Precision CNC Machining Services

From rapid prototyping to mass production – Your trusted partner for high-precision CNC machining, investment casting, and surface finishing solutions

Why Choose CNC Machining?

Discover the unmatched advantages of precision CNC machining for your manufacturing needs

Unmatched Precision

Achieve tolerances as tight as ±0.005mm with our advanced CNC technology. Perfect for critical components requiring exact specifications.

Consistent Repeatability

Automated processes ensure identical parts every time, eliminating human error and maintaining quality across large production runs.

Complex Geometries

Create intricate designs impossible with traditional machining. Our 5-axis capabilities handle the most challenging geometries.

Rapid Turnaround

From CAD to finished part in days, not weeks. Our streamlined process reduces lead times by up to 60%.

Cost Effective

Eliminate expensive tooling costs and reduce waste. Perfect for both prototyping and medium-volume production.

Material Versatility

Machine virtually any material - from aluminum and steel to exotic alloys and engineering plastics.

Common Types of CNC Machining Processes

CNC machining encompasses various operations, including CNC milling, CNC turning, CNC grinding, and CNC drilling, among others, each tailored to different manufacturing needs and requirements.

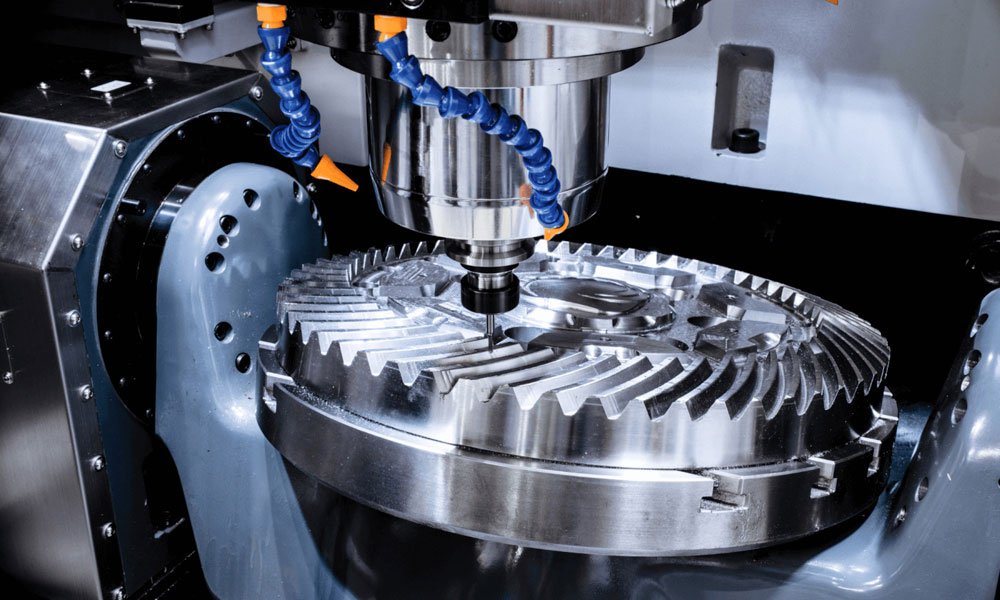

CNC Milling

CNC milling uses rotating multi-point cutting tools to remove material and create complex shapes. It handles operations like drilling, slotting, and contouring, suitable for prototypes and high-volume production with tight tolerances.

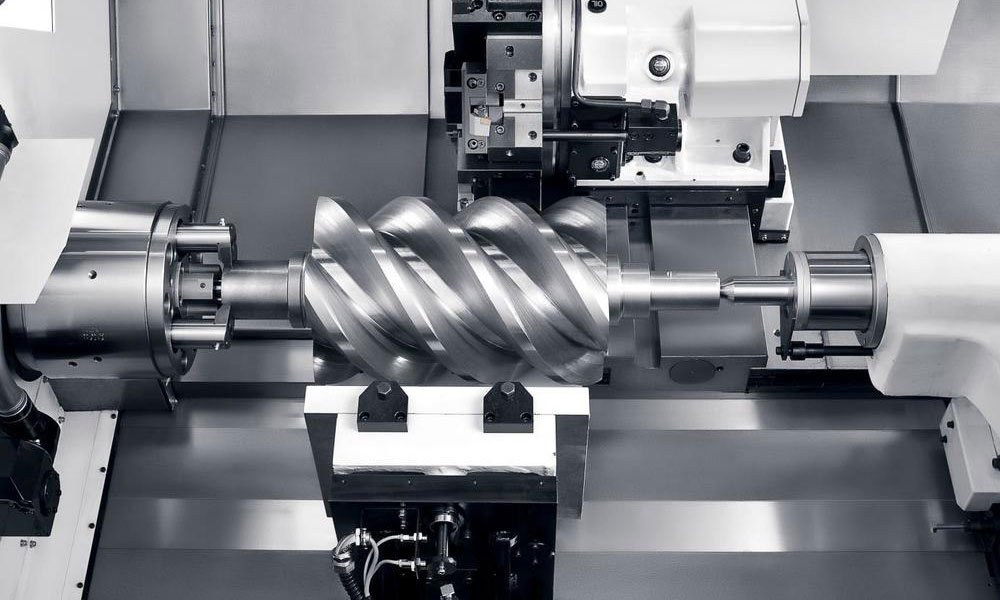

CNC Turning

CNC turning (lathe machining) is ideal for cylindrical parts such as shafts, rods, and bushings. It delivers precise diameters and smooth finishes, with flexible setups from 2-axis to 5-axis turning centers.

CNC Grinding

CNC grinding ensures high precision and superior surface finish. Commonly used for hardened metals and critical components such as bearings, molds, and precision tools, it provides excellent dimensional accuracy.

CNC Drilling

CNC drilling specializes in producing accurate holes of various diameters and depths. It is widely used in automotive, aerospace, and industrial machinery, ensuring repeatability and consistency in large batch production.

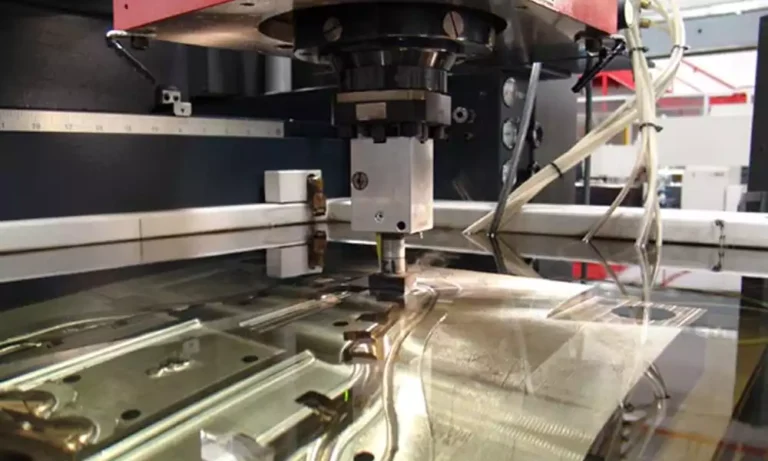

EDM

CNC EDM (Electrical Discharge Machining) uses electrical sparks to cut and shape hard metals or intricate geometries that are difficult to machine with traditional methods. It’s particularly valuable for molds, dies, and complex cavities.

CNC Cutting

Advanced CNC-controlled cutting methods such as laser and plasma cutting allow fast processing of sheet metals with clean edges. They are suitable for enclosures, brackets, and structural components requiring efficiency and precision.

CNC Machining Capabilities

— Tolerances: CNC Precision Machining Tolerances down to ±.0002″ (0.005mm).

— Surface treatment Roughness: Upon request

— Material Selection: Choose from 50+ engineering-grade plastics and metals

— Production: From 1 pcs to 10k+ pcs

— Served industries: Automotive Parts,Hardware Parts,Hydraulic Parts,Medical Parts and Machinery Parts.

— Services Offered: CNC Milling, CNC Turning, Surface Treatment.

Available Material

These are the Materials we recommend to you. Of course, we provide customized services.

Metals

Plastics

Common Materials grade Used in CNC Projects

• Aluminium 2007

• Aluminium 2017

• Aluminium2024

• Aluminium5052

• Aluminium 6060

• Aluminium 6061

• Aluminium6063

• Aluminium6068

• Aluminium 6082

• Aluminium 7075

• Copper E-Cu57 / E-Cu58

• Copper C260

• Copper C360

• Copper C1100

• Copper T27300

• Copper T27600,

• Copper T28200

- C3604

- C3602

- Brass Ms58

- Brass C36000

- H62(C28000, CuZn40)

- H65(C27000, CuZn35)

- H68(C26800, CuZn35)

- Hpb59(C37700, CuZn38Pb2)

- HPb62(C36000,CuZn36Pb3)

- Stainless Steel 303

- Stainless Steel 304

- Stainless Steel 304L

- Stainless Steel 316L

- Stainless Steel 316Ti

- Stainless Steel 416

- Stainless Steel420

- Stainless Steel430

- Marine-grade stainless steel

- Titan Grade 2 / 3.7035

- Titan Grade 5 / 3.7164 / 3.7165 / Ti-6Al-4V

- ABS

- Acrylic

- Industrial PEEK

- Nylon 6 / PA 6

- PC (Polycarbonate)

- PEEK glass-filled

- Polypropylene (PP)

- POM / Delrin acetal

- PTFE / Teflon

- PVDF / Polyvinylidene fluoride

- UHMW PE / Ultra-high-molecular-weight polyethylene

- 4130

- 4140

- 4340

- 40Cr

- 42CrMo

- 25CrMoV

- Q195

- Q215

- Q235/S235JRC

- 1010

- 1015

- 1018

- 1020

- 1045

- 1060

- 1117

- 12L14

- 12L15

- 9Cr2V Alloy Tool Steel

- 8Cr3 Alloy Tool Steel

- W18Cr4V High-Speed Steel

- Ordinary Carbon Tool Steel

- Oil-Hardened Cold-Work Alloy Steel

Available Finishes For CNC Machining Services

Choosing the right surface finishing method depends on factors such as material type, part design, functional requirements, and aesthetic preferences. Surface finishing not only enhances the visual appeal of parts but also improves their performance, durability, and functionality in various applications.

Below is a list of the available finishes for cnc machining projects. If you require a custom finish please contact: quote@alliedcn.com

CNC Machining Parts Case Studies

We have delivered tens of thousands of custom-machined, non-standard parts to clients worldwide. Explore our cases below to see why we are a reliable CNC machining partner for your projects.

Transmission Housing for Electric Vehicle

Complex aluminum housing requiring precise bore alignment and thermal stability for high-performance EV transmission.

- Multiple deep bores with positional tolerance of ±0.015mm

- Thin-walled sections (2.5mm) prone to vibration during machining

- Thermal stability requirements for consistent performance

- Used 5-axis simultaneous machining to maintain bore alignment

- Implemented adaptive toolpaths to minimize thin-wall deflection

- Applied stress-relief heat treatment before final machining

Aluminum 6061-T6

±0.015mm

Ra 0.8μm

12 days

Surgical Instrument Housing

Medical-grade stainless steel enclosure for portable surgical device with integrated cooling channels.

- Internal cooling channels with complex geometry

- Biocompatibility requirements (ISO 10993 certification)

- Mirror finish (Ra 0.4μm) on all external surfaces

- Utilized EDM for intricate internal channel machining

- Implemented multi-stage polishing process for mirror finish

- Conducted material traceability and certification

Stainless Steel 316L

±0.01mm

Ra 0.4μm

15 days

Satellite Mounting Bracket

Lightweight titanium bracket base with complex geometry for satellite communication systems.

- Weight reduction while maintaining structural integrity

- Complex 3D contours requiring 5-axis machining

- Stringent aerospace certification (AS9100)

- Topology optimization to minimize material usage

- 5-axis simultaneous machining for complex contours

- Full documentation for aerospace certification

Titanium Grade 5

±0.02mm

42%

18 days

CNC Machining Process

Submit your CAD files for DFM analysis and quote.

Free DFM consultation to optimize your design.

Machining using advanced 3-5 axis CNC equipment.

Rigorous testing with CMM and other tools.

Fast shipping with reliable supply chain.

Factory Environment

Why Choose Allied Metal CNC Machining as Your Business Partner ?

- Expertise: Extensive experience in cnc machining for the automotive industry.

- Quality: Certified to ISO 9001 and TS 16949, ensuring top-tier quality management.

- Capacity: Ability to produce up to 80 tons of high-quality parts per month.

- Technology: Equipped with more than 40 CNC machines, including large vertical gantry milling machine.

- Customer Focus: Dedicated to meeting the unique needs of our clients with tailored solutions and exceptional service.

Rapid Prototyping

Get functional prototypes in as little as 3-5 days to accelerate your product development cycle.

Cost Optimization

Our DFM analysis helps identify cost-saving opportunities without compromising quality.

Quality Assurance

Comprehensive inspection processes ensure every part meets your specifications and quality standards.

Global Delivery

We ship to customers worldwide with reliable logistics partners and real-time tracking.