've seen firsthand how this process can transform a challenging design into a reality. It’s a fascinating journey from a concept to a solid metal part, and I believe understanding it can greatly benefit your sourcing decisions. But before we dive deep into aluminum specifics, let's make sure we are all on the same page about what investment casting truly means. It’s a technique with a long history, refined over centuries to meet today's demanding standards.

What Exactly Is Investment Casting?

Confused by casting terms? Need a clear, simple definition? Investment casting is an old technique, but it has been perfected for modern, high-precision manufacturing needs.

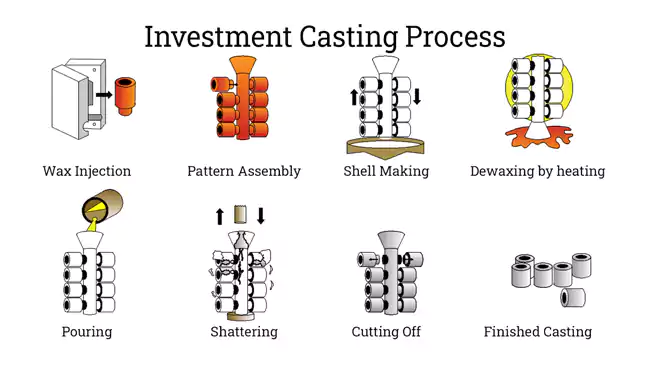

Investment casting, also known as "lost-wax casting," creates detailed metal parts. It uses a wax pattern to form a ceramic mold. This method produces intricate shapes with excellent surface finishes, earning its "precision casting" name.

Investment casting is a manufacturing process that I've grown to respect deeply over my years in the industry. It starts with creating a pattern of the desired part, usually from wax. This wax pattern is an exact replica of the final product. Several of these patterns can be attached to a central wax stick, called a sprue, to form a tree-like assembly. This "tree" is then dipped into a ceramic slurry1 and coated with sand-like stucco material. This step is repeated multiple times. Each coat builds up the shell thickness and strength. Once the ceramic shell has dried and hardened, the wax inside is melted out. This is why it's often called the "lost-wax" process. The hollow ceramic shell that remains is the mold. This mold is then fired to give it strength. Molten metal, in our case aluminum, is poured into this pre-heated ceramic mold. After the metal cools and solidifies, the ceramic shell is broken away. The individual parts are then cut from the sprue, cleaned, and finished. It’s called precision casting because it can produce parts with very fine detail and tight dimensional tolerances, often reducing the need for further machining.

Is Aluminum a Suitable Material for Investment Casting?

Wondering if aluminum is a good fit for investment casting? Its unique properties might surprise you. Let's explore the benefits aluminum brings to this precise manufacturing process.

Absolutely, aluminum is highly suitable for investment casting. Its fluidity allows it to fill complex molds. Its light weight, corrosion resistance, and good mechanical properties make it an excellent choice for many detailed parts.

In my experience, aluminum is a fantastic material for investment casting, especially for parts where weight and intricate design are key. Sourcing managers like Michael, who deal with aerospace or energy sector components, often find aluminum's properties very beneficial. One of the main reasons aluminum works so well is its excellent fluidity when molten. This means it can flow into very thin sections and complex cavities within the ceramic mold, capturing fine details accurately. Another big plus is its high strength-to-weight ratio. You get strong parts without adding unnecessary bulk, which is critical in industries like aerospace. Aluminum also naturally forms a protective oxide layer, giving it good corrosion resistance. This can save on additional protective coatings later. Beyond these, aluminum offers good thermal and electrical conductivity, and it's relatively easy to machine if any secondary operations are needed. We often use alloys like A356 for its good casting characteristics and mechanical properties. Of course, like any process, there are things to watch, such as controlling gas porosity and managing solidification shrinkage, but with proper foundry practices, these are well managed. The result is high-quality, precise aluminum components.

How Does Aluminum Investment Casting Compare to Sand and Die Casting Methods?

Choosing the right casting method for aluminum is crucial for your project's success. Overwhelmed by the options? Let's compare key methods to help clarify your decision-making process.

Aluminum investment casting excels in producing complex parts with superior surface finish and tight tolerances compared to sand casting. It also offers more design freedom for intricate geometries than die casting.

When I talk to sourcing managers like Michael, we often discuss which aluminum casting method is best for their specific needs. Sand casting, die casting, and investment casting each have their place. Sand casting is generally used for larger parts and is more cost-effective for lower volume or very big components where surface finish and tight tolerances are less critical. The molds are made from sand, so the surface is rougher. Die casting, on the other hand, uses reusable metal molds (dies) and is great for high-volume production of parts with good dimensional accuracy. However, the tooling costs for die casting are high, and it's less suited for very complex internal features or undercuts compared to investment casting.

Investment casting really shines when you need:

- High complexity: It can produce intricate shapes, thin walls, and internal passages.

- Excellent surface finish: Typically, much smoother than sand casting, reducing finishing costs.

- Tight tolerances: Achieves near-net-shape parts, minimizing machining.

Here's a simple comparison:

| Feature | Sand Casting | Die Casting | Investment Casting |

|---|---|---|---|

| Complexity | Low to Medium | Medium to High | Very High |

| Surface Finish | Rough | Good to Excellent | Excellent |

| Tolerances | Loose | Tight | Very Tight |

| Tooling Cost | Low | Very High | Medium to High |

| Production Volume | Low to High | High | Low to Medium (can be high) |

| Part Size | Medium to Very Large | Small to Medium | Small to Medium |

So, for a project needing small to medium-sized aluminum parts with intricate designs and a smooth finish, investment casting is often the most effective choice, even if the tooling cost is a bit higher than sand casting.

Why Choose Aluminum Investment Casting?

Need intricate aluminum parts with flawless surfaces? Are traditional methods falling short? Investment casting for aluminum offers unmatched design freedom and excellent finish quality.

Aluminum investment casting allows for highly complex, near-net-shape parts. These can have thin walls and fine details. It achieves excellent surface finishes, typically 63-125 microinches RMS, directly from the mold.

The magic of aluminum investment casting for complex shapes lies in how the mold is made. Because we start with a wax pattern, which can be injection molded into very complex forms or even 3D printed, the design possibilities are vast. We can create intricate internal cavities, undercuts, and fine details that would be difficult or impossible with other methods like die casting or machining from a solid block. Once this detailed wax pattern is coated in ceramic and the wax is melted out, the resulting ceramic mold is a perfect negative of the part. When the molten aluminum fills this mold, it captures every detail. This ability to create "near-net-shape" parts is a huge advantage. It means the part comes out of the mold very close to its final dimensions. This significantly reduces or even eliminates the need for costly and time-consuming secondary machining operations. For a Sourcing Manager like Michael, this translates to faster lead times for finished parts and lower overall costs, especially when material waste from machining is considered. The surface finish is another key benefit. The ceramic shell molds2 have a very smooth internal surface, which imparts an excellent finish to the cast aluminum part, often in the range of 1.5 to 3.2 micrometers Ra (63 to 125 microinches RMS). This smooth finish is often suitable for use as-is, or it requires minimal polishing.

What are the different types of aluminum casting?

Exploring different ways to make metal parts? Unsure if casting is the best route? Let’s look at how investment casting uniquely differs from other common metal fabrication techniques.

Investment casting creates complex shapes in a single step. This often reduces or eliminates the need for extensive machining, unlike subtractive methods. It also offers more intricate designs than forging can typically achieve.

When I discuss manufacturing options with clients, it's important to compare investment casting with other techniques. CNC machining, for example, is a subtractive process. It starts with a solid block of material and removes material to achieve the final shape. This is great for precision and can be used for prototypes or low volumes. However, for complex parts, machining can lead to significant material waste and long cycle times, making it expensive. Investment casting, being a near-net-shape process, minimizes waste and can be more cost-effective for complex geometries in medium volumes. Forging is another common method where metal is shaped by compressive forces. Forged parts are very strong and durable. But, forging is generally limited to simpler shapes than investment casting can produce. Creating complex internal features with forging is very challenging. Metal Injection Molding (MIM)3 is similar to investment casting in some ways but is typically better for very small, highly complex parts in very high volumes. Direct Metal Laser Sintering (DMLS) or 3D printing in metal is excellent for rapid prototyping and highly complex one-off parts, but it can be slower and more expensive for production volumes compared to investment casting.

Here's a brief overview:

| Technique | Key Advantage | Best For | Limitation for Complexity |

|---|---|---|---|

| Investment Casting | Complex shapes, good finish, near-net | Intricate parts, medium volumes | Size, initial tooling time |

| CNC Machining | High precision, flexible | Prototypes, low-medium vol, simpler shapes | Material waste, cost for very complex parts |

| Forging | High strength, good fatigue resistance | Simpler shapes needing high strength | Limited design complexity |

| Metal 3D Printing | Very complex shapes, no tooling | Prototypes, very low volume, custom parts | Speed, cost for volume |

For someone like Michael, who needs reliable production of complex aerospace parts, investment casting often hits a sweet spot by balancing complexity, cost, and material properties.

Challenges of Aluminum Investment Casting

Considering aluminum investment casting for your next project? It's important to be aware of its potential downsides. Understanding these limitations helps in making informed decisions for your critical components.

Challenges with aluminum investment casting can include higher initial tooling costs compared to sand casting. Lead times for first articles can also be longer. There are also some size limitations for parts.

While aluminum investment casting offers many benefits, I always believe in being transparent about its potential challenges. First, the initial tooling cost for creating the wax injection molds can be higher than, say, patterns for sand casting. This means it’s often more economical for medium to higher production runs where this cost can be spread over many parts. The lead time to produce the first articles can also be longer because creating the tool and perfecting the process takes time. For projects with very tight deadlines for the initial samples, this needs to be factored in. There are also practical limitations on the size and weight of parts that can be economically produced with investment casting. Very large components are usually better suited to sand casting or fabrication. Another aspect to manage carefully is the casting process itself. Aluminum alloys can be prone to issues like gas porosity or shrinkage defects if the process isn't tightly controlled. This is where foundry expertise really matters – ensuring proper gating design, melt quality, and pouring parameters. Alloy selection is also crucial; not all aluminum alloys are equally castable or provide the desired final properties. So, careful consultation on material choice is important. These are points I discuss with clients like Michael to ensure we choose the right process and set realistic expectations from the start.

Why Choose Allied Metal for Aluminum Investment Casting?

Need a reliable aluminum investment casting partner? Concerned about quality, expertise, and on-time delivery? Allied Metal offers the experience and dedication your demanding project deserves.

Partner with Allied Metal for our deep expertise in aluminum investment casting. We have a strong commitment to quality from the shop floor to delivery. We provide comprehensive support for your most challenging projects.

My journey in this industry began on the shop floor of a casting facility. That hands-on experience taught me the deep complexities and incredible potential of metal casting. It’s why I founded Allied Metal – to deliver high-precision investment casting solutions, focusing on quality and innovation. When you partner with us for your aluminum investment casting needs, you're not just getting a supplier; you're getting a team that understands the challenges faced by Sourcing and Quality Managers like Michael. We know that for aerospace and energy sectors, precision, material integrity, and documentation are non-negotiable. We've built our processes to meet these exacting standards. At Allied Metal, we also offer 3D printing and rapid prototyping services. This means we can help you iterate designs quickly, produce prototypes for validation, and then seamlessly transition to investment casting for production, often using 3D printed patterns for initial runs to save on hard tooling costs for early-stage projects. I am personally committed to sharing my experience to help customers bring their challenging projects to life. We thrive on solving complex manufacturing problems and are dedicated to ensuring your components are delivered to specification and on time. We believe in transparent communication and a collaborative approach, making us a reliable extension of your team.

Conclusion

Aluminum investment casting offers precise, complex, and lightweight parts, ideal for many industries. For your demanding projects, our expertise and dedication at Allied Metal ensure quality and successful outcomes.

-

Learn about the role of ceramic slurry in investment casting, crucial for creating strong molds that enhance the quality of cast parts. ↩

-

Discover how ceramic shell molds contribute to superior casting quality and surface finish, making them essential in modern manufacturing. ↩

-

Discover how MIM can be advantageous for small, complex parts and how it compares to other methods. ↩