Need intricate metal parts with tight tolerances but unsure which casting method fits? Choosing incorrectly means costly errors, poor performance, and project delays for critical components.

Precision investment casting uses a disposable wax pattern to create a ceramic mold. Molten metal is poured in, yielding highly detailed, complex metal parts with excellent surface finish and accuracy.

My journey in metal manufacturing started on the shop floor of an investment casting facility. That experience gave me a deep appreciation for the artistry and engineering that goes into this process.

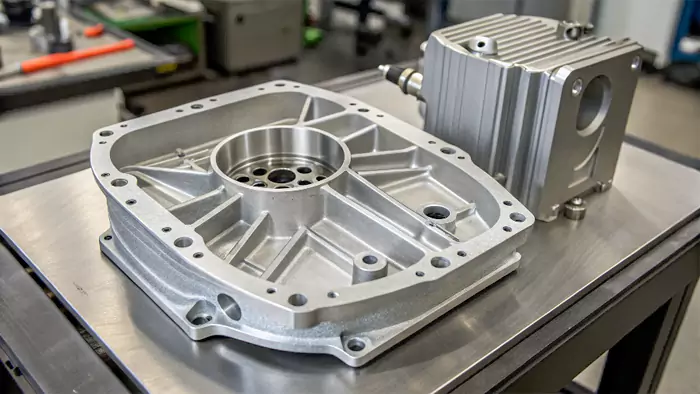

Now, as the founder of Allied Metal, where we deliver high-precision investment casting solutions alongside 3D printing and rapid prototyping, I often share my insights with people like Michael, who manage sourcing and quality for demanding sectors. My core belief is that precision investment casting is a process where you make super detailed metal parts by pouring molten metal into a mold made from a wax pattern. It’s not just another casting method; it’s perfect when you need complex shapes, smooth surfaces, and tight tolerances—like for aerospace or medical components. Understanding this process is key to unlocking its potential for challenging projects.

Precision or Investment Casting: Are They One and the Same?

You hear "precision casting" and "investment casting" used. Are these terms interchangeable, or do they describe different manufacturing approaches for metal parts?

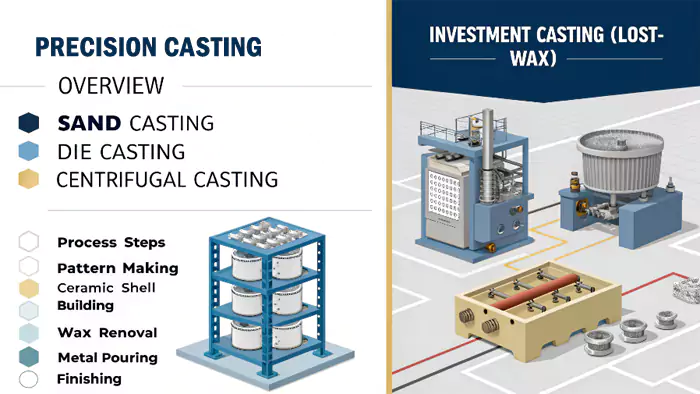

Investment casting is a specific type of precision casting. "Precision casting" is a broader term for methods yielding high accuracy; investment casting is one such advanced technique.

Diving Deeper into the Terminology

It's common for terms in manufacturing to overlap or be used in ways that can cause a bit of confusion. Let's clarify "precision casting" and "investment casting" for sourcing managers like Michael, who need to be exact with their specifications.

"Precision casting" is a general, overarching term. It refers to any casting process that is capable of producing parts with:

- High dimensional accuracy (tight tolerances).

- Intricate details and complex geometries.

- A good surface finish, often reducing the need for extensive secondary machining.

The goal of any precision casting method is to create components that are as close to their final desired shape and dimensions (near-net shape) as possible, directly from the casting process.

"Investment casting," on the other hand, is a specific manufacturing process that falls under the umbrella of precision casting. It's also historically known as the "lost-wax process." It achieves its high precision and ability to create complex shapes through a unique mold-making technique:

- A pattern of the desired part is made from wax or a similar material that can be melted or burned out.

- This pattern is then "invested" – meaning it's coated with layers of a ceramic slurry that hardens to form a one-piece mold.

- The wax pattern is melted out of this ceramic shell, leaving a precise cavity.

- Molten metal is poured into the preheated ceramic mold.

- Once the metal solidifies, the ceramic shell is broken away to reveal the cast part.

So, while all investment casting is a form of precision casting, not all precision casting is investment casting. Investment casting is renowned for being one of the most precise casting methods, capable of producing exceptionally detailed and complex parts, which aligns perfectly with my insight about making "super detailed metal parts."

What Truly Defines a 'Precision Casting'?

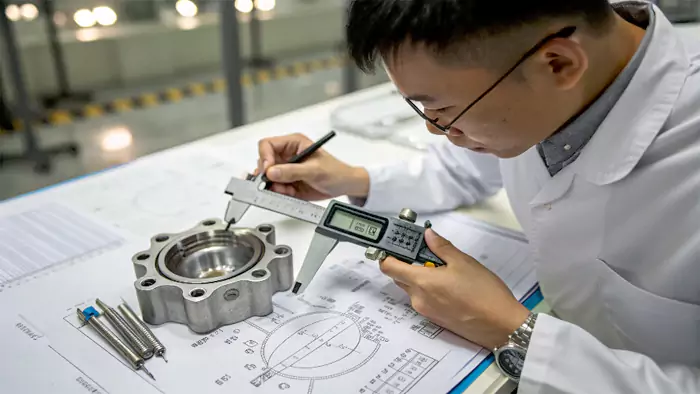

We know investment casting is a type of precision casting. But what are the core characteristics or goals that generally define any "precision casting" method?

A precision casting is characterized by its ability to produce parts with tight dimensional tolerances, intricate designs, excellent surface finishes, and minimal need for subsequent machining operations.

Diving Deeper into the Hallmarks of Precision Casting

The term "precision casting" isn't just a marketing buzzword; it signifies a class of casting processes engineered to deliver a higher level of quality and accuracy compared to conventional methods like basic sand casting. For a Sourcing and Quality Manager like Michael, understanding what defines a precision casting is crucial for setting expectations and specifying requirements.

The defining goals and characteristics of any precision casting process include:

-

High Dimensional Accuracy & Tight Tolerances1:

- This is paramount. Precision castings are expected to conform closely to the specified dimensions and geometric tolerances laid out in the engineering drawings. This minimizes variations between parts and ensures proper fit and function in assemblies. My insight about investment casting being perfect for "tight tolerances" applies broadly to all precision casting goals.

-

Capability for Complex Geometries & Intricate Details:

- These processes must be able to reproduce complex shapes, thin walls, internal cavities, fine details, and undercuts that might be difficult or impossible to achieve with other manufacturing methods without extensive secondary work. Investment casting excels here, but other precision methods also aim for this.

-

Good to Excellent Surface Finish:

- Precision castings typically yield a much smoother surface finish than conventional casting methods. This can reduce or even eliminate the need for secondary surface finishing operations like grinding or extensive polishing, saving time and cost.

-

Near-Net Shape or Net-Shape Parts2:

- The ideal precision casting produces a part that is very close to its final required shape (near-net shape) or, in some cases, exactly to the final shape (net-shape), requiring little to no subsequent machining. This reduces material waste and downstream processing costs.

-

Consistency and Repeatability:

- For production runs, a precision casting process must be able to consistently produce parts that meet the required specifications batch after batch.

While investment casting is a prime example of a process that achieves these characteristics, other methods like die casting (for certain materials and complexities), shell molding, or even some advanced permanent mold techniques can also be considered forms of precision casting when they deliver parts meeting these high standards. The choice of which precision casting method to use depends on factors like the alloy, part size, complexity, production volume, and specific tolerance requirements.

Unpacking the Term: What Is the Real Meaning Behind 'Investment Casting'?

The term "investment casting" is unique. What does "investment" refer to in this context, and how does this meaning relate to the process and its capabilities?

In "investment casting," the term "investment" refers to the process of covering or enveloping a disposable wax pattern with a refractory ceramic material to create the mold shell.

Diving Deeper into the "Investment" in Investment Casting

The name "investment casting" might sound like it refers to a financial investment, but in this manufacturing context, the word "investment" has a more traditional, technical meaning. It comes from the verb "to invest," which in an older sense means to clothe, cover, or surround something completely. This perfectly describes a key step in the process.

The "Investment" Step:

The core of the investment casting process, and where it gets its name, is the creation of the ceramic mold around a disposable pattern, which is almost always made of wax.

- Wax Pattern: First, an exact replica of the desired part is created in wax.

- Slurry Coating: This wax pattern (or an assembly of patterns called a "tree") is then repeatedly dipped into a bath of refractory ceramic slurry3. A refractory material is one that can withstand very high temperatures without degrading.

- Stuccoing: After each dip in the slurry, the wet pattern is "stuccoed" with fine ceramic sand or particles. This helps build up the thickness and strength of the shell.

- Drying: Each layer of ceramic is allowed to thoroughly dry and harden.

This process of dipping and stuccoing is repeated multiple times, building a robust, multi-layered ceramic shell that completely encases or "invests" the wax pattern.

The "Lost-Wax" Connection:

Once the ceramic shell is complete and dried, the wax pattern inside is melted or burned out in an oven or autoclave. This leaves a hollow cavity within the ceramic shell that is an exact negative of the original wax pattern. This is why the process is also famously known as the "lost-wax" method.

Why This Matters for Precision:

This method of creating a one-piece, seamless ceramic mold directly from a highly detailed wax pattern is what allows investment casting to produce parts with:

- Exceptional Detail and Complexity: The wax can be molded into very intricate shapes, and the ceramic faithfully captures these details. My insight about it being "perfect when you need complex shapes" stems directly from this.

- Smooth Surface Finishes: The fine ceramic materials used for the initial coats result in a very smooth mold cavity, leading to castings with excellent surface quality.

- Tight Tolerances: The dimensional stability of the ceramic shell and the precision of the wax pattern contribute to the high accuracy of the final metal parts.

For Michael, sourcing aerospace components where precision is non-negotiable, understanding that the "investment" step is central to achieving these qualities is key to appreciating the process's value.

Beyond Investment Casting: What Are Four Main Types of Metal Casting Processes?

Investment casting is a specialized technique. How does it fit into the broader world of metal casting? What other major casting methods are commonly used in manufacturing?

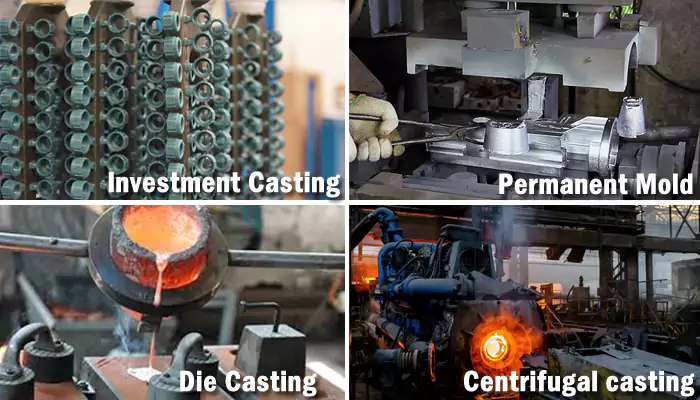

Four main casting types include: 1) Expendable Mold (e.g., sand, investment), 2) Permanent Mold, 3) Die Casting (high-pressure permanent mold), and 4) Centrifugal Casting, each with unique applications.

Diving Deeper into Major Metal Casting Categories

Metal casting is a vast field with many different processes, each suited to different materials, part sizes, complexities, production volumes, and cost considerations. While investment casting is a star player for precision, it's helpful for a Sourcing and Quality Manager like Michael to understand how it compares to other main categories. Here are four broad types:

-

Expendable Mold Casting:

- Principle: Uses a temporary mold that is destroyed to remove the casting. The mold material is typically sand, ceramic (as in investment casting), or plaster.

- Sub-types:

- Sand Casting: Molten metal is poured into a mold made of compacted sand.

- Pros: Versatile for many metals, low tooling cost, good for large parts, complex shapes possible.

- Cons: Rougher surface finish, looser tolerances, more machining often required.

- Investment Casting: (As discussed extensively)

- Pros: Excellent detail, complex shapes, tight tolerances, smooth finish.

- Cons: Higher cost per part than sand casting, longer lead times for tooling and process.

- Shell Molding: A resin-coated sand is used to create a thin, hardened shell mold. Better finish and accuracy than conventional sand casting.

- Sand Casting: Molten metal is poured into a mold made of compacted sand.

- Common For: Engine blocks (sand), turbine blades (investment), valve bodies (shell).

-

Permanent Mold Casting (Gravity and Low-Pressure):

- Principle: Uses reusable molds, typically made from metal (e.g., steel, cast iron). Molten metal is usually poured under gravity or low pressure.

- Pros: Better dimensional accuracy and surface finish than sand casting, reusable mold leads to lower per-part cost in higher volumes, faster cycle times than expendable mold processes.

- Cons: Higher initial mold cost than sand casting patterns, limited to simpler shapes compared to investment casting, primarily for lower melting point alloys like aluminum, magnesium, and copper alloys.

- Common For: Automotive pistons, cylinder heads, pump housings.

-

Die Casting (High-Pressure Die Casting):

- Principle: A type of permanent mold casting where molten metal is forced into a steel die (mold) under high pressure and at high speed.

- Pros: Excellent dimensional accuracy, very smooth surface finish, ability to produce thin walls and complex details, very fast cycle times for high-volume production.

- Cons: Very high tooling (die) costs, generally limited to non-ferrous, lower melting point alloys (zinc, aluminum, magnesium), less suitable for very complex internal features than investment casting.

- Common For: Automotive components, appliance housings, hardware, electronic enclosures.

-

Centrifugal Casting:

- Principle: Molten metal is poured into a rapidly rotating mold. Centrifugal force distributes the metal, creating a dense, fine-grained casting.

- Pros: Produces parts with high density and purity, good mechanical properties. Can create cylindrical shapes with hollow interiors without cores.

- Cons: Shape limitations (mainly cylindrical or tubular), specialized equipment needed.

- Common For: Pipes, tubes, bushings, rings, cylinder liners.

Understanding this landscape helps engineers make informed decisions about which casting process is most appropriate when sourcing parts, considering the specific requirements of his aerospace components versus what other methods offer. Investment casting clearly stands out for its ability to deliver complex, high-precision parts, justifying its cost for critical applications.

Conclusion

Precision investment casting creates intricate, detailed metal parts with smooth finishes and tight tolerances. It’s ideal for complex designs where accuracy and quality are paramount.

-

Learn why these characteristics are critical in manufacturing, ensuring quality and performance in your projects. ↩

-

Discover the significance of near-net and net-shape parts in reducing waste and improving efficiency in manufacturing processes. ↩

-

Understanding refractory ceramic slurry is crucial for grasping its role in high-temperature applications and manufacturing processes. ↩