Struggling with defects in high-strength steel castings? Choosing an advanced alloy can solve a design problem but create a manufacturing nightmare, leading to costly failures and delays.

The most challenging steels to cast are high-alloy grades like tool steels and superalloys. Their complex chemistry creates issues like poor molten metal flow, high shrinkage, and a tendency to crack, demanding expert process control.

If you are planning to source precision components like turbine blades or medical implants, the choice of steel will define both performance and service life. After more than two decades on the foundry floor, I’ve learned that steel has its own personality—some grades boast great strength yet crack during cooling, while others resist heat but destroy tooling in the process. For sourcing managers, the real question is never just “Can we cast this?” but “Can we cast it perfectly, on time, and on budget?” The greatest challenge lies not in any single steel grade, but in how my team and I integrate process, equipment, and expertise to overcome casting defects and transform these challenging materials into reliable parts our customers can depend on.

What are the "Easy" Steels for Casting?

Before we tackle the difficult alloys, what are the reliable workhorses? What makes a steel straightforward to cast?

The easiest steels to cast are low-carbon and low-alloy grades. Their simple chemistries give them predictable behavior, good molten flow, and excellent reliability for a wide range of parts.

Common steels in casting

At my foundry, “simple” means predictable. The most common steels are popular because they strike an excellent balance between performance, castability, and cost. For most purchasing managers, these are the preferred materials for countless industrial components that need to be reliable without breaking the bank.

These reliable steels generally fall into two groups:

- Low-Carbon Steels (e.g., 1020): These are the true workhorses. Their low carbon content means they aren't incredibly strong on their own, but they are tough and very forgiving in the casting process. Their main advantage is excellent fluidity1—the molten metal flows like water into every detail of the mold. They also have a low, predictable shrinkage rate2, which simplifies tooling design and prevents defects.

- Low-Alloy Steels (e.g., 8620): These are a step up. We add small amounts of elements like nickel and chromium to improve strength. They still cast very well but offer much better performance. The real benefit is that they are designed to be heat-treated after casting. This allows us to create a part that is easy to cast and then transform it into a hard, wear-resistant final component.

What Are the Top 10 Most Difficult Steels to Cast?

So, which alloys consistently give foundries a headache? What are the specific steels that require the highest level of expertise to cast successfully?

The most difficult steels are high-alloy grades that challenge the laws of physics. They include manganese steels, tool steels, and superalloys, notorious for extreme shrinkage, poor flow, and cracking.

Challenges and Solutions in Difficult-to-Cast Steel

In my experience, a steel's "difficulty" is a mix of its behavior in the furnace and its attitude during cooling. When a client like Michael specifies one of these materials, it's a signal that we need to apply our most advanced process controls. This table breaks down not just the problems, but more importantly, how we solve them.

| Steel Type | Grade Example | Why It's Difficult | How We Solve It |

|---|---|---|---|

| 1. Hadfield Steel | Austenitic Manganese Steel | Extreme Shrinkage & Work Hardening: This steel shrinks aggressively during cooling, causing cracks. It also becomes incredibly hard the moment you try to machine it. | We design specialized gating and risers to feed the casting as it shrinks. All finishing is done by grinding, not cutting, to manage the extreme work-hardening. |

| 2. High-Speed Tool Steel3 | M2, M42 | Poor Fluidity & Cracking: The high tungsten content makes the molten metal thick and sluggish. It's prone to cracking during the post-casting quench hardening. | Vacuum-assist casting is essential to pull the metal into fine details. We use a precisely controlled, multi-stage heat treatment with interrupted quenching to prevent cracks. |

| 3. Air-Hardening Tool Steel | A2, D2 | Distortion & Decarburization: These steels can warp easily in complex shapes as they cool. The surface can lose carbon, making it soft. | We design the casting tree with robust supports to prevent distortion. The entire process is done in a vacuum furnace to prevent surface decarburization. |

| 4. High-Carbon Stainless | 440C | Brittleness & Poor Fluidity: The high carbon and chromium needed for hardness make it brittle and thick when molten, making thin sections difficult to cast. | We use higher pouring temperatures and insulated molds to keep the metal fluid longer. A post-cast annealing cycle is required to restore toughness before shipment. |

| 5. Martensitic Stainless | 17-4 PH | Complex Heat Treatment: Achieving the final properties requires a very precise, multi-stage heat treatment. Any deviation results in a failed part. | Our in-house heat treatment facility uses calibrated furnaces and software control to execute the multi-stage solution annealing and aging process perfectly every time. |

| 6. Nickel-Based Superalloys | Inconel 718 | High Pouring Temperature & Reactivity: Not a steel, but a common challenge. Melts at very high temps and can react with the ceramic mold, causing surface defects. | We use specialized zirconia-based ceramic shells that can withstand the heat. The entire process is performed in a high-vacuum environment to prevent reaction with air. |

| 7. Cobalt-Based Superalloys | Stellite 6 | Very Poor Fluidity & Machinability: These are like casting molten peanut butter. They are incredibly difficult to get to fill the mold and are a nightmare to machine afterward. | We use pressurized casting systems to force the metal into the mold. For machining, we rely on specialized ceramic cutting tools and very rigid 5-axis machines. |

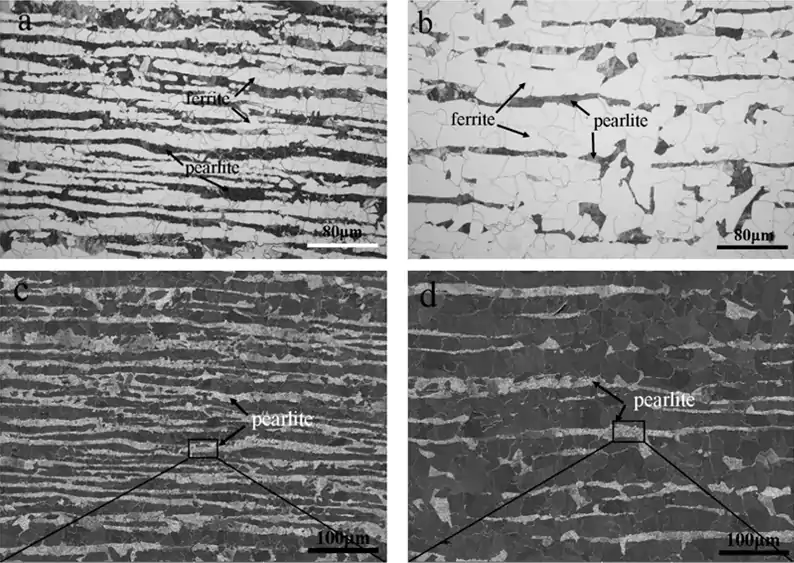

| 8. Duplex Stainless Steel | 2205 | Precise Cooling Control: These steels need a perfect 50/50 balance of two crystal structures (ferrite and austenite). This balance is entirely dependent on the cooling rate. | We control the shell temperature and use insulating blankets to manage the cooling rate precisely, ensuring the correct microstructure and properties are achieved. |

| 9. High-Chromium White Iron | ASTM A532 | Extreme Brittleness & Abrasiveness: An incredibly wear-resistant material that is as brittle as glass. It's also extremely abrasive on all tooling. | The mold design is simplified to avoid any stress concentrations. All finishing is done with diamond grinding wheels, as conventional tools cannot cut it. |

| 10. Hadfield Steel | Austenitic Manganese Steel | Extreme Shrinkage & Work Hardening: This steel is famous for its toughness, but it has a very high shrinkage rate during cooling, which can cause severe cracking. It also work-hardens instantly, making any secondary machining extremely difficult. | We design the casting with a specialized, oversized gating and riser system to feed the part's extreme shrinkage and prevent hot tears during solidification. Post-casting, conventional machining is strictly avoided; all finishing and final dimensioning are performed with heavy-duty grinding, as the material's work-hardening properties would destroy standard cutting tools. |

What Is the "Hardest" Steel to Cast?

If you had to pick one, what is the single most difficult steel to get right? What is the ultimate challenge that tests a foundry's limits?

While many are contenders, high-alloy tool steels are arguably the "hardest" to cast perfectly. Their chemistry is a balancing act on a knife's edge, making them highly prone to invisible internal defects.

Diving Deeper into the Ultimate Challenge

When a client like Michael asks me this, I explain that "hardest" has multiple meanings. But from a pure process control perspective, the high-alloy tool steels (like D2 or M2)4 represent the peak of casting difficulty.

Here’s why they are our ultimate test:

- Carbide Segregation5: These steels are full of heavy alloying elements like chromium and tungsten. As the casting cools, these heavy elements can clump together, forming hard, brittle spots called carbides. This defect, known as segregation, can be invisible on the surface but will cause the tool or die to fail catastrophically in service. Preventing it requires absolute control over the cooling rate.

- Micro-Porosity: Because the molten metal is so thick and sluggish, tiny gas bubbles can get trapped during solidification. This creates microscopic pores inside the part. For a high-pressure mold or a cutting tool, this is unacceptable. We use a combination of vacuum casting and Hot Isostatic Pressing (HIP) after casting to eliminate this. HIP is a process that uses high pressure and heat to squeeze the casting and weld these internal voids shut.

Successfully casting these materials requires technology and experience working in perfect harmony.

What's the Most Challenging Material You've Personally Worked With?

Casting is only half the battle. Many of these difficult-to-cast steels are also notoriously challenging to machine, adding another layer of complexity to part production.

One of the most challenging projects my team ever handled was a set of investment cast turbine blades made from a single-crystal nickel-based superalloy. It's not a steel, but it's the next level of difficulty.

Diving Deeper into a Challenging Project

I'll never forget a project for an aerospace client. They needed turbine blades cast from a single-crystal (SX) superalloy. This means the entire part has to be one continuous metal crystal, with no grain boundaries to weaken it.

The casting process was incredibly delicate. We had to withdraw the ceramic shell from the furnace at a precise, incredibly slow rate—just a few millimeters per hour—to allow the single crystal structure to "grow" along the length of the blade.

But the real challenge came afterward. The root of the blade needed to be machined to fit into the engine disk. Machining a single-crystal superalloy is a nightmare.

- It has no grain boundaries, which makes it incredibly tough and "gummy."

- It work-hardens instantly. The material becomes harder the moment a tool touches it.

- It generates extreme heat. The material is a poor thermal conductor, so all the cutting energy turns into heat right at the tool tip, destroying expensive carbide tools in seconds.

We had to use our most rigid 5-axis CNC machine and specialized ceramic cutting tools. We spent weeks developing the perfect tool paths and using high-pressure coolant to keep the tools from failing. It was a slow, painstaking process, but the final parts were perfect. It's a reminder that sometimes, the biggest challenge isn't just casting the part, but finishing it.

Which Metal Is Hardest: Iron, Steel, Tungsten, or Copper?

Among these common metals, which one is fundamentally the hardest? How do they stack up in a direct comparison?

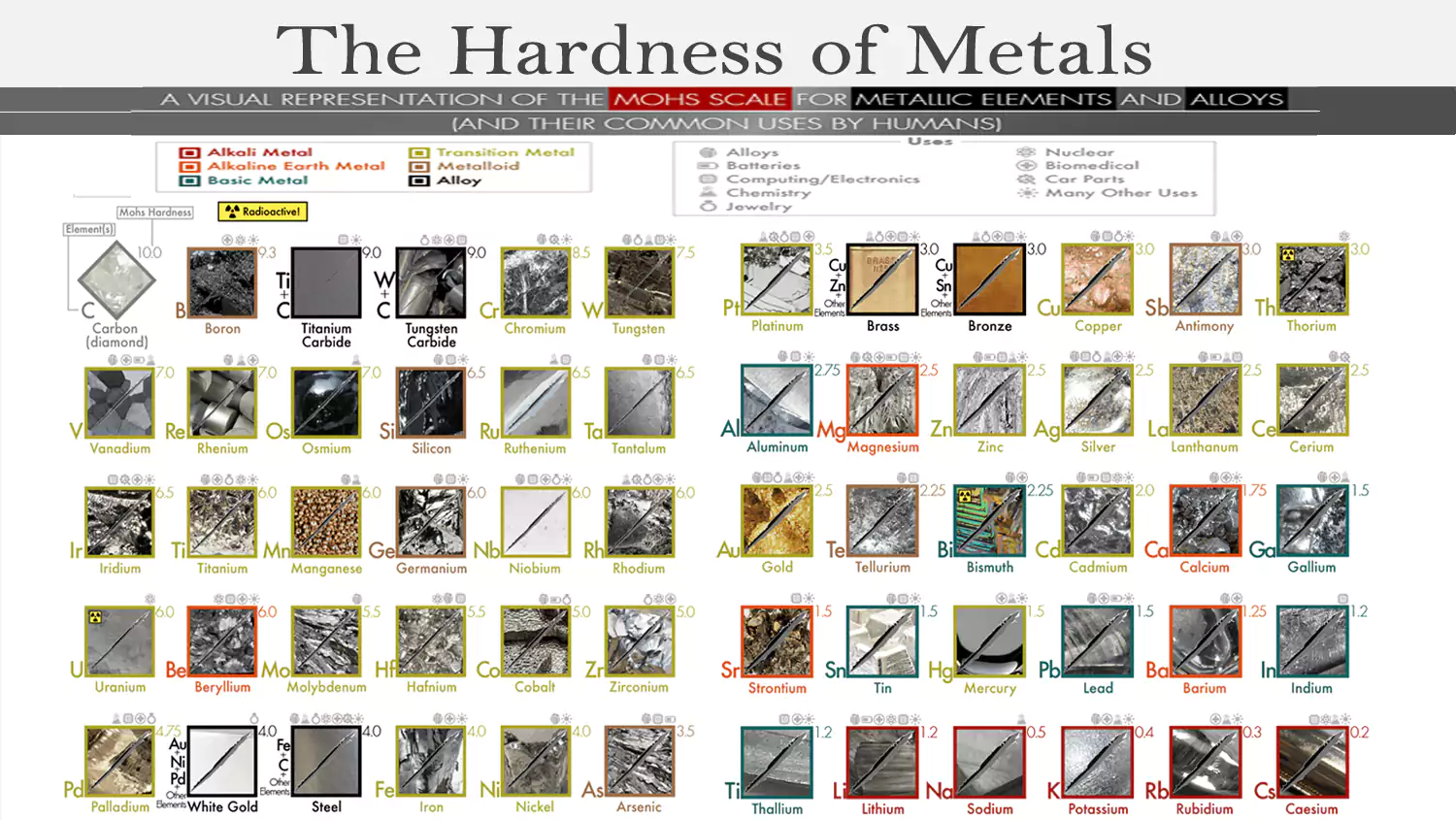

Of these four, tungsten is the hardest pure metal. However, steel is an alloy that can be heat-treated to become much harder than iron, copper, or even pure tungsten.

Diving Deeper into Hardness Comparison

Hardness is a material's ability to resist scratching or indentation. For an engineer, it's a fundamental property. Here's how these four common metals compare.

| Metal | Type | Mohs Hardness (Approx.) | Key Characteristics |

|---|---|---|---|

| Copper | Pure Element | 3 | Very soft and ductile. Excellent electrical conductor. Easily scratched. |

| Iron | Pure Element | 4 | Harder than copper, but still relatively soft. It's the primary ingredient in steel. |

| Steel | Alloy | 4 - 8.5 | An alloy of iron and carbon. Its hardness varies enormously. A simple, low-carbon steel is soft, but a heat-treated tool steel can be extremely hard, capable of scratching glass and quartz easily. |

| Tungsten | Pure Element | 7.5 | A very hard and dense pure metal with the highest melting point. It is harder than most pure metals and all but the most specialized steels. |

The Verdict:

- In their pure forms, tungsten is the hardest on this list.

- However, the true champion of hardness is steel, because we can engineer it. Through alloying and heat treatment, we can create tool steels that are significantly harder than pure tungsten.

- The material we use to make our cutting tools, Tungsten Carbide, is a ceramic compound of tungsten and carbon. With a Mohs hardness of 9, it's one of the hardest materials on earth.

Conclusion

Difficult-to-cast steels present immense challenges, but they are not impossible. With expert process control and deep experience, even the most stubborn alloys can be transformed into flawless, high-performance components.

-

Understanding fluidity is crucial for optimizing the casting process and ensuring high-quality components. ↩

-

Exploring shrinkage rate helps in designing better molds and reducing defects in cast components. ↩

-

Explaining the properties, categories, grades, and applications of tool steel, and how to select the appropriate tool steel for your project. ↩

-

Explore this link to understand the unique properties and applications of high-alloy tool steels, crucial for advanced manufacturing. ↩

-

Learn about carbide segregation and its impact on tool performance, essential for anyone involved in metallurgy or manufacturing. ↩