Need cylindrical metal parts that can withstand extreme stress? Traditional casting methods can leave behind hidden porosity and impurities, leading to part failure under pressure.

Centrifugal casting is a manufacturing process that uses rotational force to distribute molten metal into a mold. This force creates dense, clean, and strong parts with superior mechanical properties.

The first time I worked with centrifugal casting, I noticed how different it was from static casting. The spinning mold seemed almost alive, shaping the part with perfect balance. That impression has stayed with me. I see centrifugal casting as one of the most effective ways to produce high-integrity parts. In this guide, I will explain how it works, the centrifugal casting process steps, types, materials, uses, and advantages, and why it is still one of the best methods today.

How Does Centrifugal Casting Work?

How can spinning a mold create a superior metal part? What is the core principle behind centrifugal casting that makes it so effective at producing dense, clean metal?

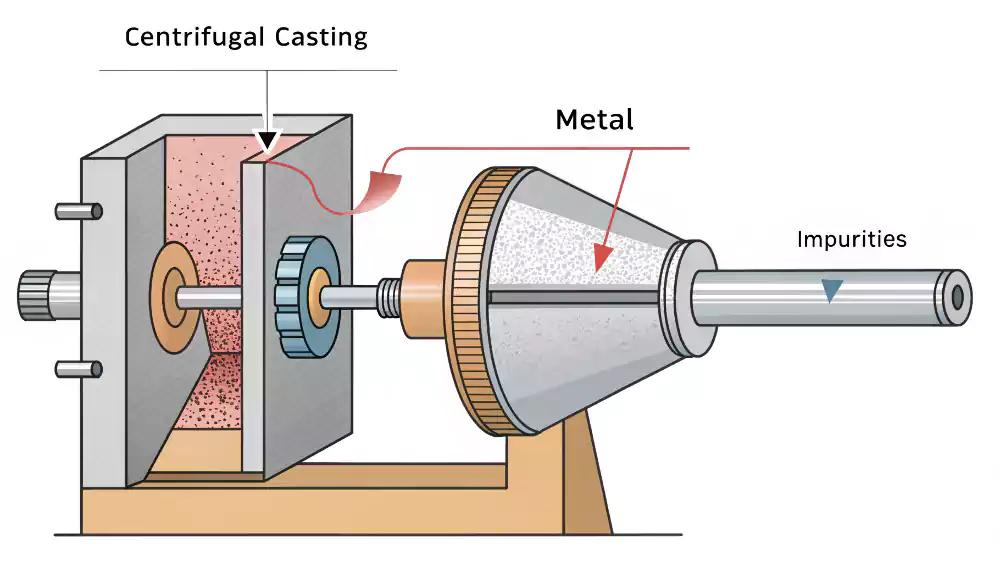

Centrifugal casting works by using G-force from rapid rotation to press molten metal against the mold wall. This pressure forces the metal into the mold's shape, creating a dense, fine-grained part.

Physics Behind the Process

Centrifugal force acts like artificial gravity. It's calculated using rotational speed and mold radius. Higher rotation means greater force on the metal. As a result, this force density gradient causes natural material separation.

Force vs Gravity Comparison

Unlike conventional casting that relies on gravity alone, centrifugal systems generate forces 50–100× stronger.

This table shows key differences:

| Factor | Gravity Casting | Centrifugal Casting |

|---|---|---|

| Force Intensity1 | 1G | 50-100G |

| Porosity | Common | Nearly eliminated |

| Impurity Control | Limited | Concentrated in bore |

| Wall Uniformity | Variable | Highly consistent |

Rotational speed determines final part quality. Too slow causes uneven walls, while too fast risks mold failure. Therefore, we calculate optimal RPM for each project.

Diving Deeper into the Core Principle

The principle behind centrifugal casting is both simple and incredibly powerful. It harnesses the physics of centrifugal force—the same force you feel pushing you outward on a merry-go-round—to improve the quality of cast metal parts.

Here’s how it works:

- Rotation Creates Pressure: A cylindrical mold is rotated at high speed, typically on its own axis. When molten metal is introduced into this spinning mold, the intense rotational force throws the liquid metal against the inner wall. This force can be many times that of gravity (up to 100 Gs).

- Forced, Uniform Solidification: Immense pressure ensures that molten metal distributes evenly and fills every detail of the mold. As it cools, a dense, compact grain structure forms—eliminating most porosity.

- Natural Purification: Centrifugal force separates materials by density, forcing denser metal to the outer wall while impurities migrate inward. After cooling, the impurity-rich inner layer is machined away, leaving only pure, dense metal.

After the casting cools, this inner layer containing all the impurities is simply machined away, leaving behind a part made of only the purest, densest metal. This is why centrifugal casting is known for producing parts with exceptionally high integrity.

What Are the Steps in the Centrifugal Casting Process?

From raw metal to a finished part, what does the workflow look like? What are the key operational steps in a typical centrifugal casting process?

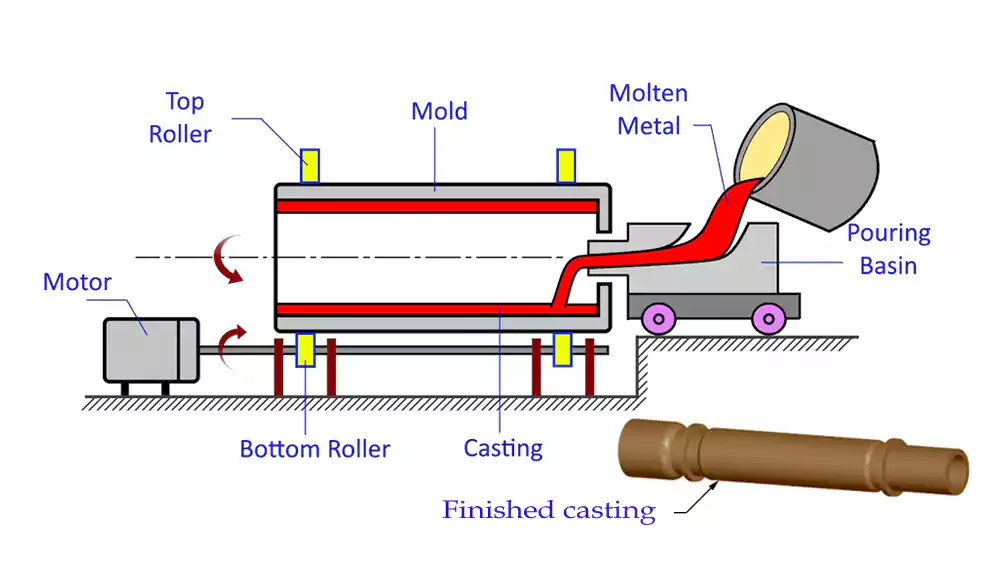

The centrifugal casting process steps involves preparing and preheating the mold, pouring a measured amount of molten metal, spinning the mold at a controlled speed, cooling, and finally, extracting the finished casting.

Diving Deeper into the Production Workflow

A successful centrifugal casting operation is a carefully controlled sequence. Each stage is critical for achieving the part's desired quality and dimensional accuracy.

Here is a typical step-by-step breakdown:

- Mold Preparation and Coating2: Clean, inspect, preheat, and apply ceramic refractory coating to protect the mold and control solidification.

- Pouring the Molten Metal: Pour a pre-measured quantity of molten metal heated to the correct temperature.

- Spinning the Mold: Rotate at a calculated speed to maintain optimal G-force.

- Cooling and Solidification: Maintain spinning during cooling for uniform grain structure.

- Casting Extraction: Remove the solidified part once cooled.

- Finishing: Machine inner and outer diameters to remove impurities and achieve final dimensions.

What Are the 3 Types of Centrifugal Casting?

Are all centrifugally cast parts made the same way? What are the different methods within the centrifugal casting family, and what are they used for?

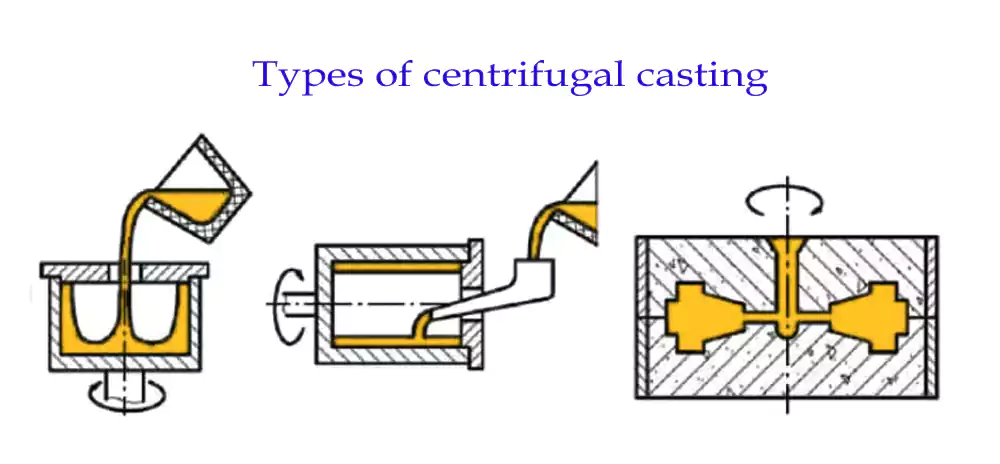

The three types of centrifugal casting are true centrifugal casting for hollow cylinders, semi-centrifugal casting for solid disc shapes, and centrifuging for casting complex shapes off-axis.

Diving Deeper into the Methods

While all three methods use centrifugal force, they are applied differently to produce different types of parts. Understanding these variations helps an engineer like Michael to see the full range of possibilities with this technology.

1. True Centrifugal Casting3

- Process: This is the most common form. A cylindrical mold rotates on its own horizontal or vertical axis. Molten metal is poured in and is thrown to the inside wall, forming a hollow, tube-shaped part. The inner diameter is determined by the amount of metal poured, not by the mold.

- Resulting Shape: Hollow cylinders (tubes, pipes, rings, bushings, liners).

- Key Feature: Produces a naturally hollow part without the need for a central core in the mold. The wall thickness is very uniform. This is the purest form of the process.

2. Semi-Centrifugal Casting4

- Process: The mold is spun on its vertical axis. The shape of the mold is more complex than a simple cylinder, often resembling a disc or wheel. The centrifugal force is used to ensure the molten metal fills the mold cavity completely and produces a dense part. A central core can be used to create a hole.

- Resulting Shape: Solid or hollow discs (wheels, gears, nozzles). The part is symmetrical around the axis of rotation.

- Key Feature: The properties of the metal are best at the outer sections of the part, where the G-force is highest.

3. Centrifuging (or Centrifuge Casting)

- Process: In this method, several individual molds are arranged in a symmetrical pattern around a central sprue. The entire assembly is then spun on a vertical axis. The centrifugal force acts like a pressure pump, forcing the molten metal from the central sprue out into each of the mold cavities.

- Resulting Shape: A cluster of smaller, often complex and non-symmetrical parts.

- Key Feature: This method doesn't use the force to shape the part itself, but rather to ensure the molds are filled with very clean, dense metal under high pressure. This results in high-quality castings with fine detail.

Which Metals Can Be Centrifugally Cast?

Is this process limited to certain materials? What common engineering metals and alloys are suitable for the centrifugal casting process?

Centrifugal casting materials include iron, steel, stainless steel, nickel alloys, aluminum alloys, and copper alloys (bronze, brass). This versatility supports a wide range of industrial applications.

Diving Deeper into Material Compatibility

One of the great strengths of centrifugal casting is its compatibility with a vast range of metals and alloys. The process is less sensitive to alloy composition than some other casting methods. This gives an engineer like Michael a great deal of flexibility in choosing a material that has the exact properties needed for his application.

Here are some of the most common materials used:

- Iron: Both gray iron and ductile iron are commonly cast using this method to produce parts like pipes, cylinder liners, and rollers.

- Steel: A wide variety of carbon, low-alloy, and high-alloy steels are used. The process produces a clean, dense structure that is ideal for high-strength steel components.

- Stainless Steel: Many grades of stainless steel are centrifugally cast to create parts for corrosive environments, such as components for the chemical processing, marine, and food industries. The process ensures a dense, porosity-free structure that maximizes corrosion resistance.

- Nickel Alloys: High-performance nickel alloys (like Inconel and Monel) are used for applications in extreme temperature or highly corrosive environments, such as in the aerospace and energy sectors. Centrifugal casting is an ideal method for these expensive and critical alloys.

- Copper Alloys (Bronze and Brass): Bronze alloys are very frequently centrifugally cast to produce high-quality bushings, bearings, and gear blanks. The process creates a superior wear-resistant surface.

- Aluminum Alloys: While less common than for ferrous metals, aluminum alloys can be centrifugally cast to produce high-integrity components for aerospace and automotive applications.

This versatility allows us to produce parts with the specific mechanical, thermal, and corrosion properties that a project demands.

What Is Centrifugal Casting Used For?

Where are these high-integrity parts used in the real world? What are some common applications for components made through centrifugal casting?

Centrifugal casting is used for critical, high-performance cylindrical parts like pipes, tubes, bushings, bearings, rollers, and engine cylinder liners in the aerospace, industrial, and energy sectors.

Diving Deeper into Real-World Applications

The unique benefits of centrifugal casting—high density, purity, and strength—make it the preferred manufacturing method for a wide range of critical components. These are parts where reliability is non-negotiable.

Here are some of the most common applications that a sourcing manager like Michael would encounter:

- Pipes and Tubes: Seamless pipes for the oil and gas, chemical processing, and power generation industries are often made with centrifugal casting. The process creates a very strong, uniform wall that can withstand high pressures and corrosive environments.

- Bushings and Bearings: Bronze and other copper alloys are centrifugally cast to create high-quality bushings and bearings. The dense, fine-grained structure provides excellent wear resistance5 and a low coefficient of friction, which is ideal for rotating machinery.

- Engine Cylinder Liners: The liners inside engine cylinders for large diesel engines (in ships, trucks, and locomotives) are made using this process. The resulting part is extremely durable and can withstand the intense heat and pressure of combustion.

- Rollers and Rings: Large rollers for steel mills, paper mills, and printing presses are centrifugally cast to ensure they are perfectly balanced and have a very durable, wear-resistant surface. Large-diameter rings for jet engines and bearings are also made this way.

- Aerospace Components: The aerospace industry uses centrifugal casting for various high-performance parts, including jet engine compressor cases, rings, and other cylindrical components made from nickel alloys and high-strength steels.

In all these applications, the parts are subjected to intense stress, wear, or corrosive environments. Centrifugal casting is chosen because it produces a component with the integrity to perform reliably under these conditions.

What are the advantages and disadvantages of Centrifugal Casting?

No process is perfect for every job. What are the key pros and cons of centrifugal casting compared to other manufacturing methods like forging or sand casting?

The main advantages are high material density, low porosity, and excellent mechanical properties. The primary disadvantages are its limitation to mostly cylindrical shapes and higher initial tooling costs.

Diving Deeper into the Pros and Cons

For a manager like Michael, who has to balance performance, cost, and lead time, understanding the trade-offs of a manufacturing process is essential. Centrifugal casting has a very clear set of advantages and disadvantages.

| Advantages | Disadvantages |

|---|---|

| Superior Part Quality: The castings are extremely dense and have very low porosity. The natural purification process removes impurities, resulting in a clean, high-integrity part. | Shape Limitations: The process is best suited for producing parts that are symmetrical around an axis of rotation (cylindrical or disc-shaped). It cannot be used for complex, asymmetrical geometries. |

| Excellent Mechanical Properties: The fine-grained, dense structure results in parts with superior tensile strength, toughness, and wear resistance compared to static castings. | Higher Tooling Costs: The reusable metal molds (dies) are expensive to manufacture compared to the disposable sand molds used in sand casting. This makes the process less economical for very small quantities or one-off parts. |

| Near-Net-Shape Capability: The process produces parts with uniform wall thickness and good dimensional accuracy. This reduces the amount of secondary machining required, saving time and material. | Inner Diameter is Not Formed: In true centrifugal casting, the inner diameter is not shaped by a mold but is the result of the amount of metal poured. This means the ID must always be machined to its final size. |

| Versatility with Materials: As we've discussed, it is suitable for a very wide range of metals and alloys. | Not Suitable for All Sizes: While great for a wide range, there are practical limits on the very small or extremely large parts that can be produced. |

My experience shows that when a design calls for a high-performance cylindrical part, the metallurgical advantages of centrifugal casting often far outweigh its geometric limitations. It is the best way to make a superior quality tube, ring, or bushing.

Why Does Centrifugal Casting Stand Out in Modern Manufacturing?

With so many advanced manufacturing technologies available, why is this century-old process still so critical? What makes centrifugal casting stand out as a modern, high-performance method?

Centrifugal casting stands out because it delivers what modern industries demand most: high reliability and performance. Its ability to create dense, defect-free parts in high-strength alloys is essential for critical applications.

Diving Deeper into its Modern Relevance

In an era of 3D printing and advanced CNC machining, it's easy to overlook a process like centrifugal casting. However, it remains a vital and indispensable part of modern manufacturing, especially for high-stakes industries like aerospace and energy. For a sourcing manager like Michael, its relevance is clearer than ever.

Here’s why it stands out:

-

Unmatched Material Integrity: The core benefit is the quality of the metal itself. The combination of high pressure and directional solidification creates a part that is metallurgically superior to what can be achieved with static casting. As I mentioned, the process naturally cleanses the metal, pushing impurities to the center where they are removed. This results in a finished product with a proven, reliable internal structure.

-

Efficiency and Reduced Waste (Near-Net-Shape): The process is highly efficient. It produces parts that are very close to their final dimensions, which significantly reduces the amount of material that needs to be machined away. Less machining means shorter lead times, lower costs, and less waste, which are all key priorities for modern supply chains.

-

Consistency and Repeatability: The use of robust, reusable molds and a controlled process means that centrifugal casting can produce thousands of parts with highly consistent quality. For a quality manager, this repeatability is essential for validating a process and ensuring a reliable supply of components.

-

Enables High-Performance Alloys: The process works exceptionally well with the high-strength steels, nickel alloys, and bronzes that are required for today's most demanding applications. It provides a reliable way to cast these advanced materials into strong, defect-free components.

It’s not the most flexible process, but for the parts it is designed to make—high-performance cylinders and rings—centrifugal casting consistently delivers a level of quality that is difficult and expensive to achieve by any other method.

What Are Some Common FAQs About Centrifugal Casting?

When I discuss centrifugal casting with clients like Michael, who are deeply focused on material properties and quality, a few specific questions often arise. Here are some quick answers.

Q1: Is centrifugal casting expensive?

A: The equipment cost is high, but part costs are competitive due to low waste and reduced machining.

Q2: How accurate is centrifugal casting?

A: Dimensional accuracy is high, especially for cylindrical parts, often reducing or eliminating post-machining.

Q3: Can it handle large parts?

A: Yes, but there are limits based on mold size and machine capacity.

Q4: Does it work with titanium?

A: Yes, but it requires special handling and inert atmospheres to prevent contamination.

Q5: How does centrifugal casting compare to forging?

This is a great question, as both are used to make high-strength parts.

- Forging works a solid piece of metal, aligning its grain structure to the shape of the part. This generally produces the highest possible strength and impact toughness. However, it is limited to simpler shapes.

- Centrifugal casting starts with liquid metal. While its directional solidification creates a very strong, fine-grained structure, it typically does not achieve the same level of tensile strength as a forging. However, centrifugal casting can create much more complex hollow shapes (like a tube with a special outer profile) that would be impossible to forge.

Q6: What is the typical as-cast surface finish?

The as-cast surface finish depends on the quality of the mold coating, but it is generally rougher than other casting methods.

- Outer Diameter: A typical as-cast finish on the OD is around 250-500 RMS.

- Inner Diameter: The as-cast ID surface is rougher due to the impurities that collect there.

It's important to remember that all functional surfaces of a centrifugal casting are intended to be machined to their final dimension and finish.

Conclusion

Centrifugal casting is a superior process for creating high-integrity, cylindrical metal parts. Its use of rotational force produces dense, clean components essential for high-performance industrial and aerospace applications.

If you’re looking for high-integrity cylindrical parts, centrifugal casting remains one of the most reliable and efficient manufacturing methods available today. Contact us to learn how we can help with your project.

-

Learn how Force Intensity impacts casting quality, ensuring better results in manufacturing processes. ↩

-

Exploring mold preparation techniques can significantly impact the quality of your cast parts and optimize production efficiency. ↩

-

Explore this link to understand the fundamentals and applications of True Centrifugal Casting, enhancing your knowledge of casting methods. ↩

-

Discover the benefits of Semi-Centrifugal Casting, which can help you appreciate its unique properties and applications in manufacturing. ↩

-

Discover the significance of wear resistance in materials to ensure longevity and performance in machinery and components. ↩