One-Stop Customized Service

Non-standard customization

Investment Casting

Precision Machining

Surface Treatment

20+ Years

400+Customers

1000T

99.9%

About Us

Allied Metal located in Weifang City, Shandong Province, which has convenient traffic and developed industry. It is an excellent supplier of precision casting products in China.

Allied Metal adopts the advanced silicone sol investment casting process, specialising in the production of precision castings and machined parts in a wide range of steel, stainless steel, carbon steel and alloy steel. We also have complete precision machining and surface treatment capabilities.

Our company serves a wide range of markets, including nuclear power plants, high-speed rail, marine equipment, medical, food, industrial locks, automotive, electronics and electric power, petroleum equipment, instrumentation, architectural hardware, and aerospace companies. At present, we have established long-term and solid cooperative relationships with hundreds of customers.

We not only have excellent hardware infrastructure, but also have a mature technical team and more than 20 years of experience in production and processing, with an extremely high production capacity of precision metal parts per month, of which more than 80% are exported to the EU, the UK, the United States, Australia and other countries and regions.

A truly leading investment casting plant in China

Allied Metal is a premier lost wax investment casting foundry dedicated to serving the automotive industry with precision and reliability.

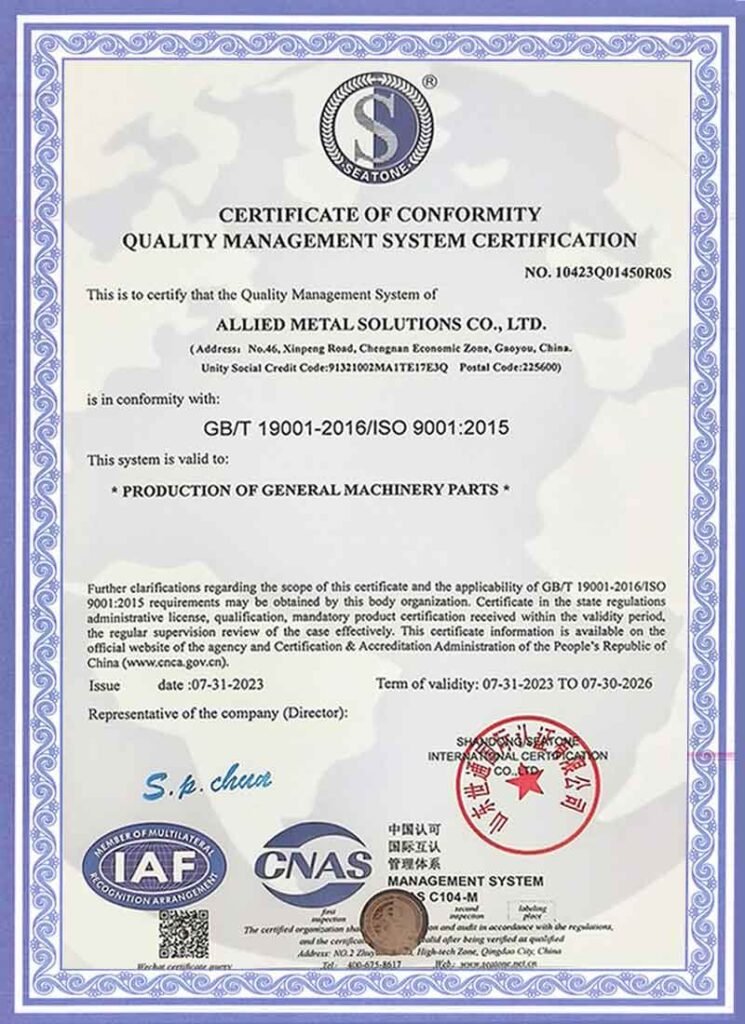

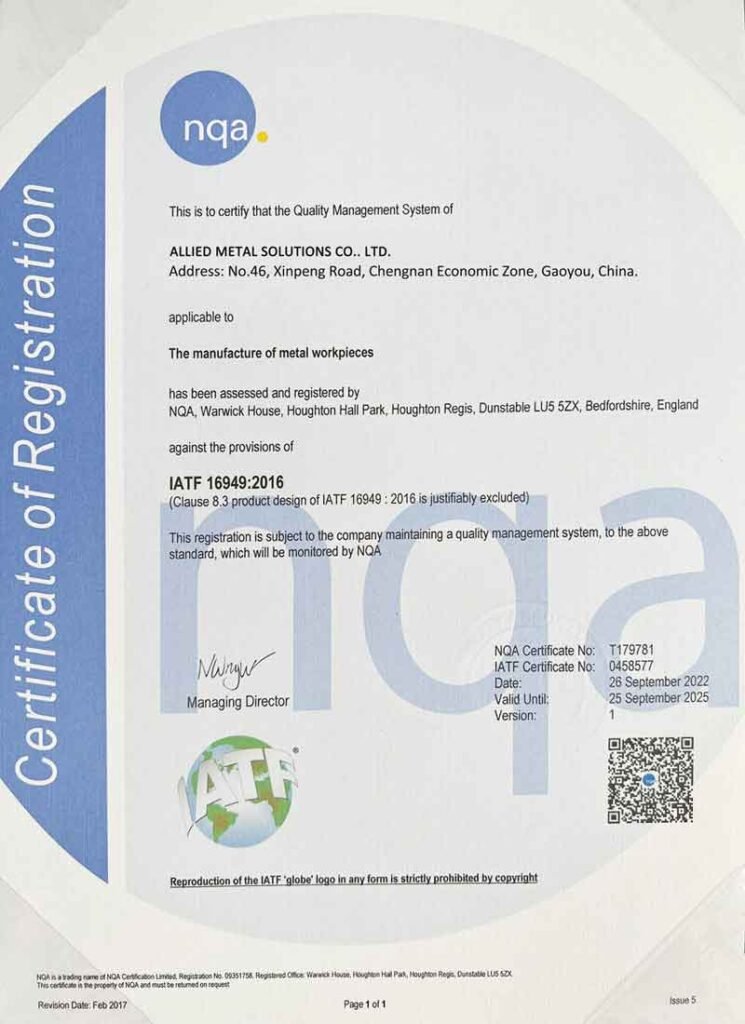

Allied Metal has been certified to IATF16949:2016 and ISO90001:2015, and has a machining shop for secondary processing.

Our CNC machine shop has a wide range of state-of-the-art machinery, including 3, 4 and 5-axis CNC machines, CNC lathes and CNC milling machines.

Our factory

Our certification

—— Production Process ——

Investment Casting Capabilities

— Casting tolerances: VDG P690 D1-D2, ISO8062-3-2007 DCTG4-6, GCTG4-6

— Casting Roughness: Ra 3.2-6.3

— Casting weight: 0.01kg-85kg

— Maximum Outline Dimension:600mm.

— Served industries: Automotive Parts,Hardware Parts,Hydraulic Parts,Medical Parts and Machinery Parts.

— Services Offered: Rapid Prototyping, Electropolishing, Secondary Machining, Heat Treatment, Surface Treatment

FAQ:

Products development with PROE,Solid Works and CAD tools.

Auto Parts,Valve Series Parts,Machine Parts,Hardware Series Parts.

Stainless steel,duplex stainless steel,alloy steel and carbon steel.

Lost wax with Silica Sol Techniques.

NO! – No minimum quantity! Allied provides prototypes and short to medium-run production machining services.

For the 3D drawing, we would prefer STEP, IGES, or X_T format. For the 2D drawing, we would prefer PDF format there are tolerances with the dimensions if possible.

Allied accepts payment in two ways: 1. Bank to bank wire transfer; 2. PayPal.

Lead times are 2 to 3 weeks for prototypes and 4 weeks for production runs. Emergency and rush services are available.

—— Partners of Allied Metal ——

If you need a quote or free consultation, please contact us.

- Tel:+86 1996 3099 511

- Email:quote@alliedcn.com

- Online:8:30a-6:00p Monday to Friday

- Address:No.5608,Xinhua Road,Weifang,Shandong,China