Material Selection Guide for Machining

Choosing the right material is the first step to a successful product. Explore our extensive range of machinable metals and plastics, backed by decades of manufacturing expertise.。

- 100+ Machinable Materials

- Prototype to Production

- Free DFM Consultation

Quick Material Selection Guide

Follow these simple steps to choose the right material for your machining project

1

Identify the primary function, operating environment, and performance requirements of your part.

2

Determine needed strength, hardness, wear resistance, and temperature tolerance.

3

Assess exposure to chemicals, moisture, UV radiation, and other environmental conditions.

4

Consider machinability, required tolerances, and compatibility with finishing processes.

5

Balance performance requirements with budget constraints and project timeline.

Select the appropriate material based on the critical performance requirements and manufacturing considerations for your custom parts. Refer to the following examples:

Tool steels, titanium alloys, high-strength aluminum Ideal for structural components, aerospace parts, and high-stress mechanical assemblies requiring superior mechanical properties.

Tool steels, titanium alloys, high-strength aluminum Stainless steels, titanium, specialty alloys Perfect for marine, chemical, and medical applications where environmental resistance is critical.

Titanium, aluminum, magnesium alloys, and carbon fiber composites are ideal for weight-sensitive applications such as automotive, aerospace, and portable devices.

Inconel alloys, Hastelloy alloys, ceramics, and similar materials are suitable for engine components, furnace components, and high-temperature industrial equipment.

Carbon steel, standard aluminum, and engineering plastics are most suitable for high-volume production, prototyping, and applications where cost optimization is paramount.

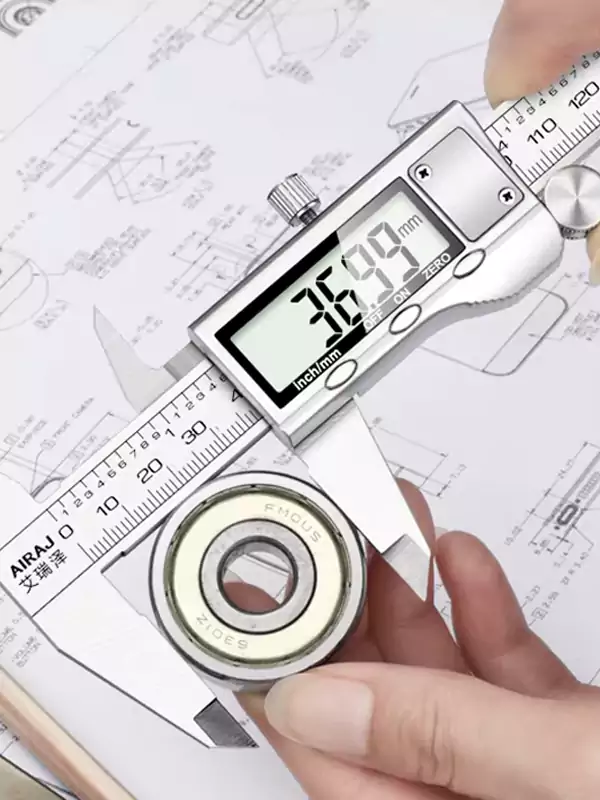

Tool steel and precision grinding materials are essential for medical devices, measuring instruments, precision tools, and high-precision mechanical components.

Material Categories

Explore our comprehensive range of materials optimized for CNC machining and investment casting applications.

Composite Materials:

This list covers only some of the materials we handle. If you need others, please contact us for more details.

Your Partner in Precision & Reliability

For small and medium-sized enterprises and brand owners, a reliable supply chain is crucial. As your dedicated manufacturing partner, Allied Metal ensures every delivered part meets specifications and arrives on time.

Our 3, 4, and 5-axis machining equipment and precision casting facilities can handle any complex machining requirement. Advanced coordinate measuring machines and material testing laboratories ensure quality assurance. We provide the stable support your brand needs to grow.

Ready to Start Your Project?

Our engineers are ready to provide a free DFM analysis and a competitive quote for your custom parts. Leverage our expertise to choose the perfect material and optimize your design for manufacturing.