Struggling to manufacture complex turbine blades with the required material integrity? Machining these parts from solid blocks is incredibly expensive, wasteful, and often impossible with high-temperature superalloys.

Investment casting is the primary method for producing turbine blades. It excels at creating complex, hollow airfoil shapes from high-performance superalloys with the precision and material integrity that aerospace and energy sectors demand.

After years in the casting industry, I've seen how investment casting transforms turbine blade manufacturing, because it enables the direct casting of complex geometries into near-net shape, thereby minimizing material waste and reducing the need for secondary machining. The process delivers what aerospace engineers need most: reliability, precision, and consistency. Let me walk you through why this method dominates turbine blade production.

Why is a Turbine Blade Made by investment Casting?

With so many manufacturing methods available, why is casting the preferred choice for turbine blades? What makes this process uniquely suited for these critical, high-performance components?

Turbine blades are made by investment casting because the process can create their complex, hollow airfoil shapes and handle the high-temperature superalloys required, which are extremely difficult to machine.

Diving Deeper into the Manufacturing Choice

The decision to use investment casting for turbine blades is driven by two main factors: the complexity of the part's design and the difficulty of the materials used. For a sourcing manager like Michael, understanding these drivers is key to appreciating why this process is the industry standard.

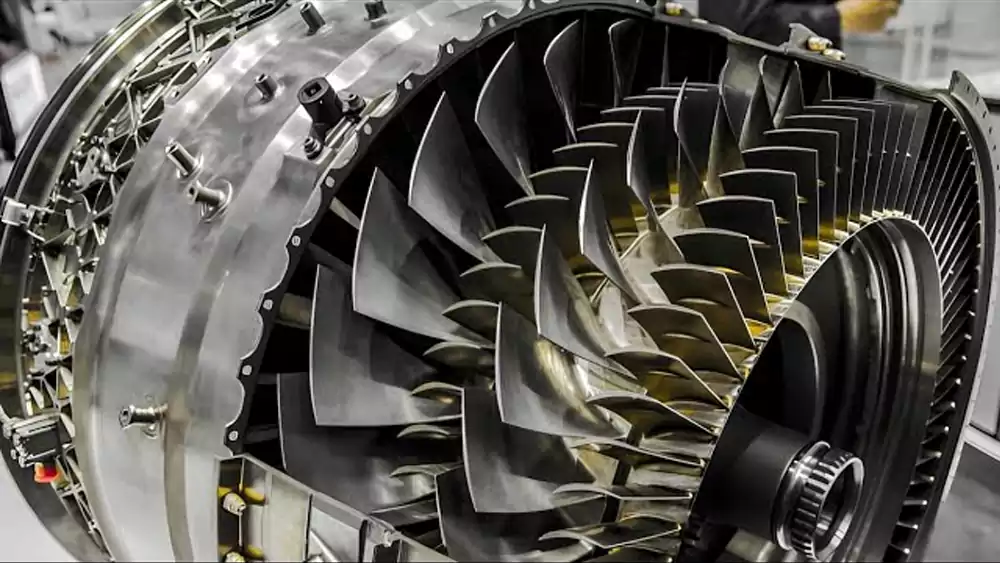

1. Complexity of Turbine Blade Geometry

- Airfoil Shapes: Turbine blades are not simple parts. They have highly complex, three-dimensional airfoil shapes that are optimized for aerodynamic performance. These are not shapes that can be easily created with standard machining operations.

- Internal Cooling Passages: Modern high-performance turbine blades are not solid. They have incredibly intricate, serpentine internal passages. Cool air is forced through these channels during operation to prevent the blade from melting. Investment casting is one of the only processes that can create these complex internal features in a single piece.

2. Material Challenges for Turbine Blades

- High-Temperature Superalloys1: Turbine blades operate in one of the most extreme environments imaginable, with temperatures often exceeding the melting point of the metal itself. They are made from nickel-based or cobalt-based superalloys. These materials are specifically designed to retain their strength at very high temperatures.

- Poor Machinability: A direct consequence of their high-temperature strength is that these superalloys are notoriously difficult to machine. They are tough, gummy, and cause rapid tool wear. Machining a complete turbine blade from a solid block of a superalloy would be incredibly time-consuming, wasteful, and prohibitively expensive.

Investment casting elegantly solves both of these problems. It allows these difficult-to-machine materials to be formed directly into the complex, hollow shape of a turbine blade in a single, efficient process.

How Does the Investment Casting Process for Turbine Blades Work?

How do you create a complex, hollow metal part from a liquid? What are the key steps in the investment casting process used for turbine blades?

The process involves creating a wax pattern of the blade, including its internal passages, coating it in a ceramic shell, melting out the wax, and then pouring molten superalloy into the ceramic mold.

Investment Casting Process for Turbine Blades

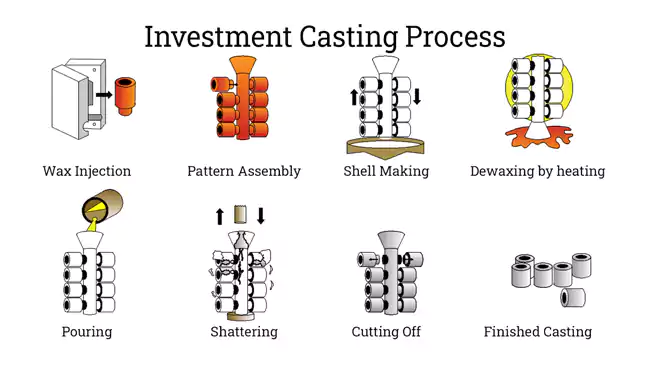

The investment casting process, also known as the "lost-wax" process, is a multi-step procedure that allows for the creation of parts with incredible detail and accuracy. For a critical component like a turbine blade, every step is meticulously controlled.

Here is a breakdown of the workflow:

- Tooling and Wax Pattern Injection2: The process begins with the creation of a high-precision metal die (the tool). A specialized wax is injected into this die to create a perfect replica of the final turbine blade. Critically, pre-formed ceramic cores3 are placed inside the die before injection. These cores will form the intricate internal cooling passages of the blade.

- Wax Tree Assembly: The individual wax patterns are then attached to a central wax rod, called a sprue, to create a tree-like assembly. This allows multiple blades to be cast at once.

- Ceramic Shell Building: The entire wax tree is then dipped repeatedly into a ceramic slurry and coated with a fine sand-like material (stucco). This process is repeated many times, building up a thick, robust ceramic shell around the wax patterns.

- Dewaxing (The "Lost Wax"): The ceramic shell is placed in a high-pressure steam autoclave. The heat melts the wax, which flows out of the shell, leaving behind a hollow ceramic mold that is a perfect negative impression of the turbine blades.

- Casting: The hollow ceramic mold is preheated to a high temperature and then filled with the molten superalloy in a vacuum furnace. The vacuum prevents any impurities from contaminating the metal.

- Finishing: After the metal cools and solidifies, the ceramic shell is broken away. The individual blades are cut from the tree, and the internal ceramic cores are chemically leached out. The blades then go through a series of finishing and inspection steps to ensure they meet the exact specifications.

Benefits of Investment Casting in Turbine Blade Manufacturing

Why is this complex process worth the effort? What are the key advantages that make investment casting the superior choice for manufacturing turbine blades?

The benefits include the ability to create highly complex shapes with internal passages, minimal material waste, excellent surface finish, and tight dimensional tolerances, which reduces the need for costly secondary machining.

Advantages of Investment Casting for Turbine Blades

For a sourcing managers, who must balance cost, quality, and lead time, the advantages of investment casting for turbine blades are clear and compelling. The process delivers a level of performance and efficiency that other methods cannot match for this specific application.

Here are the primary benefits:

- Design Freedom and Complexity: This is the most significant advantage. Investment casting allows for the creation of the most complex geometries, including the thin, aerodynamic airfoil shapes and the intricate internal cooling passages that are essential for modern turbine blade performance.

- Near-Net-Shape Parts: The process produces parts that are very close to their final, or "net," shape. This is particularly important when working with expensive superalloys. By casting the part to near-net-shape, you dramatically reduce the amount of material that is wasted as machining chips.

- Reduced Need for Machining: Because the cast part is so close to the final shape, the amount of secondary machining required is minimized. Machining is typically only needed for critical interfaces, like the root of the blade where it attaches to the turbine disk. This saves a huge amount of time and cost.

- Excellent Surface Finish: Investment casting produces a much smoother surface finish than other casting methods like sand casting. This is important for the aerodynamic efficiency of the blade.

- Wide Range of Alloy Choices: The process is compatible with a huge variety of metals, including the nickel and cobalt-based superalloys that are essential for high-temperature applications.

- High Consistency and Repeatability: The use of a durable metal die to create the initial wax patterns ensures that every part produced is virtually identical, which is critical for quality control in the aerospace industry.

Parameters of Cast Turbine Blades?

Many buyers want to know what precision they can expect before placing an order.

Cast turbine blades can meet tight tolerances, with surface finish, material strength, and heat resistance tailored to aerospace and energy requirements.

| Parameter | Typical Range | Notes |

|---|---|---|

| Dimensional Tolerance | ±0.1–0.25 mm | Depends on blade size |

| Surface Roughness | Ra 1.6–3.2 µm | Often improved with blasting or polishing |

| Alloy Types | Nickel-based, Cobalt-based, Inconel | High heat resistance |

| Heat Resistance | Up to 1100°C | Needed in gas turbines |

| Production Volume | Small to medium batches | Aerospace and energy sectors |

I often tell customers that while casting delivers near-net shape, some machining is still needed on critical faces or holes. But compared to full machining, the effort is much less. This balance between precision and efficiency is why casting continues to be the best choice.

What are the Common Turbine Blade Applications?

Where are these high-tech components used? What are the main industries and applications that rely on the performance of investment cast turbine blades?

Investment cast turbine blades are critical components in the aerospace, power generation, and industrial sectors. They are used in jet engines, gas turbines for electricity, and industrial steam turbines.

Industrial Applications of Turbine Blades

Investment cast turbine blades are used in some of the most powerful and technologically advanced machines in the world. The reliability of these blades is paramount in every application.

Here are the key industries where they are used:

-

Aerospace (Jet Engines):

- This is the most demanding application. The high-pressure turbine blades in the "hot section" of a commercial or military jet engine are the most critical. They must withstand incredible temperatures and rotational forces. The safety of every flight depends on the integrity of these cast components.

-

Power Generation (Gas Turbines):

- Large, land-based gas turbines are used to generate electricity. These turbines are very similar in principle to jet engines and use large, investment cast blades. The efficiency and reliability of our power grid depend on the performance of these components.

-

Energy and Oil & Gas (Industrial Turbines):

- Smaller gas and steam turbines are used throughout the energy industry to power compressors, pumps, and other equipment. The blades in these industrial turbines are also typically made through investment casting to ensure a long and reliable service life in harsh operating conditions.

For a sourcing manager like Michael, who works for an aerospace supplier, the jet engine application4 is his primary focus. He is responsible for ensuring that the foundries producing these blades meet the absolute highest standards of quality and documentation.

How Is the Quality of a Cast Turbine Blade Ensured?

How do you ensure the quality of a cast turbine blade? What are the key failure modes, and how does the casting process help to prevent them?

Turbine blade quality is analyzed by inspecting for defects and controlling the grain structure. The casting process can create equiaxed, directionally solidified, or single-crystal structures to combat failures like thermal fatigue.

Manufacturing Quality and Failure Analysis of Turbine Blades

Turbine blades are components that push materials science to its limits. Ensuring their integrity is a complex process. For procurement managers, understanding and analyzing suppliers' ability to control casting processes and prevent common failures is of paramount importance.

Common Failure Modes

- Thermal-Mechanical Fatigue: The blade is constantly heated and cooled while being subjected to immense centrifugal forces. This cycling can lead to the formation of cracks.

- Creep: At very high temperatures, the metal can slowly stretch and deform over time under a constant load.

- Oxidation and Corrosion: The hot gas environment is very corrosive.

Preventing Failures Through Controlled Casting

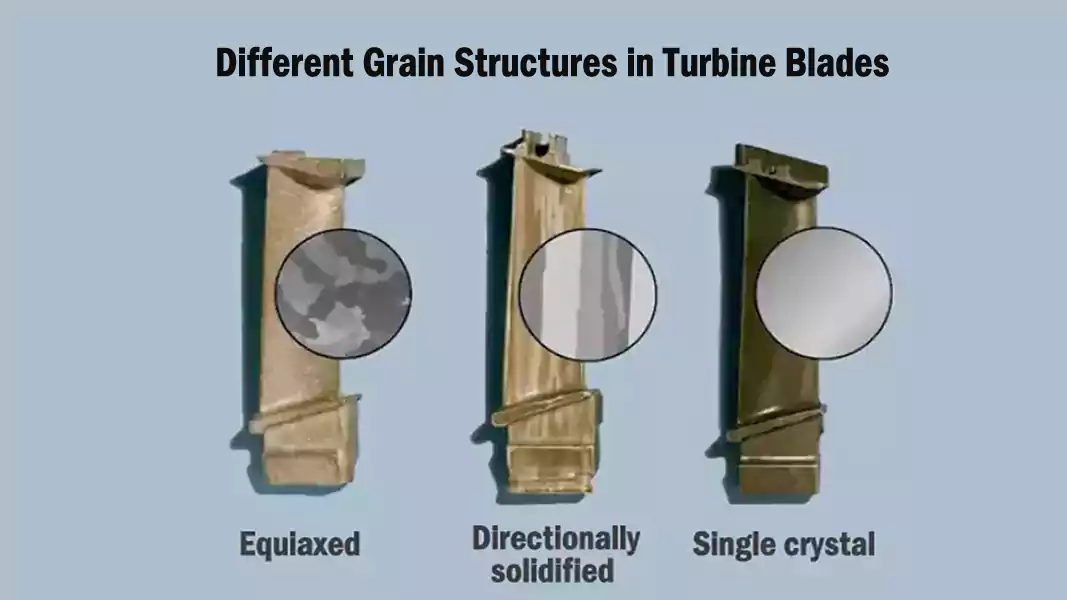

The key to preventing these failures lies in controlling the grain structure of the superalloy during the investment casting process. The boundaries between the microscopic metal grains are the weakest points in the material at high temperatures.

- Equiaxed (EQ) Casting: This is a conventional casting with many small, randomly oriented grains. It has good strength in all directions at lower temperatures.

- Directionally Solidified (DS) Casting: In this advanced process, the casting is cooled very slowly from one end to the other. This creates long, column-like grains that run parallel to the length of the blade. By eliminating the grain boundaries that are perpendicular to the main stress axis, the blade has much better resistance to creep and thermal fatigue.

- Single Crystal (SX) Casting: This is the ultimate casting technology. The process is further refined to create a blade that has no grain boundaries at all—the entire blade is a single, continuous metal crystal. These blades have the highest possible resistance to creep and thermal fatigue and are used in the most demanding applications.

Whether foundries can produce these advanced DS and SX structures is a key indicator of their technical capabilities. For this reason, it is particularly important for purchasing managers to understand these aspects.

Case studies of turbine blade

Below are several examples of turbine blade products we have manufactured:

Case Study 1: Pushing the Limits with Single-Crystal Blades

A major engine client came to us with a tough problem. They were designing a new engine that ran incredibly hot—we're talking gas temperatures over 2100°F. Standard cast blades just wouldn't survive. They could have used more cooling air to keep them from failing, but that would have made the engine less fuel-efficient, defeating the whole purpose.

Our Solution:

This was a perfect job for single-crystal casting. The goal here is to cast the entire blade so it becomes one single metal crystal, with no grain boundaries to weaken it at high temperatures. It's a delicate process. We had to perfectly control the speed at which we pulled the casting from the furnace. Even a tiny deviation could create a flaw and ruin the part. My team and I designed custom fixtures to hold the casting in the perfect orientation as it cooled, ensuring the crystal structure grew exactly as needed.

The Result:

The blades we delivered were a huge success. They operate normally at the target temperature. Because the blades were so much stronger, the client could use less cooling air, which improved the engine's overall fuel efficiency by 3%. It’s a perfect example of how controlling the material’s internal structure at the casting stage leads to real-world performance gains.

Case Study 2: Reviving a Vintage Power Plant Turbine

We got a call from a power plant that was in a real bind. They were running a gas turbine from the 1960s, and a set of blades had failed. The original manufacturer was long gone, and there were no spare parts available anywhere. Their only other option was to have new blades machined from a solid block of metal, which was quoted at over $50,000 per blade—a cost that was just not feasible.

Our Solution:

This is where the flexibility of investment casting really shines. We took one of their old, damaged blades and used a 3D scanner to perfectly capture its geometry, including the complex internal cooling channels. From that scan, we created new tooling for our wax patterns. We analyzed the original metal and cast the new blades in a modern, slightly improved version of the IN-738 superalloy that was still perfectly compatible with the old engine components.

The Result:

We delivered a full set of replacement blades that cost them 60% less than the machined alternative. Because of our modern process controls, the new blades actually performed better than the originals. The plant was back up and running with a more reliable turbine, and they avoided a massive, budget-breaking expense.

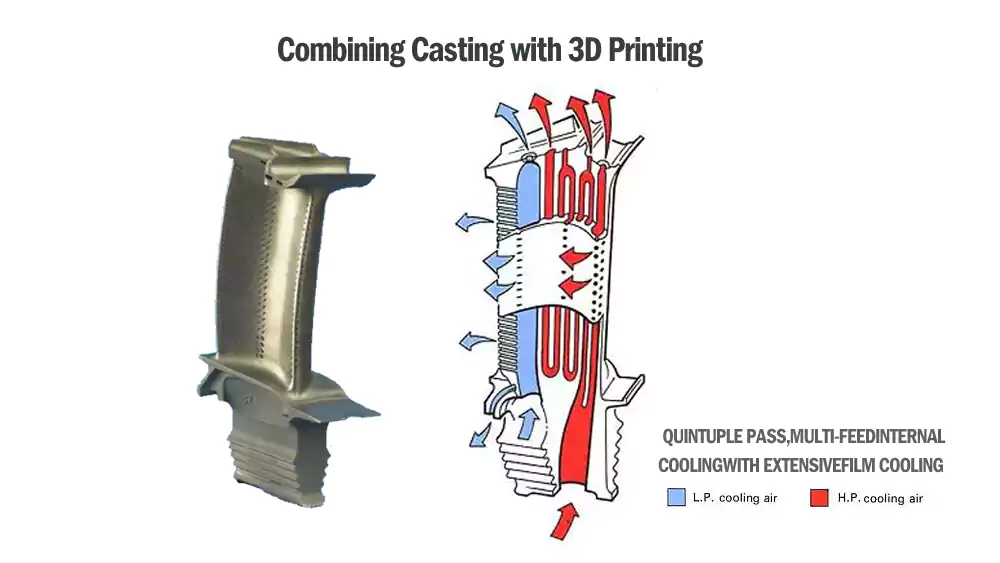

Case Study 3: Combining Casting with 3D Printing

An aircraft engine manufacturer approached us with a forward-thinking idea. They wanted to see if we could combine the strengths of 3D printing and investment casting to create next-generation turbine blades with ultra-complex cooling features.

Our Solution:

We developed a hybrid process. Instead of using traditional ceramic cores to form the cooling passages, we used a specialized 3D printer to create intricate, lattice-like inserts from a refractory material. We then placed these 3D-printed inserts inside our investment casting mold. We cast the blade as usual, and the molten metal flowed around these complex inserts. Afterward, a simple chemical process dissolved the inserts, leaving behind internal cooling channels that are impossible to create with any other method.

The Result:

This hybrid approach gave our client the best of both worlds: the proven material strength and surface finish of an investment cast blade, combined with the geometric freedom of 3D printing. The new cooling design was 25% more efficient at transferring heat, allowing the engine to run hotter and more efficiently. It shows how we're constantly adapting this timeless process to work with the latest technologies.

Conclusion

Investment casting is the essential technology for producing high-performance turbine blades. It uniquely combines the ability to create complex shapes with the metallurgical control needed for extreme environments.If you are sourcing precision parts, choosing a foundry experienced in superalloy casting ensures reliability, efficiency, and long-term performance.

-

Learn about high-temperature superalloys to grasp their significance in extreme environments and their role in turbine blade manufacturing. ↩

-

Understanding Wax Pattern Injection can enhance your knowledge of precision manufacturing techniques used in turbine blade production. ↩

-

Exploring the role of ceramic cores will provide insights into their importance in creating efficient cooling systems in turbine blades. ↩

-

Discover why the jet engine application is critical in aerospace and how it impacts safety and performance. ↩