Custom Turbine Blade Manufacturing

Precision Investment Casting & Machining Solutions for Automotive, Aerospace and Industrial Equipment Manufacturers Worldwide

- 20+ Years Experience in Precision Casting & Machining

- Custom Designs Based on Your Drawings or Samples

- Complex Geometry & Tight Tolerances

- ISO-Compliant Quality Control

Our Custom Turbine Blade Capabilities

From prototype to serial production, we offer comprehensive manufacturing solutions for complex turbine blades.

Precision lost-wax casting for complex internal structures, thin walls, and excellent surface finish.

- Reduced machining allowance

- Complex cooling structures

- Near-net-shape production

3-, 4- and 5-axis CNC machining services for precise blade profiles and tight tolerances.

- Consistent batch production

- Complex blade geometries

- High-precision finishing

Complete finishing and treatment services to meet your specific performance requirements.

- Drilling, grinding & balancing

- Heat treatment

- Surface treatments & coatings

Industry Applications

We serve manufacturers across critical industries requiring high-performance turbine components.

Automotive Industry

High-performance turbine blades for turbochargers and exhaust systems that withstand extreme temperatures and rotational speeds.

- Turbocharger turbine blades

- High-temperature exhaust components

- Performance and racing applications

Why custom solutions?

OEMs and performance manufacturers require tailored designs to optimize efficiency, reduce weight, and meet specific engine requirements.

Aerospace & Aviation

Flight-critical turbine components that meet the highest standards for safety, weight, and performance in extreme conditions.

- Engine turbine blades

- Auxiliary power units (APU)

- Helicopter engine components

Why custom solutions? Aerospace applications demand lightweight, high-strength materials and complex cooling structures that can only be achieved through precision manufacturing.

Industrial Equipment

Durable turbine blades for power generation, manufacturing, and energy applications that require reliability and efficiency.

- Gas and steam turbines

- Power generation systems

- Industrial compressors

Why custom solutions? Industrial applications often require specialized designs to optimize for specific operating conditions, fuel types, and maintenance cycles.

Customizable Turbine Blade Types

We manufacture a wide range of turbine blade types to meet diverse application requirements. Our expertise covers everything from simple prototypes to complex, high-performance aerospace components.

Turbine Rotor Blades

High-speed rotating blades that extract energy from hot gases in jet engines, power generation turbines, and industrial applications.

Stator Blades

Stationary blades that direct flow onto rotor blades, optimizing fluid dynamics and improving overall turbine efficiency.

Nozzle Guide Vanes

Precision components that control gas flow direction and velocity in turbine engines for optimal performance.

Turbocharger Blades

High-performance blades for automotive turbochargers, designed to withstand extreme temperatures and rotational speeds.

Prototype Blades

Custom designs for testing and development, allowing engineers to validate new concepts before full-scale production.

Reverse Engineering

Recreate existing blades from samples or worn parts, restoring performance without original design documentation.

Compressor Blades

Aerodynamically designed blades that compress incoming air in gas turbine engines, increasing pressure for combustion.

Impeller Blades

Radial or mixed-flow blades for pumps, compressors, and blowers that transfer energy to fluids through rotation.

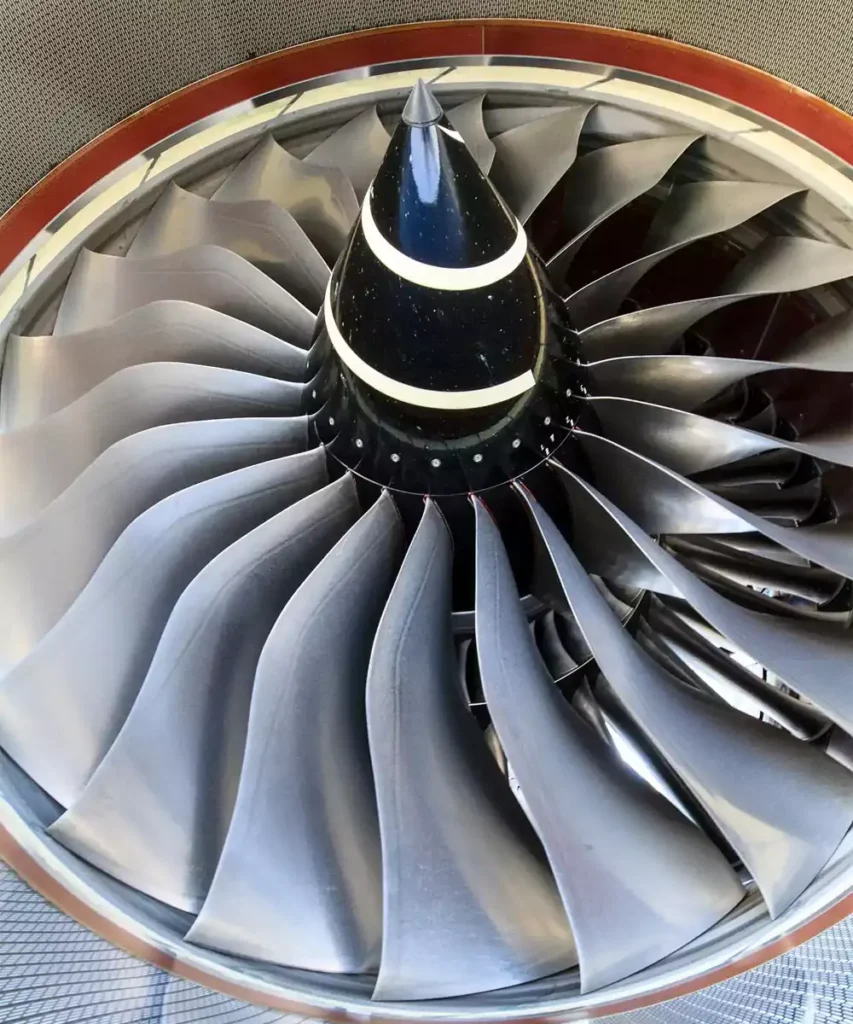

Fan Blades

Large-diameter blades for aircraft engines, cooling towers, and industrial ventilation systems requiring high airflow.

Wind Turbine Blades

Large-scale blades for renewable energy generation, designed for optimal aerodynamic efficiency and structural integrity.

Steam Turbine Blades

Blades designed for high-pressure steam environments in power generation plants, requiring corrosion and erosion resistance.

Marine Turbine Blades

Corrosion-resistant blades for ship propulsion systems and onboard power generation in marine environments.

Turbine Rotor Blades

High-speed rotating blades that extract energy from hot gases in jet engines, power generation turbines, and industrial applications.

Turbocharger Blades

High-performance blades for automotive turbochargers, designed to withstand extreme temperatures and rotational speeds.

Compressor Blades

Aerodynamically designed blades that compress incoming air in gas turbine engines, increasing pressure for combustion.

Impeller Blades

Radial or mixed-flow blades for pumps, compressors, and blowers that transfer energy to fluids through rotation.

Fan Blades

Large-diameter blades for aircraft engines, cooling towers, and industrial ventilation systems requiring high airflow.

Wind Turbine Blades

Large-scale blades for renewable energy generation, designed for optimal aerodynamic efficiency and structural integrity.

Steam Turbine Blades

Blades designed for high-pressure steam environments in power generation plants, requiring corrosion and erosion resistance.

Marine Turbine Blades

Corrosion-resistant blades for ship propulsion systems and onboard power generation in marine environments.

Stator Blades

Stationary blades that direct flow onto rotor blades, optimizing fluid dynamics and improving overall turbine efficiency.

Nozzle Guide Vanes

Precision components that control gas flow direction and velocity in turbine engines for optimal performance.

Prototype Blades

Custom designs for testing and development, allowing engineers to validate new concepts before full-scale production.

Reverse Engineering

Recreate existing blades from samples or worn parts, restoring performance without original design documentation.

Don’t see your specific blade type? Our engineering team can design and manufacture custom turbine blades for virtually any application.

Materials & Performance Options

We select materials based on your specific requirements for temperature, corrosion, and mechanical stresses.

| Material Category | Key Properties | Typical Applications |

|---|---|---|

| Nickel-based Superalloys | Exceptional high-temperature strength, oxidation resistance, creep resistance | Aerospace engine blades, industrial gas turbines |

| Stainless Steel | Excellent corrosion resistance, good strength, cost-effective | Marine turbines, chemical processing, exhaust systems |

| Heat-resistant Alloy Steel | High temperature strength, good fatigue resistance | Power generation turbines, automotive turbochargers |

| Titanium Alloys | High strength-to-weight ratio, excellent corrosion resistance | Aerospace components, high-performance automotive |

| Aluminum Alloys | Lightweight, good thermal conductivity, corrosion resistant | Low-temperature applications, prototype development |

Our engineering team provides free DFM consultation to help you select the optimal material based on strength requirements, temperature range, corrosion resistance, and cost considerations.

Quality Control & Standards

Our rigorous quality assurance process ensures every turbine blade meets the highest performance standards.

Dimensional Inspection

Advanced CMM (Coordinate Measuring Machine) inspection ensures precise adherence to specifications.

- CMM with ±0.002mm accuracy

- Optical projectors for profile verification

- Full GD&T reporting available

Material Testing

Comprehensive material verification to ensure proper alloy composition and properties.

- Spectrometer analysis

- Mechanical property testing

- Microstructure examination

Certifications & Standards

We adhere to international quality standards and customer-specific requirements.

- ISO 9001:2015 certified

- TS 16949 for automotive

- VDG P690, ISO8062-3 standards

Customization Process

Our streamlined 5-step process ensures efficient collaboration from design to delivery.

Send us your drawings, CAD files, or samples for evaluation.

Our engineers provide DFM feedback and feasibility analysis.

Receive detailed quote with lead time and production plan.

Tooling development and sample approval before mass production.

Full-scale production with quality checks and on-time delivery.

Why Choose Allied Metal

With over 20 years of hands-on manufacturing experience, we bridge the gap between design and production.

Our founder has 20+ years as a machinist, ensuring deep understanding of both casting and machining integration.

200+ machines, specialized in full-process manufacturing of complex components like turbine blades—from casting to micron-level machining.

Work directly with our engineering team, no middlemen or sales agents delaying communication.

Serving clients in EU, North America, and Asia with expertise in international standards and export logistics.

Gallery Display

Frequently Asked Questions

Common questions from engineers and procurement professionals about our turbine blade manufacturing.

What tolerances can you achieve for turbine blades?

We typically achieve casting tolerances of VDG P690 D1-D2 (ISO8062-3 DCTG4-6), which translates to ±0.005mm per inch. For machined features, we can hold ±0.015mm on critical dimensions like bore diameters and blade profiles. Final tolerances depend on part size, geometry, and material.

What is your typical lead time for prototype and production?

Prototype lead times are typically 4-6 weeks from design approval, including tooling development. For production orders, lead times range from 8-12 weeks depending on quantity and complexity. We offer expedited services for urgent projects with additional lead time options available.

Do you support small batch orders?

Yes, we specialize in small to medium batch production (10-10,000+ parts). Our flexible manufacturing approach allows us to accommodate lower MOQs that larger foundries typically won’t accept, while maintaining the capability to scale for larger production runs when needed.

Can you manufacture based on samples only (without drawings)?

Yes, we offer reverse engineering services. Send us a physical sample, and we can 3D scan it to create CAD models and drawings for production. We’ll also provide DFM recommendations to improve the design for manufacturability if needed.

Which countries do you ship to and what are the payment terms?

We ship worldwide, with extensive experience exporting to the EU, North America, Australia, and Asia. Standard payment terms are 30% deposit with order, 70% before shipment. For established customers, we offer flexible payment arrangements including letter of credit (L/C) options.

Perhaps you would like to know more about these issues?

- Click For Details

Related articles:

Start Your Turbine Blade Project

Whether you need prototype samples or full production runs, our engineering team provides end-to-end solutions from design to manufacturing.