Your CNC machine is only as good as its spindle. Without it, you're just moving metal around. I learned this early in my machining career when a worn spindle ruined a critical aerospace part.

A CNC spindle is the rotating component that holds and drives cutting tools. It provides the rotational force (RPM) and torque needed for material removal. Precision bearings allow high-speed rotation while maintaining tool position accuracy for consistent machining results.

Every CNC machinist I know starts by learning the controller or G-code. But it didn’t take long for me to realize that the real heartbeat of the machine is the spindle. Once I understood how it works and how to select the right one, my parts got better, my tools lasted longer, and my shop ran smoother.

What is a spindle on a CNC machine and how does it work?

Spindle failure stops production dead. I recall losing $8,000 in downtime when one seized during a rush order. Never again.

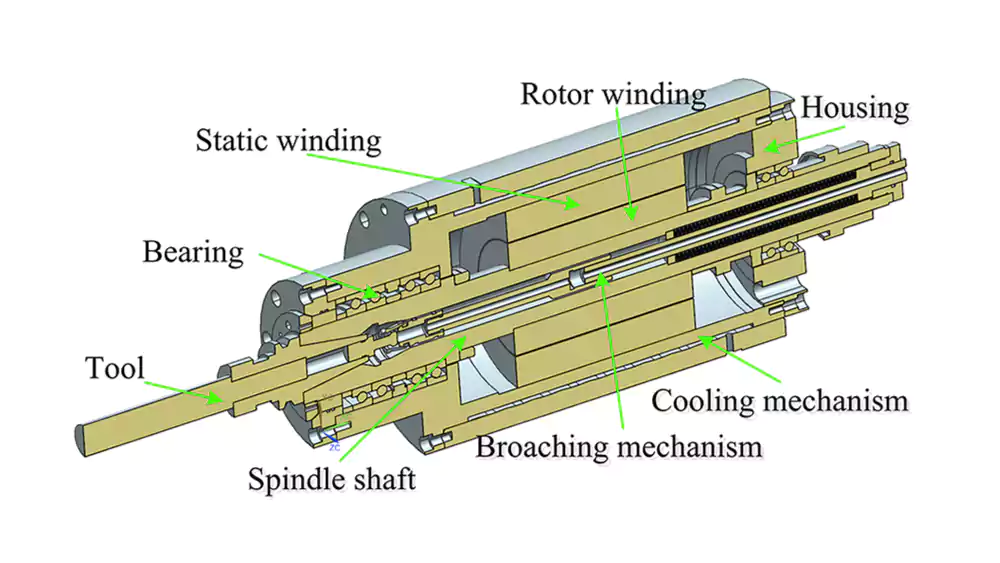

The spindle assembly houses a motor-driven shaft that rotates cutting tools. Electric or belt-driven motors generate rotation, while precision bearings minimize vibration. Tool holders attach via standardized tapers (like CAT or BT) ensuring secure, accurate mounting during operation.

Core Components

-

Motor Types1: Direct Drive Belt-Driven Higher RPM More torque Less maintenance Lower cost -

Bearing Systems2: Angular Contact Hydrostatic Common in most machines For ultra-high precision Requires lubrication Oil-film supported Cost-effective Minimal vibration

Operational Workflow

Power transfers from the motor to the tool holder. Coolant flows through internal channels to prevent overheating at high speeds. Encoders monitor real-time RPM, automatically adjusting to maintain set speeds. Vibration sensors detect imbalance, shutting down before damage occurs. This integrated system maintains precision during 20+ hour machining cycles.

What is the purpose of a CNC spindle?

I once machined aluminum parts with a wood router spindle. The chatter marks looked like a beaver chewed them. Proper spindles prevent this.

The spindle's core purpose is converting power into controlled tool rotation. It positions tools accurately, applies cutting forces consistently, and maintains programmed speeds under load. This directly impacts part quality and machining efficiency.

Critical Functions

- Speed Control: Maintains RPM during variable cutting loads

- Torque Delivery3: Provides consistent power for tough materials

- Tool Positioning: Holds tools within 0.0001" tolerance

- Vibration Management: Absorbs cutting forces through rigid construction

What are the types of CNC spindles?

Choosing the wrong spindle can slow you down, waste tools, and even ruin parts. That’s why I always match the spindle type to the job.

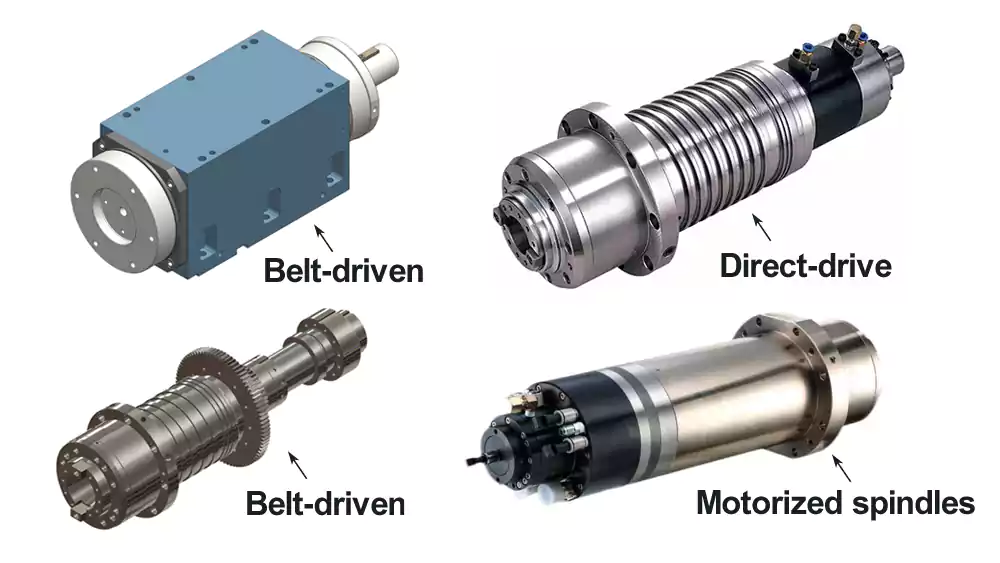

The main types of CNC spindles include belt-driven, direct-drive, gear-driven, and motorized spindles. Each offers different advantages depending on torque, speed, and precision needs.

Belt-Driven Spindles

These use pulleys and belts to transfer power from the motor to the spindle. I’ve used belt-driven spindles in many general-purpose jobs. They’re simple and affordable, and belts can absorb vibration, which helps with tool life.

| Feature | Belt-Driven Spindles |

|---|---|

| Speed Range | 100–8,000 RPM |

| Torque | Moderate |

| Maintenance | Easy (belt replacement) |

| Best Use | General machining, job shops |

The downside is belt wear and slippage4. Over time, belts stretch and lose tension. This affects speed accuracy and can cause poor surface finish. I check belt tension monthly in older machines.

Direct-Drive Spindles

These connect the motor directly to the spindle shaft. No belts, no gears—just pure motion. These are my go-to for precision jobs.

| Feature | Direct-Drive Spindles |

|---|---|

| Speed Range | Up to 60,000 RPM |

| Torque | Low to moderate |

| Maintenance | Low |

| Best Use | High-precision, high-speed milling |

Direct drives are more expensive, but the lack of backlash and the speed response are unbeatable. If I’m running tight-tolerance parts or micro-milling, I always choose a direct-drive setup.

Gear-Driven Spindles

Gear-driven spindles use mechanical gears to boost torque at low speeds. I use them for heavy cuts, large parts, and tough materials.

| Feature | Gear-Driven Spindles |

|---|---|

| Speed Range | Up to 3,000 RPM |

| Torque | High |

| Maintenance | Moderate (gear wear) |

| Best Use | Heavy-duty machining, steel, cast iron |

Gearboxes do add complexity and noise, but they’re worth it for torque-intensive work. I’ve used them for parts with deep cavities and roughing passes in tool steels where smaller spindles would stall.

Motorized Spindles

These are compact spindles with the motor built directly into the spindle housing. I’ve used motorized spindles when space is tight or when I need precise speed control without external belts or gearboxes.

| Feature | Motorized Spindles |

|---|---|

| Speed Range | 6,000–50,000 RPM |

| Torque | Moderate |

| Maintenance | Low |

| Best Use | Compact machines, high-speed and precision applications |

Motorized spindles are quieter and more efficient since there’s no power loss through belts or gears. They’re also easier to integrate with automation systems. When I use them for fine-detail milling or engraving, the results are consistently smooth and accurate. The internal cooling system—usually air or liquid—prevents overheating during long cycles. However, these spindles are more expensive to replace or repair, and not ideal for heavy roughing. I recommend them for high-speed, light-duty operations where precision matters most.

What are the Advantages of CNC Spindles?

After upgrading our VMC spindles, part output jumped 40%. The ROI surprised even me.

Modern spindles enable faster machining, tighter tolerances, and superior surface finishes. They reduce setup times through automatic tool changing and allow adaptive machining strategies. This cuts production costs while improving quality consistency.

Key Benefits

- Speed Flexibility: One spindle handles multiple operations

- Precision Holding: < 0.0003" runout for fine details

- Reduced Vibration: Allows aggressive material removal rates

- Thermal Stability: Maintains accuracy during long cycles

How Do Spindles Affect Machining Accuracy and Surface Finish?

A 0.001" spindle deflection ruined 300 medical implant housings. Now we monitor spindle health religiously.

Spindle condition directly determines part quality. Runout causes dimensional errors. Vibration creates surface waves. Thermal growth shifts tool position. Balanced spindles with precision bearings produce mirror finishes and hold micron-level tolerances.

Critical Relationships

| Spindle Factor | Accuracy Effect | Surface Impact |

|---|---|---|

| Runout | Hole size errors | Tool marks |

| Vibration | Feature drift | Chatter marks |

| Thermal growth | Position shift | Inconsistent finish |

| Bearing wear | Reduced rigidity | Rough patches |

Maintenance Essentials

- Daily: Check lubrication levels

- Weekly: Measure runout with test bar

- Monthly: Flush coolant passages

- Quarterly: Replace air filters

- Annually: Professional recalibration

How to Choose the Right Spindle for Manufacturing?

If you were buying a CNC machine or evaluating a supplier, how would you choose? What key spindle characteristics should you look for based on your manufacturing needs?

Choose a spindle based on your primary application. Consider the required speed (RPM) for your materials, the torque needed for your type of cutting, and the tool interface (e.g., HSK) for precision.

Diving Deeper into Spindle Selection Criteria

Choosing the right CNC spindle—either when purchasing a new machine or when selecting a manufacturing partner—is about matching the spindle's capabilities to the work you need to do. A shop that specializes in heavy steel cutting will have very different spindles than a shop that makes small aluminum medical parts. For David, understanding these trade-offs is key to vetting a supplier's capabilities.

Here are the key factors to consider:

-

Speed (Maximum RPM):

- Question: What materials will you be cutting most often?

- Consideration: If you primarily machine aluminum, composites, or use small-diameter tools, you need a high-speed spindle (e.g., 15,000 RPM or higher) to achieve the necessary surface speeds for efficient cutting. If you mostly machine tough steels or titanium, ultra-high speeds are less critical.

-

Torque (Cutting Power):

- Question: Will you be doing heavy roughing or light finishing?

- Consideration: If your work involves removing large amounts of material with big tools (heavy roughing), you need a high-torque spindle. Belt-driven or geared spindles often excel here, providing a lot of power at lower RPMs. If your work is primarily light-duty finishing, high torque is less important than speed and smoothness.

-

Tool Holder Taper:

- Question: What level of precision and speed do you require?

- Consideration: For general-purpose work, standard CAT40 or BT40 spindles are robust and reliable. For high-speed, high-precision finishing operations, a more advanced HSK interface is superior due to its higher rigidity and better balance.

-

Cooling System:

- Question: Will you be running long production cycles?

- Consideration: For long runs, especially at high speeds, a liquid-cooled spindle is essential for maintaining thermal stability and consistent accuracy. For very light or intermittent work, a simpler air-cooled spindle might suffice.

By evaluating these four key areas, you can determine if a specific CNC spindle is properly equipped to handle your manufacturing requirements efficiently and accurately.

Conclusion

The CNC spindle drives speed, power, and precision. Its quality directly shapes your results—choose and maintain it well to ensure better parts, faster output, and lasting competitiveness.

-

Understanding motor types is crucial for selecting the right equipment for efficiency and performance. ↩

-

Exploring bearing systems can enhance your knowledge of precision and reliability in machining operations. ↩

-

Understanding Torque Delivery is crucial for optimizing machining processes and ensuring consistent power for tough materials. ↩

-

Learn effective strategies to minimize belt wear and slippage, ensuring optimal performance and longevity of your equipment. ↩