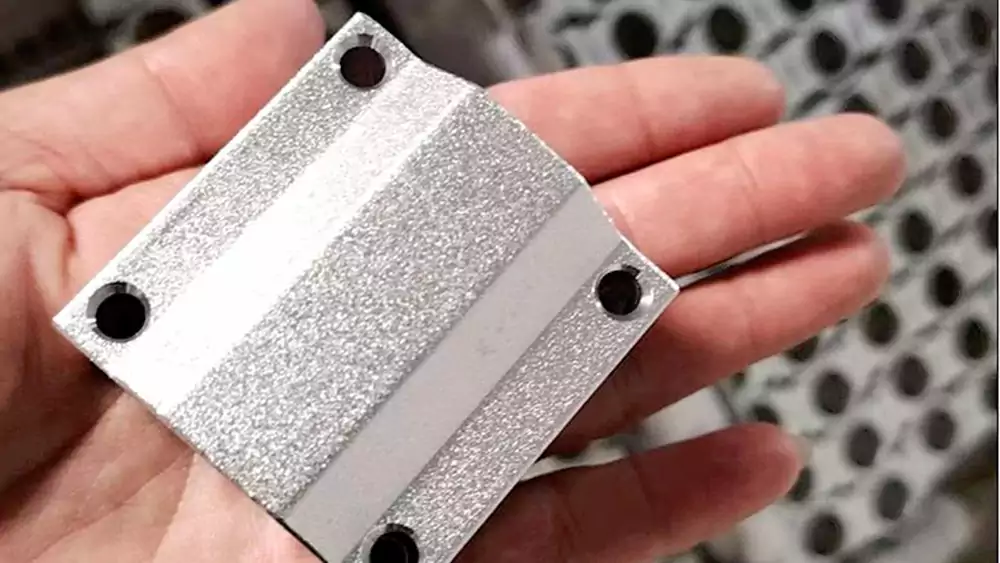

Precision Aluminium Investment Casting

From complex prototypes to high-volume production. We provide a complete one-stop solution including casting, 5-axis CNC machining, and surface finishing for automotive and industrial applications.

Aluminium Material Properties

Aluminium offers an exceptional combination of lightweight, strength, and corrosion resistance, making it ideal for precision investment casting applications across multiple industries.

Lightweight

Aluminium has a density approximately one-third that of steel, offering significant weight savings without compromising structural integrity.

- Density: 2.7 g/cm³ (vs. steel: 7.8 g/cm³)

- High strength-to-weight ratio

- Reduces energy consumption in moving parts

Corrosion Resistance

Forms a protective oxide layer that prevents further oxidation, making it suitable for harsh environments and outdoor applications.

- Natural oxide layer protection

- Excellent for marine & chemical environments

- Can be enhanced with anodizing

High Performance

Excellent thermal and electrical conductivity combined with good machinability and weldability for diverse engineering applications.

- Thermal conductivity: 237 W/m·K

- Electrical conductivity: 37.7 MS/m

- Non-magnetic & non-sparking properties

Why Choose Aluminium Investment Casting?

Aluminium investment casting offers unique advantages over other manufacturing methods, especially for complex, high-precision components.

Create intricate geometries, thin walls, and internal features that would be impossible or cost-prohibitive with other manufacturing methods.

Minimal post-processing required with excellent dimensional accuracy (±0.005 per inch) and surface finish (Ra 3.2-6.3).

Lower tooling costs compared to die casting, ideal for low to medium volume production (10-10,000+ parts).

Minimal material waste with high yield rates. Aluminium is 100% recyclable without quality degradation.

Common Aluminum Alloy Grades

Industry-standard aluminum alloys optimized for investment casting applications

| Alloy Grade | Tensile strength (MPa) | Yield strength (MPa) | Elongation (%) | Typical applications |

|---|---|---|---|---|

| A356-T6 | 262-283 | 185-205 | 3-5 | Aerospace, automotive wheel hubs, structural components |

| A357-T6 | 345-359 | 290-310 | 3-5 | High-performance aerospace components, premium automotive parts |

| A380 | 324 | 159 | 3.5 | General die-cast components, consumer products |

| A413 | 296 | 145 | 3.5 | Complex thin-walled castings, electronic enclosures |

| 355-T6 | 234-262 | 165-193 | 3-4 | Marine hardware, hydraulic components |

| 7075-T6 | 538-572 | 469-503 | 6-8 | High-strength aerospace structural components, military applications |

Data source: International Aluminium Alloy Standards | Tensile strength units: megapascals (MPa) | All values represent typical ranges

- Alloy Selection Guidance

Our engineering team provides free DFM (Design for Manufacturing) consultation to help you select the optimal aluminium alloy for your application based on strength requirements, corrosion resistance, thermal properties, and cost considerations.

Our aluminium processing capabilities

Allied Metal handles the entire supply chain, reducing your lead times and management costs.

Tons Annual Capacity

Machining Centers

9001 & TS 16949

Precision Casting

Automated shell drying lines ensuring consistent quality. 0.01kg to 85kg capacity per part.

CNC Machining

2 Factories, 200+ machines including 5-Axis centers for tight tolerances (±0.005mm).

Finish & Inspect

Heat treatment (T6), Anodizing, Powder Coating + 100% CMM & X-Ray inspection.

Casting Tolerance

Surface Roughness

Casting Weight Range

Max Outline Dimension

Why Partner With Allied Metal?

We solve the “Gap” for OEMs and SMEs: Professional engineering support without the massive MOQ of Tier-1 foundries.

We don't just print your CAD—our engineers analyze wall thickness, draft angles, and gating to optimize manufacturability and reduce your tooling costs.

Receive functional samples in 7-10 days using PMMA patterns or 3D printing. Validate your design before committing to expensive hard steel tooling.

In-house CMM, spectrometers, and optical projectors ensure every batch meets VDG P690 standards with full traceability and comprehensive documentation.

We accommodate lower MOQs for SMEs while maintaining capacity to scale for global automotive brands—seamless transition from prototype to production.

Advanced Manufacturing Capabilities

A 10,000 sq.m. precision casting facility equipped with automated production lines and 200+ CNC machines ensures consistent quality and rapid delivery.

Manufacturing Facilities

- 10,000 sq.m. precision casting facility

- Automated shell drying lines

- Annual capacity: 1,000+ metric tons

- 200+ CNC machines (5-axis capability)

- Maximum casting size: 600mm, 85kg

Comprehensive Testing

- Coordinate Measuring Machines (CMM)

- X-ray inspection & dye penetrant testing

- Spectrometer chemical analysis

- Tensile & hardness testing

- Leak testing & pressure testing

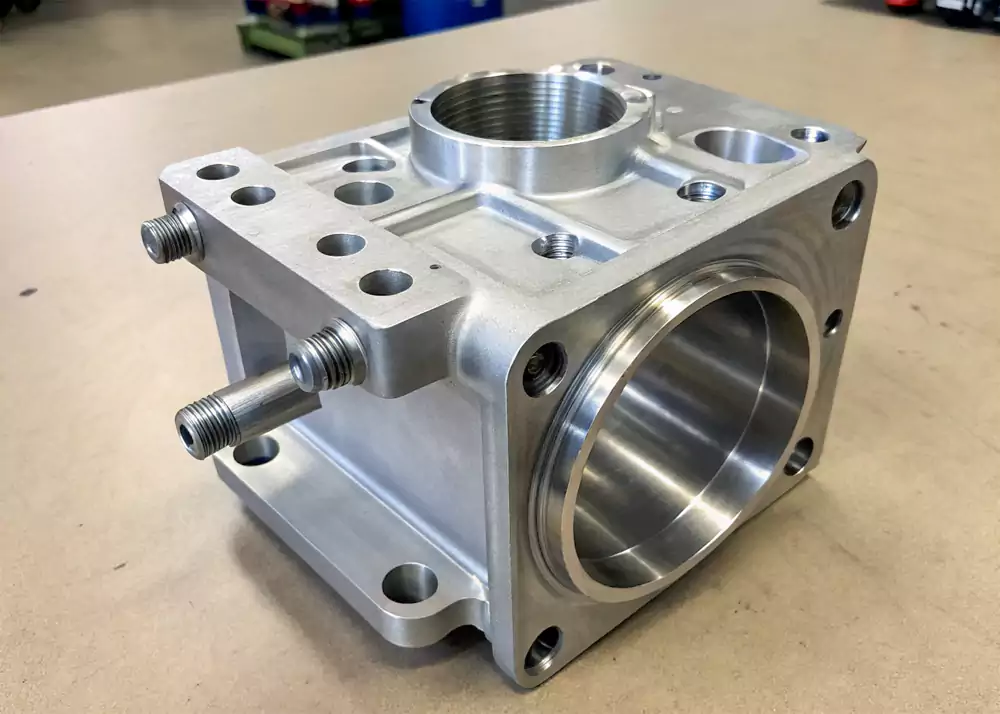

Case Study: Aerospace Control Valve Housing

High-integrity casting solution for flight-critical hydraulic systems.

The Challenge

A leading aerospace manufacturer needed to replace a heavy stainless steel housing with a lightweight alternative. The part required complex internal oil channels that could not be machined from solid blocks, and strictly limited weight to under 3.0kg while withstanding 350+ MPa pressure.

Allied Metal Solution

We engineered a transition to Aluminum A357-T6 using precision investment casting.

- Material Engineering: Selected A357 alloy for its superior strength-to-weight ratio and pressure tightness.

- DFM Optimization: Redesigned internal webbing to reduce mass without compromising stiffness.

- Precision Machining: 5-Axis CNC machining achieved the critical ±0.015mm tolerance on spool bores.

35% Weight Reduction Achieved

Plus 100% pass rate on X-Ray & Pressure Tests over 18 months.

Industry Applications

Trusted by leading companies across critical industries worldwide

🛩️ Aerospace Components

Aircraft structural parts, engine components, landing gear assemblies, and critical flight control systems requiring lightweight, high-strength solutions.

🚗 Automotive Parts

Engine blocks, transmission housings, suspension components, brake calipers, and custom performance parts for automotive and racing applications.

⚕️ Medical Devices

Surgical instruments, prosthetic components, diagnostic equipment housings, and biocompatible implant-grade aluminum parts for healthcare applications.

⚙️ Industrial Machinery

Hydraulic valve bodies, pump housings, robotic components, and precision mechanical parts for manufacturing and automation systems.

💻 Electronics & Telecommunications

Heat sinks, RF shielding enclosures, antenna components, and thermal management solutions for high-performance electronic devices.

⚓ Marine & Defense

Corrosion-resistant marine hardware, naval vessel components, military equipment parts, and specialized defense system housings.

Start Your Aluminum Casting Project

Whether you need prototype samples or full production runs, our engineering team provides end-to-end solutions from design to manufacturing, helping you reduce costs and accelerate time-to-market.