Many projects fail early because flange manufacturing choices are made too fast. I have seen cost, lead time, and performance issues appear simply because the process was misunderstood.

Flanges can be produced by casting or forging. The correct method depends on load, geometry, quantity, and cost targets rather than a single “best” manufacturing rule.

I have spent more than twenty years working with investment casting and machining. Over time, I learned that flange decisions are rarely black and white. When engineers and buyers understand the process logic, projects move faster and risks drop.

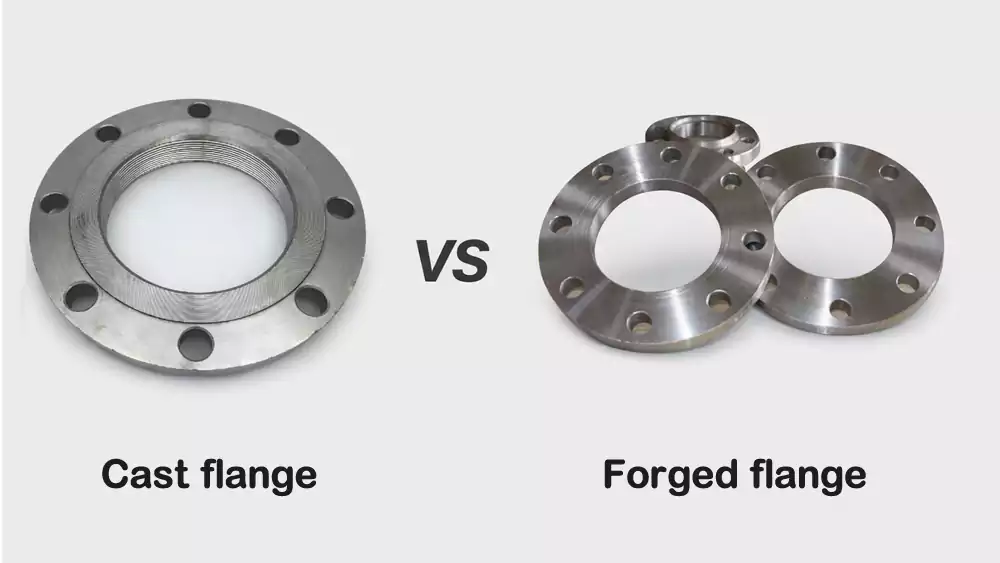

Cast vs Forged Flanges: Manufacturing Methods and Key Differences?

Many teams compare cast and forged flanges only by strength data. That approach often leads to wrong assumptions and higher costs.

Casting forms flanges by pouring molten metal into molds, while forging shapes flanges by compressing solid metal. These two methods create very different structures, limits, and cost models.

Casting allows metal to flow freely into complex shapes. Forging relies on force to shape metal along controlled paths. Each method has advantages that fit different design goals.

Manufacturing Principles and Mechanical Behavior

From a technical view, forging produces directional grain flow. This improves fatigue strength1 and load resistance. That is why forged flanges are common in high-pressure pipelines and critical joints. Casting produces a more uniform internal structure. While peak strength is lower, it allows greater design freedom and stable properties in all directions.

| Factor | Casting | Forging |

|---|---|---|

| Grain structure | Random | Directional |

| Strength | Moderate | High |

| Fatigue resistance | Medium | High |

| Shape freedom | Very high | Limited |

| Tooling cost | Lower | Higher |

In real projects, strength is not the only target. Many custom flanges do not operate near material limits. In those cases, flexibility and cost control matter more.

Cost, Tooling, and Lead Time

Forging requires dies, presses, and longer setup. This increases upfront cost and makes small batches inefficient. Investment casting needs tooling as well, but it is cheaper and faster to modify. For non-standard flanges, this difference often defines the project timeline.

How to Choose Between Cast and Forged Flanges?

Choosing a process without clear criteria creates risk. I often see forged flanges used where they are not required.

Cast flanges suit complex shapes and small to medium batches, while forged flanges suit standard designs under high pressure and cyclic loads.

I guide customers through simple questions instead of technical debates.

Decision Factors That Matter Most

Pressure rating2 is the first filter. High pressure favors forging. Geometry is the second filter. Complex shapes favor casting. Quantity is the third filter. Small batches favor casting.

| Decision Factor | Better for Casting | Better for Forging |

|---|---|---|

| High pressure | No | Yes |

| Complex geometry | Yes | No |

| Small batch | Yes | No |

| Standard flange | No | Yes |

| Cost sensitivity | Yes | Sometimes |

Engineer vs Procurement Perspective

Engineers focus on safety margins. Buyers focus on price and delivery. I often explain where extra strength adds no value. When both sides align, decisions become faster and more confident.

Materials and Quality Characteristics of Custom Flanges?

Material choice directly affects performance and manufacturability. I have seen correct designs fail because the alloy choice was wrong.

Carbon steel, stainless steel, alloy steel, and duplex steel are common flange materials, but each behaves differently in casting and forging.

Casting supports a wider alloy range and better chemical control. Forging limits material options due to formability.

Material Matching with Process

Carbon steel works well in both methods. Stainless steel benefits from casting when shapes are complex. Duplex steel often favors casting due to forging difficulty.

| Material | Casting Suitability | Forging Suitability | Typical Use |

|---|---|---|---|

| Carbon steel | High | High | Industrial piping |

| Stainless steel | Very high | Medium | Medical, food |

| Alloy steel | High | High | Automotive |

| Duplex steel | High | Low | Corrosion service |

Identifying Cast vs Forged Quality

Surface appearance gives clues, but it is not enough. Cast flanges show parting lines. Forged flanges show flow marks after machining. True quality comes from inspection, testing, and process control. I trust data more than appearance.

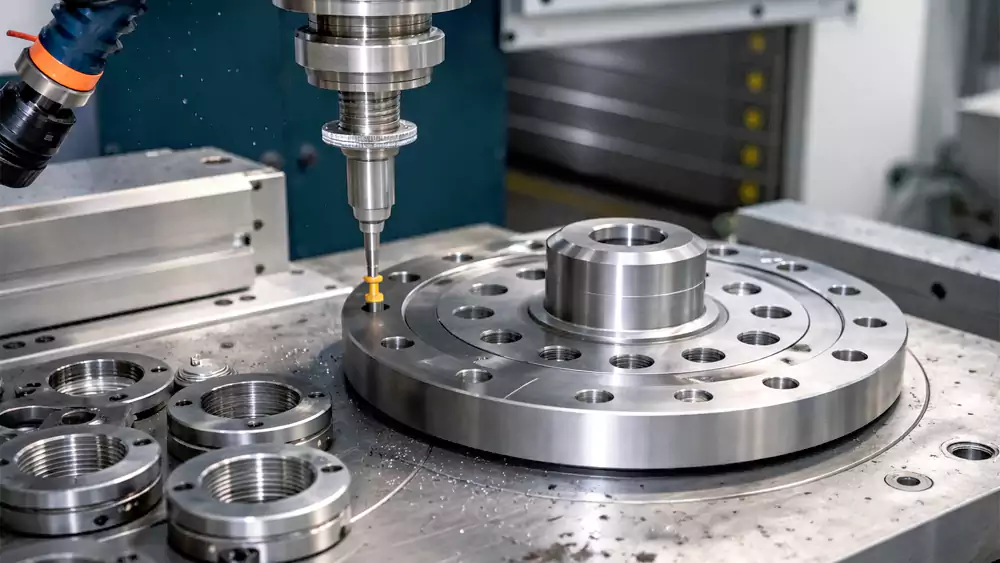

Cast + CNC Machining for Custom and Non-Standard Flanges?

Pure casting or pure forging rarely meets all needs. Combining casting with machining often delivers the best balance.

Investment casting combined with CNC machining provides design freedom, tight tolerances, and cost control for custom flanges.

Casting forms the near-net shape. CNC machining ensures precision where it matters.

Why CNC Finishing Is Critical

Sealing faces, bolt holes, and flatness require machining. CNC allows tight tolerances and repeatability. It also supports late design changes without new tooling.

Case Study: Custom Non-Standard Equipment Flange

I supported a project for industrial equipment requiring an offset flange with strict flatness control3.

| Parameter | Value |

|---|---|

| Material | ASTM A351 CF8M |

| Outer diameter | 185 mm |

| Thickness | 22 mm |

| Bolt holes | 8 × Ø11 mm |

| Flatness after machining | ≤0.05 mm |

| Quantity | 120 pcs |

Investment casting created the complex shape. CNC machining4 finished sealing surfaces and holes. The customer reduced tooling cost by over 40% compared to forging.

Typical Applications and Industry Use Cases?

Different industries value different performance aspects. Matching the process to the industry reduces risk.

Custom cast flanges are common in automotive, medical, and industrial equipment, while forged flanges dominate high-pressure systems.

Automotive and motorcycle parts often require compact shapes and weight control. Medical devices require surface quality and material consistency. Industrial equipment values flexibility and repair speed. In these cases, casting plus machining is often the best fit.

Conclusion

Cast and forged flanges each have clear roles. The best results come from matching process, material, and machining to real service needs.

-

Understanding the fatigue types and fatigue strength of materials or structural components. ↩

-

Understanding pressure rating is crucial for selecting the right manufacturing method, ensuring safety and efficiency. ↩

-

Learn about the techniques and importance of flatness control in machining to ensure high-quality components. ↩

-

Explore this link to understand how CNC machining enhances precision and efficiency in manufacturing processes. ↩