What is Alloy Steel Investment Castings?

Alloy steel is an iron-carbon alloy formed by adding an appropriate amount of one or more alloying elements to ordinary alloy steel.

According to the different added elements, and adopt appropriate processing technology, can obtain high strength, high toughness, wear resistance, corrosion resistance, low-temperature resistance, high-temperature resistance, non-magnetic and other special properties.

Alloy steel is mainly divided into two categories: low alloy steel and high alloy steel. Investment cast alloy steels are usually low alloy steels.

Advantages of Alloy Steel Casting

01. High temperature resistance, low temperature resistance, abrasion resistance, strong corrosion resistance

02. Stable, not easy to oxidize and deform

03. Easy to process, can be processed in various shapes and sizes

04. Long service life of alloy steel material

05. Flexibility, according to user needs to add different alloying elements

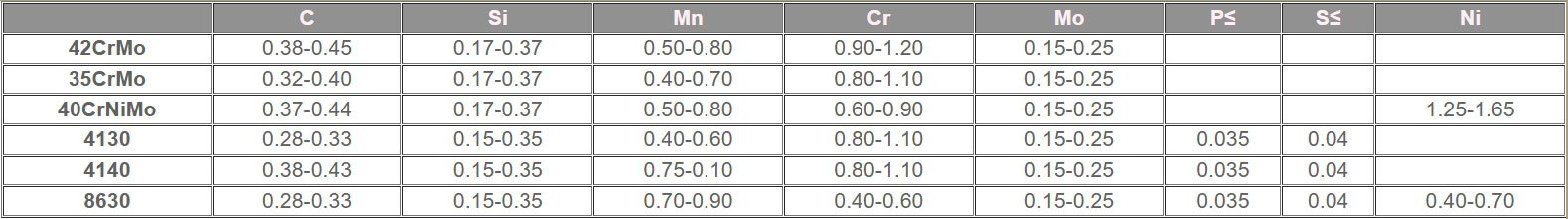

Common Alloy Steel Casting Materials

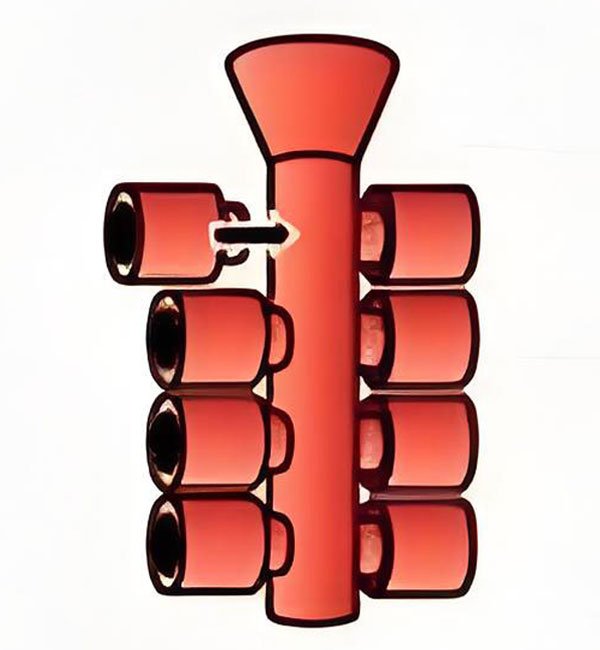

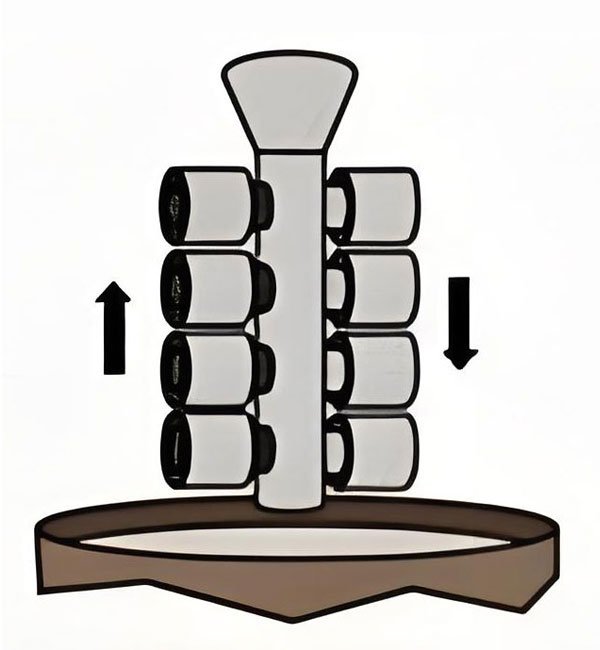

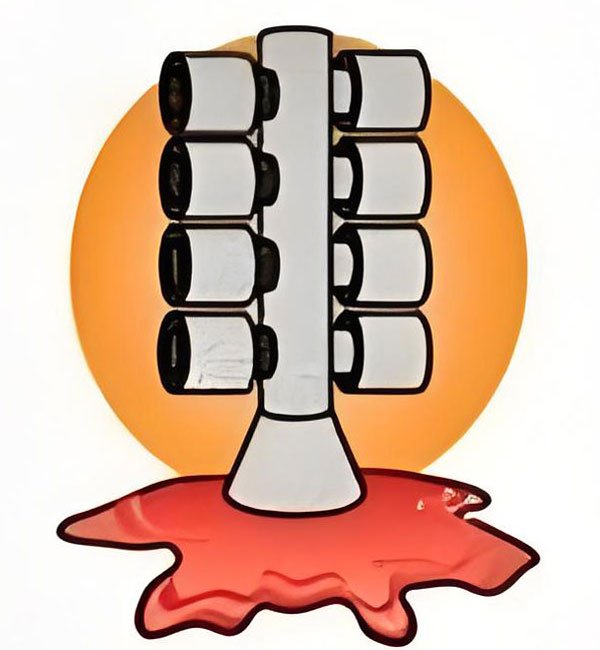

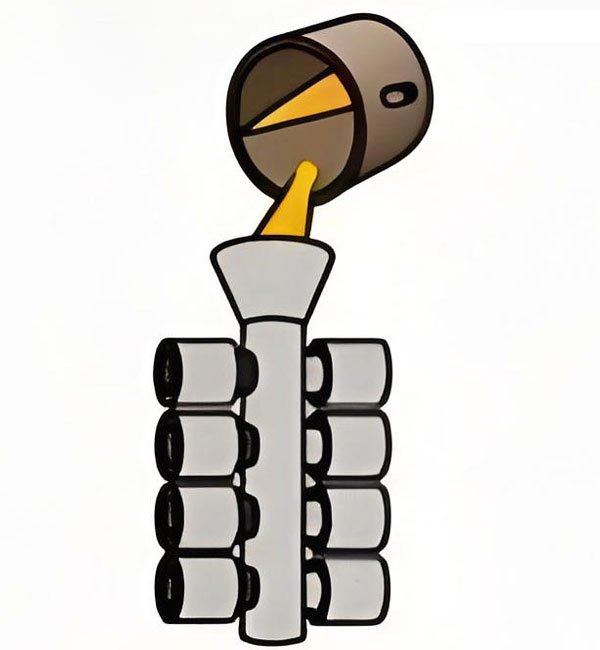

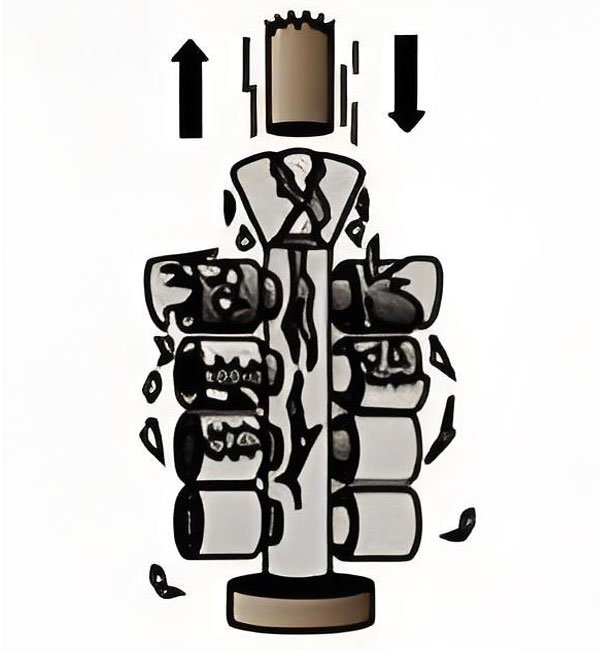

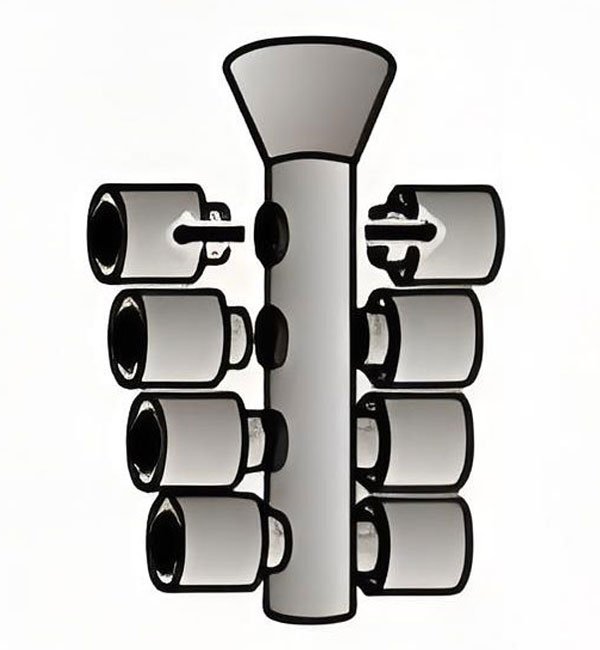

The process of Alloy Steel Casting

Why Choose Allied Metal For Alloy Steel Casting?

Allied Metal is a premier lost wax investment casting foundry,has been certified to IATF16949:2016 and ISO90001:2015, and has a machining shop for secondary processing.

Ⅰ:Our advantages:

State-of-the-Art Facility:

At Allied Metal, we pride ourselves on our advanced manufacturing capabilities. Our facility is equipped with an automatic shell drying line, ensuring consistent quality and efficiency in every casting we produce. With a monthly production capacity of 80 tons, we are poised to meet the high-volume needs of our clients while maintaining exceptional standards.

Quality Assurance:

Quality is at the core of everything we do. Our commitment to excellence is demonstrated through our ISO 9001 and TS 16949 certifications, ensuring that our processes and products adhere to the highest international standards. We continuously invest in our quality management systems to guarantee the reliability and performance of our castings.

Our Products:

Our foundry specializes in producing a wide range of castings tailored to the specific requirements of the automotive industry. Whether it’s components for engines, transmissions, or other critical automotive parts, our castings are designed to deliver superior strength, durability, and precision.

Ⅱ:The Services We Can Provide:

Investment Casting

Provide investment casting solutions and services. Our main business scope includes precision casting, processing, and sales of metals such as stainless steel, carbon steel, and alloy steel.

Precision Machining

Excellent precision machining supplier with over 40 CNC machine tools, including large vertical gantry milling machines, with a working range of 6500 * 4200 * 1800mm.

Ⅲ:Our Quality Assurance:

We have the most advanced spectrometer, coordinate measuring machine, hardness tester and tensile tester to help us better inspect the performance of the castings to guarantee the quality of the products.

Of course, our QC team checks for all surface issues, including surface defects such as oxidized skin, cracks, pores, shrinkage and bubbles.

With advanced machinery and equipment and a professional technical team, we are confident that we can help you solve these problems, whether you are worried about very small tolerances, complex shapes of castings, or surface details.

Type of investment casting material

Stainless steel castings area general name for castings made of various stainless steel materials (also called stainless steel investment casting)Read More…

Carbon steel is one of the main materials in the current cast steel industry. lt has the advantages of low cost, high wear resistance, easy preparationRead More…

Alloy steel is mainly divided into two categories: low alloy steel and high alloy steel.Investment cast alloy steels are usually low alloy steelsRead More…

If you need a quote or free consultation, please contact us.

- Tel:+86 1996 3099 511

- Email:quote@alliedcn.com

- Online:8:30a-6:00p Monday to Friday

- Address:No.5608,Xinhua Road,Weifang,Shandong,China